Predict Failures Weeks Before They Happen

Sensor-agnostic predictive maintenance that works with your existing sensors, historians, and SCADA -- no proprietary hardware. Deploy in brownfield plants in under 14 days with no-code setup. PdM + CMMS bundled in a single platform.

TRUSTED AND SUPPORTED BY

Sensor-agnostic AI that works with your existing infrastructure

Predict is built for brownfield plants with existing sensors and data infrastructure. No rip-and-replace. No proprietary sensor lock-in. Our sensor-agnostic platform connects to any data source and starts delivering predictions in under 14 days -- no data science team required.

70% reduction in unplanned downtime

Early detection of anomalies allows you to schedule maintenance before failures occur, dramatically reducing emergency repairs and production losses.

Data-driven reliability strategies

Comprehensive analytics provide insights into failure patterns, equipment health trends, and maintenance effectiveness to guide your reliability program.

Advanced AI for industrial reliability

Predict uses machine learning algorithms specifically trained for industrial equipment to deliver accurate anomaly detection and actionable insights.

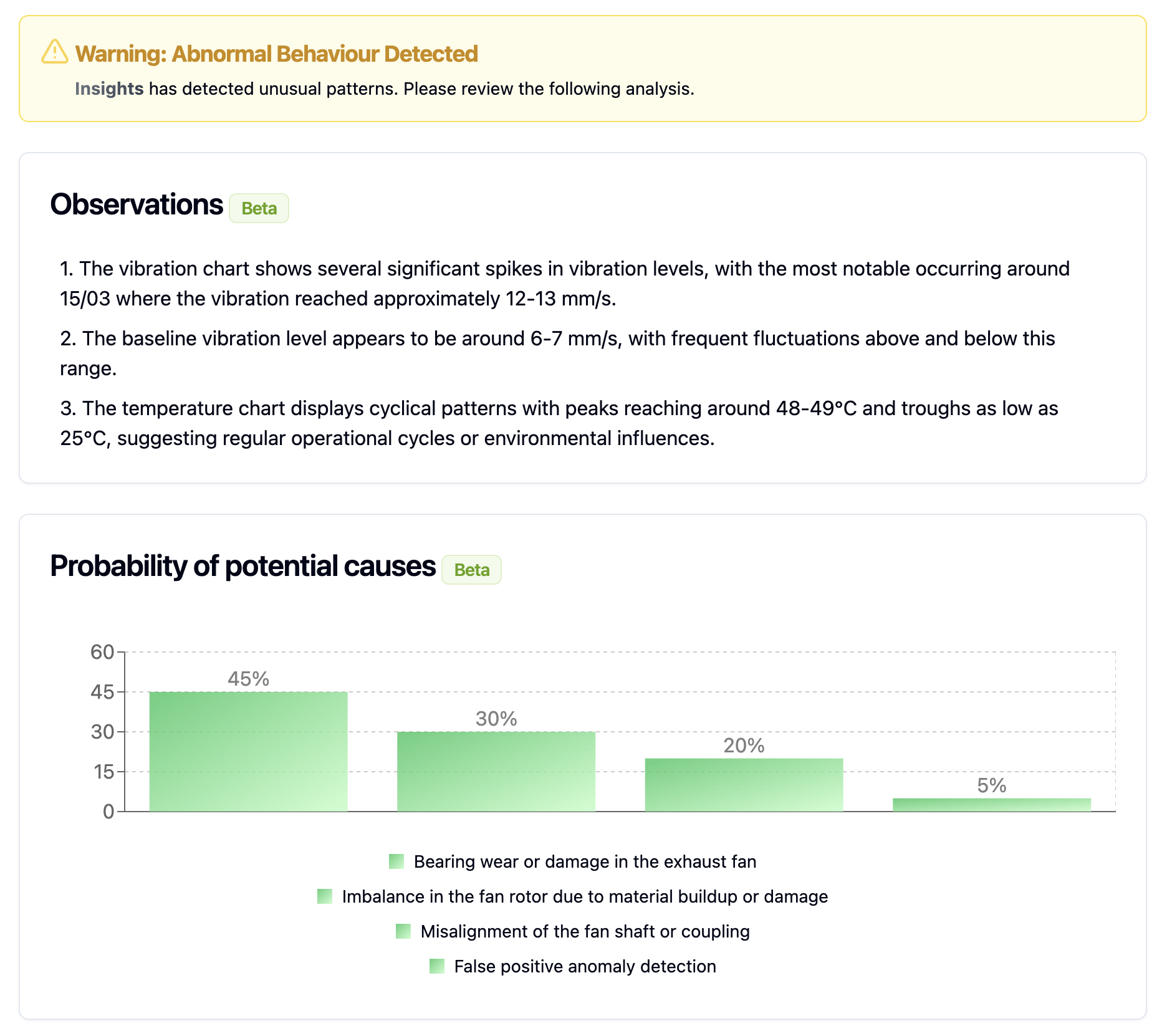

Early Anomaly Detection

Identify subtle changes in equipment behavior weeks before traditional monitoring methods would detect issues.

- Detection 3-5 weeks before failure

- Multivariate pattern recognition

- Severity assessment and prioritization

Sensor-Agnostic Integration

Works with any sensor brand, historian, or SCADA system. No proprietary hardware required. Designed for brownfield plants with existing infrastructure.

- Sensor-agnostic: any brand, any protocol

- Brownfield-ready with no-code setup

- PdM + CMMS in one unified platform

Advanced Analytics

Powerful visualization tools and reports that turn complex data into actionable reliability insights.

- Root cause analysis

- Asset health monitoring

- Remaining useful life estimation

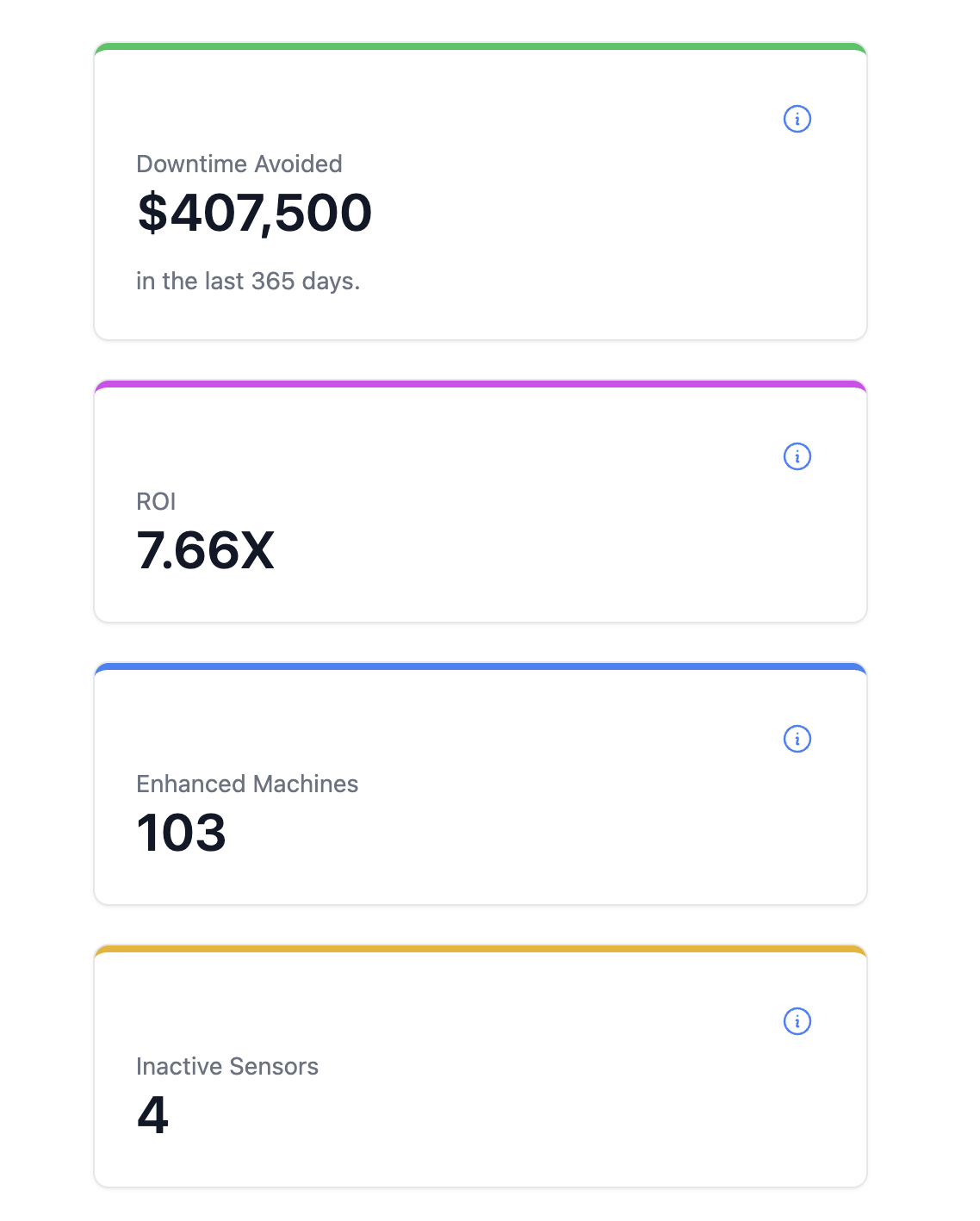

Proven ROI for reliability teams

Predict delivers measurable financial impact by preventing costly failures and optimizing maintenance resources.

Reduction in maintenance costs

Reduction in unplanned downtime

Return on investment

Months to positive ROI

How Predict works

Connect

Integrate with your existing data sources or deploy new sensors to monitor critical assets.

Learn

Our AI establishes baseline patterns for normal equipment operation from historical data.

Detect

Advanced algorithms identify subtle deviations and anomalies before they become critical issues.

Alert

Receive timely notifications with actionable insights about potential failures and their causes.

Improve

The system continuously learns from feedback and outcomes to enhance prediction accuracy over time.

Ready to transform your reliability program?

Contact our team to schedule a personalized demo and discover how Predict can help your organization prevent failures before they happen.

Factory AI Predict FAQ

Common questions about our AI predictive maintenance platform.