Beyond the Band-Aid: Your Ultimate Guide to Root Cause Analysis (RCA)

Jun 2, 2025

Decision Making

It’s a scene played out daily in factories, plants, and facilities worldwide: a critical machine grinds to a halt. Alarms blare. Production stops. A frantic scramble ensues. Technicians rush in, identify a failed component – perhaps a burnt-out motor or a seized bearing – replace it, and with a collective sigh of relief, the line restarts. Problem solved, right?

Not quite.

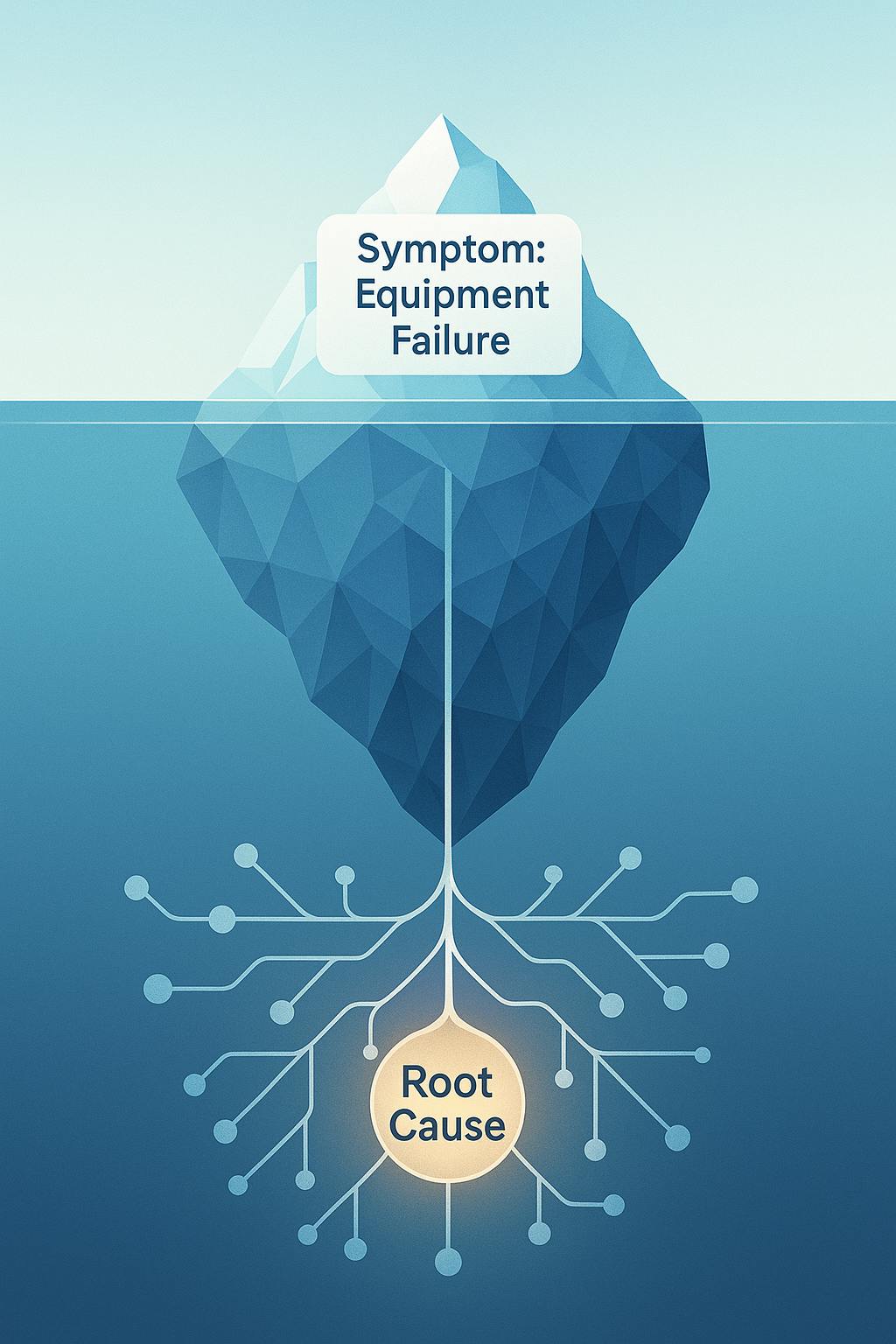

What if that same motor burns out again next month? And the month after? This is the classic symptom of "Band-Aid fixing" or treating the symptoms rather than the underlying disease. We celebrate the heroes who get the line running quickly, but often, the real culprit, the root cause of the failure, remains hidden, lurking, ready to strike again. This cycle of recurring problems is incredibly costly, leading to excessive downtime, wasted resources, frustrated teams, and missed production targets.

The antidote to this reactive spiral is a powerful, systematic problem-solving methodology known as Root Cause Analysis (RCA). It’s about moving beyond the immediate, obvious cause and digging deeper to find the fundamental reason why a problem occurred. It’s about asking not just "what happened?" but "why did it happen?" repeatedly, until you can go no further.

This definitive guide will provide you with a comprehensive understanding of Root Cause Analysis. We will explore its core principles, a step-by-step framework for conducting effective RCA, deep dives into the most common and practical methodologies, and how to foster a culture where RCA becomes second nature. Mastering RCA is about transforming your organization from one that constantly fights fires to one that prevents them, leading to more stable, reliable, and profitable operations.

Why Surface-Level Fixes Fail: The Staggering Cost of Not Doing RCA

Before we delve into the "how" of RCA, it’s crucial to understand the "why." The consequences of consistently failing to identify and address root causes are far-reaching and often severely underestimated:

- Recurring Problems & Chronic Downtime: This is the most obvious cost. If the underlying cause of a failure isn't fixed, the failure will happen again. Each recurrence means more lost production, more emergency repair costs, and more disruption.

- Wasted Resources: Continuously replacing the same component without understanding why it's failing is a massive drain on MRO (Maintenance, Repair, and Operations) inventory and technician time. You're spending money on parts and labor treating symptoms, not the cure.

- Increased Safety Risks: Often, the root cause of an equipment failure can also create a safety hazard. A recurring leak, if not properly addressed, could lead to slips, trips, and falls. An overheating component could pose a fire risk. Ignoring root causes can mean ignoring latent safety issues.

- Decreased Equipment Lifespan: Repeated failures and stresses on equipment, even if quickly repaired, accelerate wear and tear, leading to a shorter overall asset lifecycle and premature capital replacement costs.

- Reduced Product Quality: Process inconsistencies or equipment malfunctions stemming from unaddressed root causes can lead to product defects, rework, scrap, and ultimately, dissatisfied customers.

- Erosion of Team Morale: Constantly fighting the same fires is demoralizing for maintenance and operations teams. It creates a sense of futility and frustration when efforts don't lead to lasting improvements.

- Missed Opportunities for Improvement: Every unsolved problem is a missed opportunity to learn and make your processes more robust. RCA is a powerful engine for continuous improvement.

Treating symptoms is easy. Finding root causes takes effort, but the long-term payoff in terms of reduced costs, increased uptime, and improved safety is immense.

What is Root Cause Analysis? The Core Principles

Root Cause Analysis (RCA) is a systematic process for identifying the underlying causes of problems or incidents. A "root cause" is a fundamental, causal factor that, if removed or corrected, would prevent the problem from recurring.

Key principles of effective RCA include:

- Focus on Correction, Not Blame: RCA is about improving processes and systems, not pointing fingers at individuals. A blameless culture is essential for open and honest investigation.

- Systematic Approach: It’s not just brainstorming; it involves a structured methodology to ensure all potential causes are considered.

- Evidence-Based: Conclusions should be based on facts and data, not assumptions or opinions.

- Addressing the "Why": The core of RCA is to repeatedly ask "why" until the deepest, actionable cause is identified.

- Prevention-Oriented: The ultimate goal is to implement corrective actions that prevent the problem from ever happening again, or at least significantly reduce its likelihood.

It's important to distinguish between different types of causes:

- Direct Cause: The most immediate, obvious reason for the problem (e.g., "The motor burned out").

- Contributing Causes (Causal Factors): Factors that, in combination, led to the problem (e.g., "The motor was overloaded," "The cooling fan was blocked," "The wrong lubricant was used").

- Root Cause: The fundamental system or process failure that, if corrected, would prevent the contributing causes from aligning to create the direct cause (e.g., "Lack of a proper lubrication procedure," "Inadequate motor sizing during design," "No PM task to check cooling fan cleanliness").

You can fix the direct cause (replace the motor) and still have the problem recur if the root cause (e.g., lack of a lubrication PM) remains.

The RCA Process: A Step-by-Step Framework

While specific methodologies vary, a general framework for conducting RCA usually involves these key steps:

- Define the Problem Clearly & Concisely:

- What exactly happened? (The event) When did it happen? (Timing) Where did it happen? (Location) What was the impact? (Severity, cost, safety implications) A clear, agreed-upon problem statement is crucial. Avoid vague descriptions. For example, instead of "Line 3 stopped," use "Packaging Line 3 experienced an unplanned shutdown at 14:32 on June 2nd due to a failure of Conveyor Motor C-101, resulting in 2 hours of lost production."

- Gather Data & Evidence:

- This is the investigative phase. Collect all relevant information pertaining to the problem. This might include: Physical evidence (failed parts, photos, videos) Interviews with operators, technicians, and witnesses Maintenance logs and work order history (from your CMMS) Sensor data (from SCADA, PLCs, or dedicated monitoring systems) Standard Operating Procedures (SOPs) and training records Design specifications and equipment manuals The more comprehensive and accurate your data, the better your analysis.

- Identify Possible Causal Factors:

- Brainstorm all potential factors that could have contributed to the problem. This is where specific RCA methodologies come into play (discussed in the next section). Consider different categories of causes: equipment, process, people, environment, materials, management systems.

- Determine the Root Cause(s):

- Analyze the causal factors to identify which ones, if removed, would have prevented the incident. Often, there isn't a single root cause but a chain or combination of them. Continuously ask "Why?" for each causal factor until you can go no further or you reach a systemic issue.

- Develop & Implement Corrective and Preventive Actions (CAPA):

- Once root causes are identified, brainstorm and select effective solutions. Corrective Actions: Fix the immediate problem and address the identified root causes directly. Preventive Actions: Address systemic issues to prevent similar problems from occurring in other areas or on other equipment. Solutions should be SMART (Specific, Measurable, Achievable, Relevant, Time-bound).

- Verify Effectiveness & Monitor:

- After implementing solutions, monitor the situation to ensure the problem does not recur. Track relevant KPIs. If the actions were effective, you should see an improvement. If not, the RCA process may need to be revisited. Document the entire RCA process and its outcomes. This creates a valuable knowledge base.

Common RCA Methodologies In-Depth (The "How-To")

Several well-established methodologies can guide your RCA efforts. The best one to use often depends on the complexity of the problem and the resources available.

1. The 5 Whys

- Explanation: Perhaps the simplest and most widely known RCA technique. It involves repeatedly asking "Why?" (typically five times, but it can be more or less) to peel back layers of symptoms and arrive at the underlying cause.

- When to Use It Best: Excellent for relatively simple problems, human error issues, or as a quick first-pass analysis. Less effective for highly complex, multi-causal problems.

- Step-by-Step Guide (Manufacturing Example):

- Problem: Conveyor Motor C-101 on Packaging Line 3 failed.

- 1. Why did the motor fail? Answer: It overheated and the windings burned out.

- 2. Why did it overheat? Answer: The cooling fan was not providing adequate airflow.

- 3. Why was the cooling fan not providing adequate airflow? Answer: The fan shroud was clogged with dust and debris.

- 4. Why was the fan shroud clogged? Answer: There was no scheduled PM task to inspect and clean the motor fan shrouds.

- 5. Why was there no PM task to inspect and clean the shrouds? Answer: When the PM program was developed, this specific failure mode was overlooked for this asset class. (This is a systemic root cause).

- Pros: Simple to learn and apply, encourages deep thinking, requires no special tools.

- Cons: Can be overly simplistic for complex issues, results can vary depending on who is asking the questions, may lead to a single perceived root cause when multiple exist.

2. Fishbone Diagram (Ishikawa Diagram / Cause-and-Effect Diagram)

- Explanation: A visual tool that helps teams brainstorm and categorize potential causes of a problem. The "effect" (the problem) is the "head" of the fish, and the major categories of causes are the "bones."

- When to Use It Best: Excellent for team-based brainstorming, complex problems with multiple potential causes, and when you want to visualize the relationships between causes.

- Step-by-Step Guide (Manufacturing Example):

- Problem (Effect): High Defect Rate on Product Line A.

- Draw the "Head": Write "High Defect Rate - Line A" on the right side of a whiteboard and draw a horizontal arrow ("spine") pointing to it.

- Identify Major Categories (The "Bones"): Draw diagonal lines off the spine for common categories. In manufacturing, these are often the "6Ms":

- Manpower (People): Operator error, lack of training, fatigue.

- Method (Process): Incorrect procedure, outdated SOP, poor setup.

- Machine (Equipment): Tool wear, incorrect setting, sensor malfunction.

- Material: Defective raw material, incorrect material type.

- Measurement: Incorrect calibration, faulty gauge.

- Milieu (Environment): Temperature, humidity, lighting.

- Brainstorm Potential Causes: For each major category, the team brainstorms specific potential causes that could contribute to the high defect rate. For example, under "Machine," they might list "Worn cutting tool," "Incorrect speed setting," "Faulty sensor."

- Drill Down (Apply 5 Whys): For significant potential causes, the team can apply the 5 Whys to dig deeper.

- Pros: Visual and easy to understand, encourages comprehensive brainstorming, helps organize complex causal relationships.

- Cons: Can become very cluttered if not managed well, doesn't inherently prioritize causes.

3. Fault Tree Analysis (FTA)

- Explanation: A top-down, deductive failure analysis where an undesired state of a system (the "top event") is analyzed using Boolean logic (AND, OR gates) to combine a series of lower-level events. It maps out the logical relationships between failures and causes.

- When to Use It Best: Excellent for safety-critical systems, complex systems where the interaction of multiple failures can lead to a major event, and for quantitative risk assessment. Often used in aerospace, nuclear, and chemical industries.

- Step-by-Step Guide (Simplified Manufacturing Example):

- Top Event (Undesired State): "Emergency Stop System Fails to Activate."

- Identify Immediate Preconditions (using OR/AND gates): This could happen IF "E-Stop Button Fails" OR "Control Circuit Fails."

- Break Down Each Precondition: "E-Stop Button Fails" IF "Mechanical Jam" OR "Electrical Contact Failure." "Control Circuit Fails" IF "PLC Output Module Fails" AND "Backup Relay Fails." (This implies redundancy).

- Continue until Basic Events: Continue breaking down events until you reach basic, unanalyzable events (e.g., "component failure due to wear").

- Pros: Provides a clear graphical representation of failure paths, excellent for identifying single points of failure and common mode failures, can be used for quantitative analysis if failure probabilities are known.

- Cons: Can be very complex and time-consuming to develop for large systems, requires specialized knowledge, assumes events are binary (fail/succeed).

4. Pareto Analysis (80/20 Rule)

- Explanation: Based on the Pareto Principle, which states that roughly 80% of effects come from 20% of causes. This technique involves collecting data on different types of failures or problems and then charting them in descending order of frequency or impact.

- When to Use It Best: Excellent for prioritizing problems or causes when you have multiple issues to address. Helps focus efforts on the "vital few" causes that are responsible for the majority of the problems.

- Step-by-Step Guide (Manufacturing Example):

- Problem: Identify the most common reasons for unplanned downtime on Packaging Line 3 over the last quarter.

- Collect Data: Gather work order data for Line 3, categorizing the reason for each downtime incident (e.g., Motor Failure, Sensor Fault, Jammed Conveyor, Pneumatic Issue, Control System Fault).

- Tally Frequencies/Impact: Count the number of occurrences for each category, or sum the total downtime hours for each.

- Create a Pareto Chart: Create a bar chart with categories on the X-axis (ordered from highest to lowest frequency/impact) and frequency/impact on the Y-axis. Add a line graph showing the cumulative percentage.

- Identify the "Vital Few": The chart will visually show which 2-3 categories are causing ~80% of the downtime. These are your priority areas for more detailed RCA (using 5 Whys or Fishbone).

- Pros: Simple to understand and implement, visually highlights the most significant problems, data-driven approach to prioritization.

- Cons: Relies on historical data (which may not predict future issues), doesn't identify root causes itself but rather prioritizes areas for RCA.

Building an RCA Culture: Beyond the Tools

Successfully implementing RCA is about more than just learning the methodologies; it requires fostering a culture of inquiry, learning, and continuous improvement.

- Leadership Buy-in and Support: Management must champion RCA, provide resources, and encourage a blameless environment.

- Cross-Functional Teams: Involve people from different departments (operations, maintenance, engineering, quality) to get diverse perspectives.

- Training and Facilitation: Train teams in RCA methodologies and have skilled facilitators to guide complex analyses.

- Blameless Reporting: Encourage open reporting of incidents and near-misses without fear of punishment. The focus should be on system improvement.

- Action Tracking and Follow-up: Ensure that corrective actions identified through RCA are implemented, tracked, and their effectiveness verified. A good CMMS is invaluable here.

- Share Lessons Learned: Communicate the findings and improvements from RCAs across the organization to prevent similar issues elsewhere.

Common Pitfalls in RCA (And How to Avoid Them)

- Stopping Too Soon (Symptom Fixing): Not asking "Why?" enough times.

- Blame Culture: Focusing on who made an error rather than why the system allowed the error to occur.

- Lack of Data: Relying on assumptions instead of gathering evidence.

- Scope Creep: Trying to solve too many problems at once or making the problem definition too broad.

- Jumping to Solutions: Identifying a solution before the true root cause is understood.

- Failure to Implement or Verify Actions: The RCA is useless if the recommendations aren't acted upon.

RCA in the Age of Data and AI: The Path Forward

Traditional RCA methodologies are robust and proven. However, in the modern data-rich environment of Industry 4.0, they can be supercharged.

- Data-Driven Investigations: Modern CMMS systems, like those offered by Factory AI, provide a wealth of historical data on asset performance, work orders, and failure modes. This data is invaluable during the "Gather Data" phase of RCA. Platforms that integrate with PLCs and SCADA systems can provide even richer contextual data.

- AI-Assisted Pattern Recognition: For highly complex problems with vast datasets, AI and machine learning algorithms can help identify subtle correlations and patterns that humans might miss. While AI doesn't replace the critical thinking of RCA, it can be a powerful assistant in sifting through data to pinpoint potential areas of concern or validate hypotheses. (For example, an AI system might identify that a specific combination of operational parameters often precedes a certain type of SCADA alarm, guiding the RCA team's investigation).

- From Reactive RCA to Proactive Prediction: The insights gained from thorough RCAs are critical inputs for building effective Predictive Maintenance (PdM) models. When you truly understand why assets fail, you can better configure your systems to predict those failures.

While Factory AI doesn't offer a specific RCA software tool itself, our philosophy of leveraging data and AI to drive operational excellence aligns perfectly with the goals of RCA. The better you understand your failures through RCA, the more effectively you can use advanced platforms to prevent them in the future.

Conclusion: From Firefighting to Future-Proofing

Root Cause Analysis is not a one-time event; it’s a mindset and a continuous process. It's the commitment to look beyond the immediate fix and invest the effort to understand the deep-seated reasons why problems occur. By mastering the principles and methodologies of RCA, you empower your organization to break free from the costly jcycle of recurring failures. You move from a reactive state of constant firefighting to a proactive state of control, learning, and continuous improvement.

The journey to operational excellence is paved with a deep understanding of your processes and assets. RCA is your most powerful tool for gaining that understanding and building a more reliable, efficient, and safer future for your facility.

Tim Cheung

Tim Cheung is the CTO and Co-Founder of Factory AI, a startup dedicated to helping manufacturers leverage the power of predictive maintenance. With a passion for customer success and a deep understanding of the industrial sector, Tim is focused on delivering transparent and high-integrity solutions that drive real business outcomes. He is a strong advocate for continuous improvement and believes in the power of data-driven decision-making to optimize operations and prevent costly downtime.