The Ultimate Guide to Gearbox Predictive Maintenance: From Theory to ROI in 2025

Aug 31, 2025

gearbox predictive maintenance

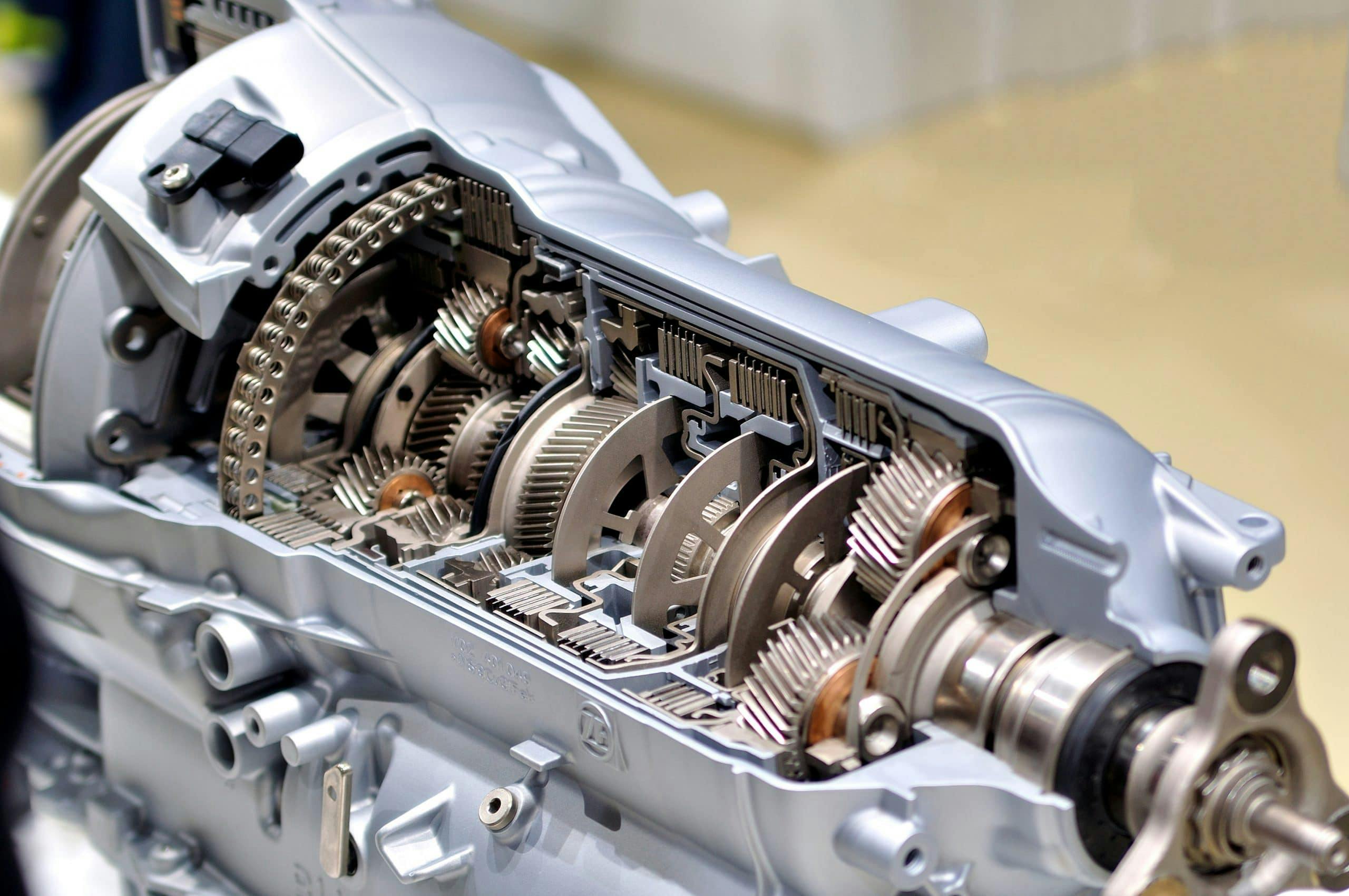

The sudden, jarring sound of a critical gearbox seizing is a sound no plant manager or maintenance professional ever wants to hear. It’s the sound of production grinding to a halt. It’s the sound of unplanned downtime, cascading failures, frantic calls for emergency repairs, and skyrocketing costs. For decades, maintenance teams have fought against this reality with a two-pronged approach: run-to-failure (reactive) or calendar-based (preventive) maintenance. But in 2025, there's a profoundly better way.

Welcome to the era of gearbox predictive maintenance (PdM). This isn't just another industry buzzword; it's a fundamental strategic shift in how we manage our most critical rotating assets. It’s about moving from a state of reacting to failures or guessing at asset health to a state of data-driven foresight.

This comprehensive guide will take you beyond the simple definitions. We will dive deep into the specific technologies, the practical implementation steps, the integration with modern AI and IIoT platforms, and the all-important ROI calculation that will get your leadership on board. This is your roadmap to transforming your maintenance operations from a cost center into a strategic competitive advantage.

Beyond the Basics: Why Preventive Maintenance for Gearboxes Falls Short

For years, preventive maintenance (PM) was hailed as the gold standard. The logic is simple: service or replace components on a fixed schedule—be it time, cycles, or mileage—to prevent them from failing in service. For a simple component, this can work. But for a complex, dynamic system like an industrial gearbox, the preventive model has critical, costly flaws.

The Problem with Averages: The Bathtub Curve Fallacy

The traditional "bathtub curve" of failure suggests that components have a high chance of early "infant mortality" failure, a long period of low-probability random failures, and then an increasing probability of "wear-out" failure. PM programs are designed to intervene just before that wear-out phase begins.

The problem? Extensive studies, including seminal work by United Airlines and the US Navy, found that only a small percentage (around 11-23%) of components actually follow this predictable wear-out pattern. Many gearbox failures are random, triggered by events like shock loads, contamination, or improper installation—things a calendar knows nothing about.

The Risk of Unnecessary Intervention

Performing major service on a perfectly healthy gearbox based on a calendar date is not just wasteful; it's risky. Every time a gearbox is opened, you introduce the risk of contamination, incorrect reassembly, or damage to seals. This can inadvertently induce an infant mortality failure on a component that would have otherwise run for thousands of more hours. You might be replacing a healthy, well-seated bearing with a new one that has a microscopic manufacturing defect, starting the failure clock all over again.

The Blind Spots of Time-Based Strategies

Preventive maintenance is blind to the actual condition of the asset. It cannot detect:

- The early stages of a bearing fault caused by a lubrication issue.

- A cracked gear tooth resulting from a momentary overload.

- Progressive misalignment that is slowly destroying couplings and bearings.

- Water contamination in the oil that is silently corroding internal components.

By the time a time-based PM inspection might catch these issues, significant damage has often already occurred. It misses the crucial window of opportunity for early, low-cost intervention.

The Core Principles of Gearbox Predictive Maintenance (PdM)

Predictive maintenance fundamentally changes the question from "When are we scheduled to work on this?" to "When does this asset need us to work on it?" It is the practice of using condition-monitoring tools and data analysis to track the live health of an asset, detect the earliest signs of degradation, and accurately predict when a failure is likely to occur.

Understanding the P-F Curve

The P-F Curve is the foundational concept of PdM. It illustrates the timeline of a failure.

(Image description: A graph showing asset condition degrading over time. The 'P' point (Potential Failure) is high on the curve, where condition monitoring can first detect a fault. The 'F' point (Functional Failure) is at the bottom, where the asset can no longer perform its function. The P-F interval is the window for proactive maintenance.)

- Point P (Potential Failure): This is the moment a potential failure becomes detectable. For a gearbox, this could be a microscopic pit on a bearing race that generates a specific high-frequency vibration signature, or a tiny metallic particle that shows up in an oil sample. The equipment is still running perfectly, but the seed of failure has been planted and is now visible to the right technology.

- Point F (Functional Failure): This is the point where the gearbox can no longer perform its intended function. A bearing has seized, a tooth has broken off, or the output shaft has sheared.

The entire goal of PdM is to identify Point P and then manage the "P-F Interval"—the crucial window of time between detection and failure. This interval gives you the power to plan and schedule the repair at the most convenient and cost-effective time, turning a potential catastrophe into a routine maintenance task. This proactive approach is a cornerstone of a successful Reliability-Centered Maintenance (RCM) strategy, which focuses maintenance efforts where they can have the greatest impact.

The Technology Stack: Key Condition Monitoring Techniques for Gearboxes

No single technology is a silver bullet. A robust gearbox PdM program uses a combination of techniques, each providing a unique window into the asset's health.

Vibration Analysis: The Gold Standard for Gear Failure Detection

If a gearbox has a heartbeat, vibration analysis is its EKG. It is the most powerful and widely used technology for detecting mechanical faults in rotating equipment.

-

How It Works: Highly sensitive sensors (accelerometers) are mounted on the gearbox housing, typically near the bearings. These sensors measure vibration in terms of acceleration, which is then processed by a data collector or an online system. The complex time-based signal is converted into a frequency spectrum using a mathematical process called Fast Fourier Transform (FFT). This spectrum separates the overall vibration into its individual frequency components, allowing analysts to pinpoint the exact source of a problem.

-

What It Detects:

- Gear Faults: The primary frequency generated by a gear set is the Gear Mesh Frequency (GMF), calculated as

Number of Teeth x RPM. A healthy gearbox shows a peak at the GMF and its harmonics (2x GMF, 3x GMF). A cracked or broken tooth will cause "sidebands" to appear around the GMF peak, spaced at the running speed of the faulty gear. This allows you to identify not only that there's a problem, but which specific gear is failing. - Bearing Defects: As rolling elements pass over microscopic flaws on the races, they generate distinct, high-frequency "ringing." These frequencies (BPFO, BPFI, BSF, FTF) are unique to the bearing's geometry and are often the very first sign of failure, appearing long before any audible or thermal indication.

- Imbalance: A heavy spot on a rotating component creates a strong vibration at 1x the running speed of that component.

- Misalignment: Misalignment between the motor and gearbox or the gearbox and the driven load is a major cause of failure. It typically appears as high vibration at 2x the running speed, often with significant axial (side-to-side) vibration.

- Looseness: Mechanical looseness of mounting bolts or worn-out bearings can cause a "truncated" vibration signal or multiple harmonics in the spectrum.

- Gear Faults: The primary frequency generated by a gear set is the Gear Mesh Frequency (GMF), calculated as

-

Technical Standards: For a more standardized approach, many organizations refer to guidelines like ASME's standards and topics on gears or ISO 10816 for general vibration severity limits. However, the true power of PdM comes from trending data over time, comparing the machine to its own healthy baseline rather than a generic standard.

Industrial Gearbox Oil Analysis: The Internal Health Check

If vibration analysis is the EKG, oil analysis is the blood test. The lubricant is a rich source of information about the condition of the internal components it protects. A comprehensive oil analysis program involves three key areas.

- Wear Debris Analysis: This goes beyond simply counting particles. Techniques like analytical ferrography use magnets and microscopes to separate and analyze the specific size, shape, color, and composition of wear particles. Are they fine, flat particles indicating normal rubbing wear? Or are they large, jagged steel particles indicating a gear tooth is spalling? Are there bronze flakes, pointing to wear in a worm gear or cage? This level of detail provides a definitive diagnosis of which component is in distress.

- Fluid Properties: Is the oil still fit for service? Analysis checks the viscosity—has it sheared down and lost its film strength, or has it oxidized and become too thick? It also measures the depletion of critical additives, such as the Extreme Pressure (EP) additives that protect gear teeth under heavy load.

- Contamination Analysis: Contaminants are a leading cause of gearbox failure. Oil analysis can detect water (which causes rust and depletes additives), coolant, dirt/silica (which is highly abrasive), and process fluids.

A single oil analysis report is a snapshot, but the real value lies in trending the results over time. This data is a critical health record for the equipment and a vital part of a holistic asset management program.

Infrared Thermography: Seeing Heat, Predicting Problems

Infrared (IR) thermography provides a fast, non-contact method of seeing the thermal signature of your equipment. Abnormal heat is often a precursor to failure.

- How It Works: An infrared camera detects thermal energy and converts it into a visual image, where different colors represent different temperatures.

- What It Detects:

- Friction: Overheating bearings or gear mesh due to poor lubrication or misalignment will show up as distinct hot spots.

- Cooling Issues: An IR scan can instantly reveal clogged cooler fins or a malfunctioning cooling fan.

- Electrical Faults: Before the gearbox, an IR scan of the drive motor can reveal overheating connections or windings.

- Best Practices: For thermography to be effective, it must be done consistently. Always compare a machine's temperature to identical machines under similar loads. Establish a regular inspection route and document findings with both a thermal and a standard digital photo for context. Thermography is an excellent screening tool; a "hot spot" warrants a deeper investigation with vibration or oil analysis.

Acoustic Emission (AE) Testing: Listening for the Cracks

Acoustic Emission is a more specialized but incredibly sensitive technology that "hears" the high-frequency stress waves generated by the earliest stages of material failure.

- How It Works: When a microscopic crack forms or propagates, or when two surfaces make high-friction contact under load, they release a burst of ultrasonic energy. AE sensors detect this energy.

- What It Detects: AE is exceptionally good at detecting subsurface crack initiation and growth in gear teeth and bearings. It is also highly effective for very slow-speed applications (e.g., under 10 RPM), where the energy from impacts is too low to be effectively measured by vibration analysis. It can provide the earliest possible warning of a fatigue-related failure.

The Modern Evolution: AI, IIoT, and CMMS Integration in 2025

The condition monitoring techniques above have existed for decades. The revolution of the 2020s is how we deploy them and what we do with the data. The convergence of the Industrial Internet of Things (IIoT), Artificial Intelligence (AI), and modern software platforms has made PdM more powerful, accessible, and scalable than ever before.

The Role of IIoT Sensors

Previously, collecting vibration or temperature data required a technician to walk a route with a handheld device, taking readings perhaps once a month. This created huge blind spots. A failure could easily initiate and progress to catastrophe between readings.

Today, low-cost, wireless, battery-powered IIoT sensors can be deployed on hundreds of assets. These sensors continuously monitor key parameters like tri-axial vibration and temperature, streaming data 24/7 to a central platform. This provides a complete, gap-free health record of your critical gearboxes.

The Power of AI and Machine Learning

Collecting massive amounts of data is one thing; making sense of it is another. This is where AI and machine learning create a step-change in capability. Human analysts are excellent, but they are a limited resource. AI can analyze data from thousands of assets simultaneously and tirelessly.

- Advanced Anomaly Detection: An AI model first learns the unique, healthy operational "signature" of each gearbox under its various speed and load conditions. Then, it continuously monitors for any deviation from this baseline. It can flag subtle, complex changes in the vibration or thermal signature that a human might miss or that wouldn't trigger a simple high/low alarm.

- Automated Diagnostics and Failure Pattern Recognition: The true power of modern AI predictive maintenance lies in its ability to move beyond just detecting a problem to diagnosing it. By training algorithms on vast datasets of known failures, the system can learn to recognize the specific data signatures associated with different failure modes—for example, distinguishing the pattern of an outer race bearing fault from that of gear mesh misalignment.

- Remaining Useful Life (RUL) Estimation: This is the pinnacle of predictive analytics. By analyzing the rate of degradation and comparing it to historical failure models, advanced AI algorithms can provide a probabilistic estimate of the RUL, or the time left until functional failure. This allows maintenance managers to make truly optimized decisions about when to intervene.

The Central Hub: CMMS Integration

Data and predictions are useless if they don't lead to action. The final, critical piece of the puzzle is integrating the PdM system with your Computerized Maintenance Management System (CMMS). This creates a closed-loop ecosystem for proactive reliability.

A modern CMMS software acts as the system of record and action for the entire maintenance operation. The integration works like this:

- Alert to Action: The AI-powered PdM platform detects a P-F curve starting on "Gearbox 101" and diagnoses it as a developing bearing fault with an estimated RUL of 45 days.

- Automated Work Order: This alert automatically triggers a new work order within the CMMS.

- Data-Rich Work Order: The work order is not just a simple "Inspect Gearbox 101." It is pre-populated with all the relevant data: the vibration trend data, the specific bearing fault frequencies identified, the latest thermal image, and the AI's diagnosis. This arms the technician with incredible insight before they even approach the machine.

- Closing the Loop: Once the repair is completed, the technician closes the work order in the CMMS, detailing the actions taken and parts used ("Replaced output shaft bearing P/N XYZ"). This information is fed back to the AI platform. This confirms the diagnosis was correct, enriching the dataset and making the AI model even smarter for the next prediction. This seamless workflow is powered by robust integrations between operational technology (sensors) and information technology (software).

A Practical Roadmap: How to Implement Gearbox Predictive Maintenance

Embarking on a PdM journey can seem daunting. By breaking it down into a logical, step-by-step process, any organization can achieve success.

Step 1: Asset Criticality Analysis

You cannot and should not monitor everything. The first step is to determine where to focus your efforts for the biggest return. Perform an asset criticality analysis by ranking all your gearboxes based on their impact on:

- Production: What happens if this gearbox fails? Does it shut down a single machine, an entire line, or the whole plant?

- Safety/Environmental: Could a failure create a safety hazard for personnel or result in an environmental release?

- Cost of Failure: What is the typical cost of repair, including parts, labor, and secondary damage?

Group your assets into categories (e.g., Critical, Important, Non-Essential). Your initial PdM program should focus exclusively on the "Critical" assets.

Step 2: Selecting the Right Technologies and Partners

For your critical gearboxes, determine the most likely failure modes. Are they prone to bearing failures? Lubrication issues? Overloads? This will guide your technology selection. A high-speed, critically-aligned gearbox will benefit most from continuous vibration analysis. A slow-moving, high-torque gearbox might be a better candidate for a combination of oil analysis and acoustic emission.

You also face a "build vs. buy" decision. Do you have in-house certified vibration analysts and reliability engineers? If so, you might "build" a program by purchasing sensors and analysis software. For most organizations, it's far more efficient and effective to "buy" a solution by partnering with a full-service provider that offers an integrated platform of sensors, AI software, and expert support, such as our Predict solution.

Step 3: Establishing a Baseline

Once your sensors are installed and your software is online, you must establish a healthy baseline. You cannot detect "abnormal" until you define "normal." This involves collecting data for a period (typically 2-4 weeks) while the gearbox is running under its normal operating conditions (various loads and speeds). This data forms the unique operational signature against which the AI and analysts will compare all future readings.

Step 4: Setting Alarms and Developing Workflows

Initially, simple threshold alarms can be set based on industry standards like ISO 10816. However, the real power comes when the AI platform learns the baseline and sets its own dynamic, multi-variate alarms that are far more sensitive.

Crucially, you must define the workflow for when an alarm is triggered.

- Who receives the notification (e.g., maintenance planner, reliability engineer)?

- What is the first step (e.g., review the data, take a confirmatory reading)?

- At what severity level is a work order automatically generated? Defining these processes within your work order software ensures that every alert is actionable and nothing falls through the cracks.

Step 5: Training and Culture Change

A PdM program is as much about people as it is about technology.

- Train your team: Technicians need to understand the basics of the technologies being used. They need to trust the data and the recommendations coming from the system.

- Shift the culture: The entire maintenance and operations culture needs to shift from a reactive, "firefighting" mindset to a proactive, planned, and data-driven one. This requires strong leadership and consistent communication about the program's goals and successes.

Quantifying the Value: Calculating the ROI of Gearbox PdM

A PdM program is an investment, and leadership will want to see the return. The ROI calculation is compelling because it contrasts the visible costs of PdM with the often-hidden but massive costs of reactive maintenance.

The Cost of Inaction (The Reactive Maintenance Model)

- Downtime Costs: This is the largest cost. Calculate the value of lost production per hour and multiply it by the hours of unplanned downtime caused by gearbox failures in a typical year.

- Secondary Damage: A bearing failure, if caught early, might cost $1,000 to fix. If it's run to failure, it can seize, destroying the shaft, gears, and housing—turning a $1,000 repair into a $50,000+ full gearbox replacement.

- Labor Costs: Emergency repairs mean overtime pay, premium rates for outside contractors, and pulling technicians away from other important work.

- Inventory Costs: The "just in case" mentality of reactive maintenance leads to bloated MRO storerooms full of expensive spare gearboxes and components that may never be used.

The Savings from PdM (The Proactive Model)

- Reduced Downtime: By converting unplanned outages into planned, scheduled repairs during non-productive hours, you reclaim massive amounts of production time.

- Lower Repair Costs: Early detection means smaller, simpler, and far cheaper repairs.

- Optimized MRO Inventory: A mature PdM program tells you what parts you will need and when you will need them. This allows for a shift to just-in-time parts ordering and a dramatic reduction in carrying costs. This is a key benefit of integrating PdM with your inventory management system.

- Increased Asset Lifespan: Instead of replacing components on a conservative schedule, you safely run them for their maximum useful life, extracting the full value from your capital investment.

A Simplified ROI Calculation Example

Let's imagine a critical gearbox where a failure causes 8 hours of downtime at a cost of $20,000/hour. This failure happens, on average, once a year. The reactive repair cost is $40,000.

- Annual Cost of Inaction: ($20,000/hr * 8 hrs) + $40,000 = $200,000

Now, let's implement a PdM solution.

- Cost of Investment (Year 1): $5,000 (sensors, software) + $2,000 (training/implementation) = $7,000

- Gains from Investment: The PdM system catches the failure early. The repair is planned for a weekend, causing 0 hours of production downtime. The early-stage repair only costs $5,000.

- Net Gain: $200,000 (Avoided Cost) - $5,000 (Proactive Repair Cost) = $195,000

ROI (Year 1) = ($195,000 Gain - $7,000 Cost) / $7,000 Cost = 26.8 or 2,680%

While this is a simplified example, it illustrates the powerful financial leverage that PdM provides. The payback period is often less than a year. For more on this, it's useful to consult resources on smart manufacturing from authorities like NIST.

Conclusion: Stop Guessing, Start Predicting

The industrial gearbox is a marvel of mechanical engineering, but it is not infallible. For too long, maintenance strategies have relied on guesswork and reaction. In 2025, the technology, the software, and the strategic framework exist to eliminate that uncertainty.

Gearbox predictive maintenance, powered by IIoT, AI, and seamless CMMS integration, is no longer a futuristic concept—it is an operational necessity for any organization that wants to be competitive, efficient, and resilient. It transforms maintenance from a defensive necessity into a proactive, data-driven engine for reliability and profitability.

The journey begins with a single step: choosing to move from reacting to the past to predicting the future. By understanding the health of your critical assets in real-time, you gain control over your operations, your budget, and your success.