MTBF is Not Enough: The Real Guide to Mean Time Between Failures for 2025

Jul 17, 2025

mtbf

The alert flashes across your screen: "Line 3 Conveyor - Motor Failure." Your heart sinks. You just reviewed the reliability report last week, and that conveyor had a stellar Mean Time Between Failures (MTBF) of over 4,000 hours. It wasn't supposed to fail for at least another six months. As your team scrambles, production grinds to a halt, and you're left wondering: How did our key reliability metric lead us so astray?

This scenario is all too common. For decades, MTBF has been a cornerstone of maintenance and reliability engineering. It's a simple, universally understood metric. But in the complex, high-stakes industrial landscape of 2025, relying on MTBF alone is like navigating a supercar using a map from the 1980s. It gives you a general idea of where you've been, but it won't help you avoid the crash that's just around the corner.

This guide is designed for maintenance managers, reliability engineers, and operations leaders who understand that foundational metrics are important, but strategic application is what drives success. We will dissect MTBF, expose its critical flaws, and provide a clear, actionable roadmap for building a modern reliability program that goes far beyond a simple average. It's time to stop looking in the rearview mirror and start predicting the road ahead.

What is MTBF (Mean Time Between Failures)? The Foundational Definition

Before we can dismantle the conventional wisdom around MTBF, we must first build a rock-solid understanding of what it is—and what it isn't. At its core, MTBF is a measure of reliability for a specific piece of equipment or asset.

The Core Concept: A Measure of Reliability

Mean Time Between Failures (MTBF) represents the average elapsed time between one failure of a system and the next. The most critical word in that definition is average. It's a historical performance indicator that tells you, on average, how long you can expect a repairable asset to perform its intended function under normal operating conditions after one failure before it fails again.

The emphasis on "repairable" is crucial. We use MTBF for assets that can be fixed and returned to service, such as pumps, motors, compressors, and production machinery. For items that are discarded and replaced upon failure (like fuses, light bulbs, or single-use filters), we use a different metric called Mean Time to Failure (MTTF), which we'll explore later.

The MTBF Formula: How to Calculate It

The calculation for MTBF is straightforward, which is a primary reason for its popularity. The formula is:

MTBF = Total Uptime / Number of Failures

Let's break down the components:

- Total Uptime (or Total Operating Time): This is the total amount of time the asset was operational and performing its function during a specific period. It's crucial to subtract any planned downtime (like for scheduled maintenance) and unplanned downtime (the time the asset was down due to failure) from the total calendar time.

- Number of Failures: This is the total count of unplanned stoppages or breakdowns that required repair during that same period.

Accurately tracking these two variables is the key to a meaningful MTBF calculation. This is where a robust CMMS software becomes indispensable. Manually tracking uptime and failure counts on spreadsheets is prone to error, delays, and inconsistencies, rendering your MTBF calculations unreliable. A CMMS automates the logging of work orders, downtime, and operational hours, providing a clean, accurate dataset.

A Practical MTBF Formula Example

Let's put the formula into practice with a real-world scenario.

Imagine you're the maintenance manager for a bottling plant, and you want to calculate the MTBF for a critical bottle-capping machine, "Capper-01," over a single month (720 hours).

- Define the Period: We'll analyze a 30-day month, which has 720 hours (30 days * 24 hours/day).

- Identify Planned Downtime: The machine had 40 hours of planned downtime for a scheduled product changeover and a weekly sanitation cycle.

- Total Potential Operating Hours = 720 hours - 40 hours = 680 hours

- Log the Failures and Unplanned Downtime: During the month, Capper-01 experienced three unplanned failures:

- Failure 1: A sensor malfunctioned, causing 4 hours of downtime for diagnosis and replacement.

- Failure 2: The main drive belt snapped, resulting in 6 hours of downtime.

- Failure 3: A pneumatic valve seized, leading to 2 hours of downtime.

- Calculate Total Unplanned Downtime:

- Total Downtime = 4 hours + 6 hours + 2 hours = 12 hours

- Calculate Total Uptime:

- Total Uptime = Total Potential Operating Hours - Total Unplanned Downtime

- Total Uptime = 680 hours - 12 hours = 668 hours

- Calculate MTBF:

- Number of Failures = 3

- MTBF = Total Uptime / Number of Failures

- MTBF = 668 hours / 3 failures = 222.67 hours

So, the MTBF for Capper-01 for this month is approximately 223 hours. This means that, on average, the machine ran for 223 hours before a failure occurred.

The Critical Distinction: MTBF vs. MTTR vs. MTTF

Confusion between MTBF, MTTR, and MTTF is rampant and can lead to flawed analysis. Understanding their distinct roles is fundamental to any serious reliability discussion. They are three different legs of the same stool, each measuring a unique aspect of asset performance.

MTBF (Mean Time Between Failures): For Repairable Systems

As we've established, MTBF measures the average uptime between failures for assets you intend to fix. It is a direct indicator of an asset's inherent reliability. A higher MTBF generally means the asset is more reliable.

- Focus: Reliability (How long does it run?)

- Applies to: Pumps, motors, conveyors, CNC machines, vehicles.

MTTR (Mean Time to Repair): A Measure of Maintainability

Mean Time to Repair (MTTR) measures the average time it takes to diagnose and repair a failed asset and return it to operational status. It begins the moment the failure occurs and ends when the asset is back online. MTTR is a direct indicator of your maintenance team's efficiency and the effectiveness of your repair processes.

- Formula: MTTR = Total Downtime / Number of Failures

- Focus: Maintainability (How quickly can we fix it?)

- Applies to: The same repairable assets as MTBF.

Using our Capper-01 example:

- Total Downtime = 12 hours

- Number of Failures = 3

- MTTR = 12 hours / 3 = 4 hours

This means it takes your team, on average, 4 hours to get Capper-01 running again after a failure. A low MTTR is just as important as a high MTBF.

MTTF (Mean Time to Failure): For Non-Repairable Items

Mean Time to Failure (MTTF) measures the average lifespan of a non-repairable component. Since these items are replaced, not repaired, there is no "time between failures"—there is only one failure, which is the end of its life.

- Formula: MTTF = Total Hours of Operation / Total Number of Units

- Focus: Lifespan (How long does it last?)

- Applies to: Light bulbs, fuses, bearings (in some strategies), disposable filters, electronic components.

Example: You install 100 new LED light fixtures in your facility. Over the next 20,000 hours of operation, 50 of them burn out. The MTTF for these fixtures would be calculated based on the total operational hours of all units until they failed.

How They Work Together: The Availability Equation

The true power of these metrics is realized when you combine them to calculate Inherent Availability. Availability is the percentage of time an asset is actually capable of performing its function when it's needed. It's arguably the most important top-level metric for operations.

The simplified formula for inherent availability is:

Availability = MTBF / (MTBF + MTTR)

Let's calculate the availability for Capper-01:

- MTBF = 223 hours

- MTTR = 4 hours

- Availability = 223 / (223 + 4) = 223 / 227 = 0.9823

Availability = 98.23%

This single percentage tells a much richer story. It shows that, considering both its reliability (MTBF) and its maintainability (MTTR), Capper-01 is available to run 98.23% of its scheduled operating time. Now you have a powerful KPI you can use to set goals, track performance, and communicate with management.

The Strategic Flaw: Why MTBF Alone is a Dangerous Metric

If MTBF is so useful and foundational, why is the central theme of this article that it's "not enough"? Because relying on this single, simple average in a complex system is a recipe for disaster. It lulls you into a false sense of security by hiding critical details.

The "Average" Trap: MTBF Hides Critical Variability

The most dangerous flaw in MTBF is that it's a mean average. It tells you nothing about the distribution or pattern of failures.

Consider this analogy: A man who can't swim wants to cross a river that has an average depth of three feet. He logically concludes he can walk across safely. He takes his first few steps in the one-foot-deep shallows, but then he hits a ten-foot-deep channel in the middle and drowns. The average was statistically correct, but practically useless and ultimately fatal.

MTBF works the same way. Let's look at two assets, both with an MTBF of 1,000 hours over a 4,000-hour period:

- Asset A: Fails like clockwork at 1,000 hours, 2,000 hours, and 3,000 hours. This is a predictable wear-out pattern. Your PM strategy can be perfectly timed.

- Asset B: Fails at 100 hours, 150 hours, 250 hours, and then runs perfectly for the remaining 3,500 hours. The failures are clustered at the beginning (perhaps due to infant mortality or installation issues).

Both have the same MTBF, but Asset B is far more problematic and unpredictable in the short term. MTBF alone tells you none of this. To truly understand failure patterns, reliability engineers use more advanced statistical methods like Weibull analysis, which can help distinguish between early-life failures, random failures, and wear-out failures. For those looking to dive deeper, resources from organizations like ReliabilityWeb offer extensive knowledge on these advanced topics.

It Ignores the Severity and Cost of Failure

MTBF treats all failures equally. In the calculation, a 15-minute stoppage to reset a tripped sensor on a non-critical packaging machine is weighted exactly the same as a 10-hour catastrophic gearbox failure on your primary production line. Both are counted as "one failure."

This is a massive blind spot. The consequences of failure are what truly impact the business. A modern reliability strategy must incorporate a criticality analysis, ranking assets based on the impact their failure has on:

- Production output

- Safety

- Environmental compliance

- Repair cost

By layering criticality on top of MTBF, you can focus your resources where they matter most. An asset with a mediocre MTBF but high criticality deserves far more attention than an asset with a poor MTBF but low criticality.

It's a Lagging Indicator, Not a Predictive Tool

MTBF is, by its very nature, historical. It tells you what has already happened. It describes the past performance of an asset. While this is useful for benchmarking and long-term planning, it does absolutely nothing to help you prevent the next failure.

Driving your maintenance program using only MTBF is like trying to drive a car forward by looking only in the rearview mirror. You can see the road you've been on, but you have no idea about the stalled truck just around the bend. In 2025, the goal is not just to repair things efficiently after they break; it's to prevent them from breaking in the first place. This requires a shift from lagging indicators to leading, predictive insights.

Moving Beyond MTBF: Building a Modern Reliability Program in 2025

Recognizing the limitations of MTBF is the first step. The next is to build a more sophisticated, multi-layered reliability program that uses MTBF as one tool in a much larger toolbox. Here’s a four-step framework to elevate your strategy.

Step 1: Augment MTBF with OEE (Overall Equipment Effectiveness)

If MTBF is a single data point, Overall Equipment Effectiveness (OEE) is the full dashboard. OEE is a composite metric that measures manufacturing productivity by combining three key factors:

- Availability: (The part where MTBF lives) Does the machine run when it's supposed to? It accounts for unplanned and planned stops.

- Performance: When the machine is running, is it running at its ideal speed? It accounts for slow cycles and small stops.

- Quality: Of the units produced, how many meet quality standards? It accounts for rejects and rework.

OEE = Availability x Performance x Quality

By tracking OEE, you get a holistic view of an asset's contribution to the bottom line. You might have a fantastic MTBF (high Availability), but if the machine is running at 50% of its designed speed (low Performance) and 10% of its output is scrap (low Quality), it's still a poorly performing asset. OEE exposes these hidden losses that MTBF completely ignores.

Step 2: From Reactive to Proactive with Preventive Maintenance (PM)

The most direct way to improve your MTBF is to stop failures before they start. This is the realm of Preventive Maintenance (PM). A well-designed PM program involves performing scheduled maintenance tasks (e.g., lubrication, cleaning, adjustments, parts replacement) at specific time or usage-based intervals to reduce the likelihood of failure.

You can use your historical MTBF data as a starting point for setting PM frequencies. If a pump has an MTBF of 2,000 hours, you might schedule a PM inspection and lubrication service every 1,500 hours to intervene before the average failure point. As you collect more data, you can fine-tune these intervals. The goal is to find the sweet spot that maximizes reliability without performing excessive, unnecessary maintenance (over-maintenance).

Step 3: The Leap to Predictive Maintenance (PdM)

Preventive maintenance is a huge step up from reactive maintenance, but it's still based on averages and schedules, not the actual condition of the asset. The true game-changer in modern reliability is Predictive Maintenance (PdM).

PdM uses condition-monitoring technologies to monitor the real-time health of an asset and predict when a failure is likely to occur. Instead of relying on a historical average like MTBF, you're using live data to make decisions.

Common PdM technologies include:

- Vibration Analysis: Detects imbalances, misalignment, and bearing wear in rotating equipment like motors and pumps.

- Thermal Imaging: Identifies overheating components in electrical panels, motors, and mechanical systems.

- Oil Analysis: Assesses the condition of lubricants to detect contamination or degradation, indicating internal machine wear.

- Ultrasonic Analysis: Hears high-frequency sounds associated with air leaks, electrical arcing, and early-stage bearing failures.

With a Predictive Maintenance (PdM) strategy, an alert isn't a surprise; it's an early warning. You can plan and schedule the repair before the failure ever happens, turning a costly, unplanned downtime event into a quick, controlled maintenance action.

Step 4: The Ultimate Goal: AI and Prescriptive Maintenance

If PdM tells you a failure is coming, Prescriptive Maintenance (RxM) tells you what to do about it. This is the cutting edge of reliability for 2025 and beyond. By leveraging the power of Artificial Intelligence (AI) and machine learning, prescriptive systems analyze massive datasets from multiple sources (condition monitoring, CMMS work history, parts inventory, production schedules).

An AI Predictive Maintenance platform doesn't just say, "Bearing C-123 is showing signs of wear." It provides a prescriptive recommendation:

"Vibration signature on Motor 4B indicates a 92% probability of bearing failure within the next 150 operating hours. The optimal time to perform the repair is during the scheduled line changeover on Wednesday night to minimize production impact. Part #XYZ-789 is required; there are three in stock in the main storeroom, bin A-14. The standard operating procedure for this repair is SOP-1138."

This is the ultimate evolution beyond MTBF. It moves from a reactive, historical average to a proactive, specific, and optimized recommendation. It's not just about preventing failure; it's about optimizing the entire maintenance and operational workflow.

How to Systematically Improve Your MTBF (and Why It Still Matters)

Even in a world of AI and PdM, improving your baseline MTBF is still a worthy goal. A higher MTBF means your assets are fundamentally more reliable, which reduces the overall maintenance burden. Here’s how to do it systematically.

Foundational Data Collection: The Role of a Modern CMMS

You cannot improve what you do not measure accurately. The foundation of any reliability improvement program is clean, consistent, and accessible data.

- Ditch the Spreadsheets: Manual tracking is the enemy of good data. A modern, mobile CMMS is non-negotiable. It allows technicians to log failures, labor hours, and parts used directly from the plant floor on a tablet or phone. This eliminates data entry errors, captures information in real-time, and builds the rich historical dataset needed for analysis.

- Standardize Failure Codes: Create a clear, standardized library of failure codes. Instead of technicians writing "pump broke," they can select from specific codes like "Pump - Seal Leak," "Pump - Bearing Failure," or "Pump - Motor Overload." This structured data is essential for identifying recurring problems.

Conducting Root Cause Failure Analysis (RCFA)

Every unplanned failure that lowers your MTBF is a learning opportunity. Don't just fix the symptom; find the root cause. Root Cause Failure Analysis (RCFA) is a structured problem-solving method used to dig past the immediate cause of a failure to find the true underlying reason.

Common RCFA techniques include:

- The 5 Whys: A simple but powerful method of asking "Why?" repeatedly until you reach the fundamental cause.

- Fishbone (Ishikawa) Diagram: A visual tool to brainstorm potential causes across different categories (e.g., Man, Machine, Method, Material, Measurement, Environment).

For a deeper look at these methods, resources like iSixSigma's guide to the Fishbone diagram can be incredibly helpful. By performing RCFA on your most frequent or most critical failures, you can implement corrective actions that prevent the problem from ever happening again, permanently increasing that asset's MTBF.

Optimizing PM Schedules and Procedures

Use your MTBF and failure data to continuously refine your preventive maintenance program.

- Are failures happening just before a PM is due? Your PM interval might be too long.

- Are you performing PMs on an asset that never fails between tasks? Your PM interval might be too short, meaning you're over-maintaining and wasting resources.

- Are failures still occurring despite regular PMs? The PM tasks themselves may be ineffective or incomplete. Review the procedures to ensure they are targeting the actual failure modes.

Improving Spare Parts Management

A long wait for a critical spare part can dramatically increase your MTTR, which crushes your overall availability even if your MTBF is good. An effective inventory management system, integrated with your CMMS, is vital.

By analyzing failure data, you can identify the critical spares needed for your most important assets and ensure they are kept in stock. This ensures that when a failure does occur, your team has the parts they need to execute the repair quickly, minimizing downtime and getting the asset back to its uptime-accruing state.

What is a "Good" MTBF Rate? The Unhelpful Question

One of the most common questions managers ask is, "What is a good MTBF?" The simple, and perhaps frustrating, answer is: It depends. There is no universal "good" number. Asking this question is like asking "What is a good price for a vehicle?" without specifying if you're buying a scooter or a freightliner.

Benchmarking Within Your Industry

Context is everything. An MTBF of 500 hours might be excellent for a complex piece of tooling in a harsh industrial environment, while an MTBF of 50,000 hours might be considered poor for a simple circulation pump in a clean, stable setting.

The best way to find a relevant benchmark is to look within your specific industry. Professional organizations, such as the American Society of Mechanical Engineers (ASME), and industry trade groups often publish reliability standards and benchmark data. Comparing yourself to similar facilities with similar equipment provides a much more meaningful yardstick.

The Most Important Benchmark: Yourself

While industry benchmarks are useful for context, the most important benchmark is your own historical performance. The goal is continuous improvement.

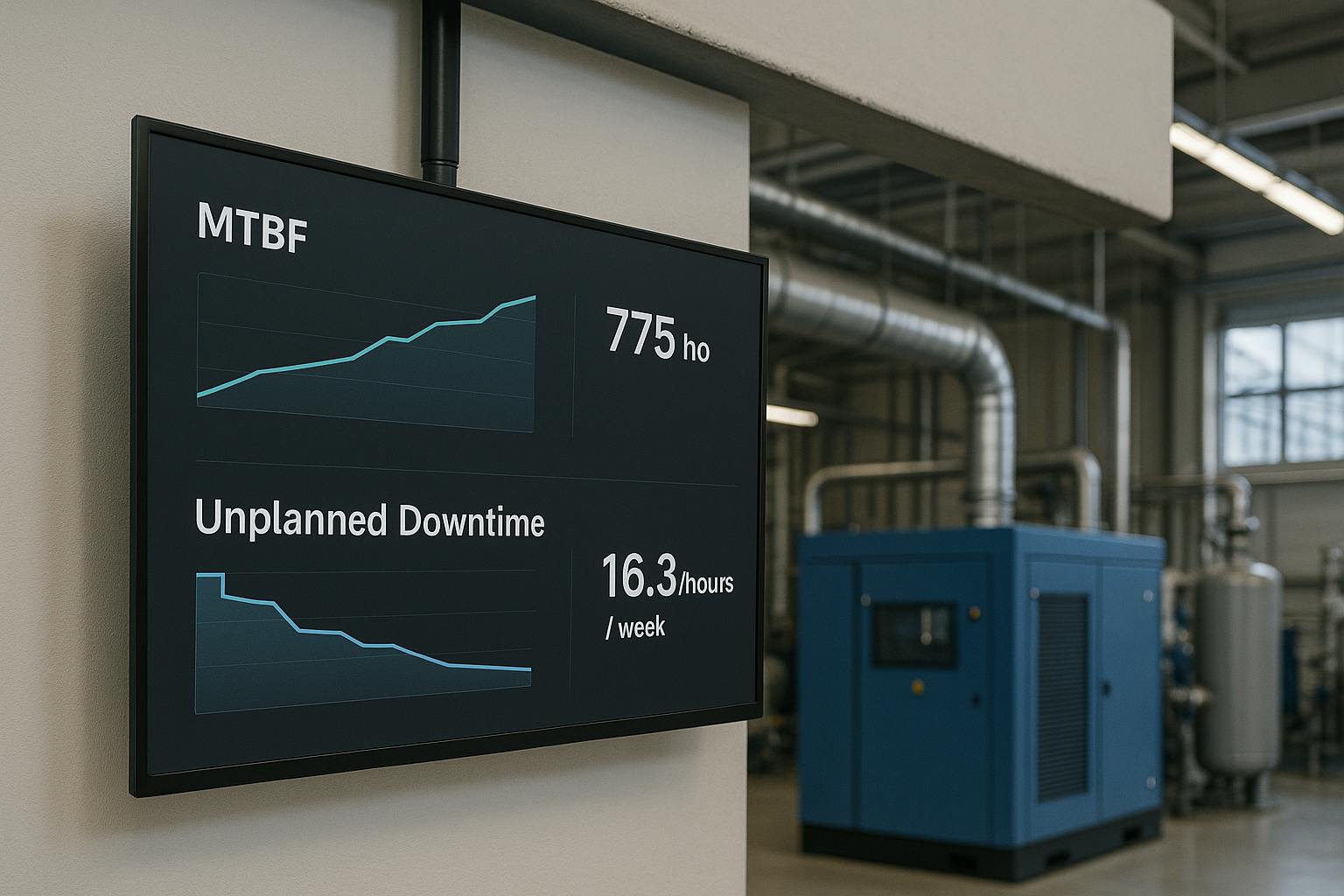

A "good" MTBF is one that is consistently trending upward for your critical assets. Instead of fixating on a single number, focus on the trend line. Are your reliability initiatives working? Is the MTBF for your top ten most critical assets higher this quarter than it was last quarter? That is the true measure of success.

Tying MTBF to Business Goals

Elevate the conversation from a technical metric to a business KPI. Instead of asking for a "good" MTBF, ask a better question: "What level of reliability, measured by MTBF and Availability, do we need to achieve our production targets and financial goals?"

Frame the discussion in terms of the cost of downtime, lost production capacity, and on-time delivery rates. When you can say, "Increasing the MTBF on Line 3 from 2,000 to 3,000 hours will reduce our unplanned downtime costs by $150,000 per year," you are speaking the language of the business. This transforms MTBF from a simple maintenance metric into a powerful tool for strategic decision-making.

Conclusion: From Metric to Mindset

Mean Time Between Failures is not an outdated or useless metric. It remains a fundamental component of reliability language. However, its power has been diluted by over-reliance and a lack of understanding of its inherent limitations.

In 2025, world-class organizations recognize MTBF for what it is: a starting point. It's a historical baseline, a single piece of a much larger puzzle.

The journey to operational excellence requires a profound shift:

- From focusing on a single average to understanding failure patterns and severity.

- From relying on lagging indicators of past failures to leveraging leading indicators that predict future events.

- From a reactive mindset of fixing what's broken to a proactive, predictive, and prescriptive culture of preventing failure altogether.

The question for today's industrial leaders is no longer "What is my MTBF?". The real question is, "How do I build an intelligent asset management strategy that uses every piece of data at my disposal to achieve near-perfect reliability?"

The tools and strategies exist. The time to move beyond the average is now.

Ready to move beyond lagging indicators and start predicting failures? Explore how our AI-powered predictive maintenance solutions can transform your operations and turn data into your most valuable asset.