TRUSTED AND SUPPORTED BY

We make it easy to analyse, diagnose, and improve asset availability

Our system does the hard work so you don't have to. We present you the insights to help make the right thing to do, the easiest thing to do.

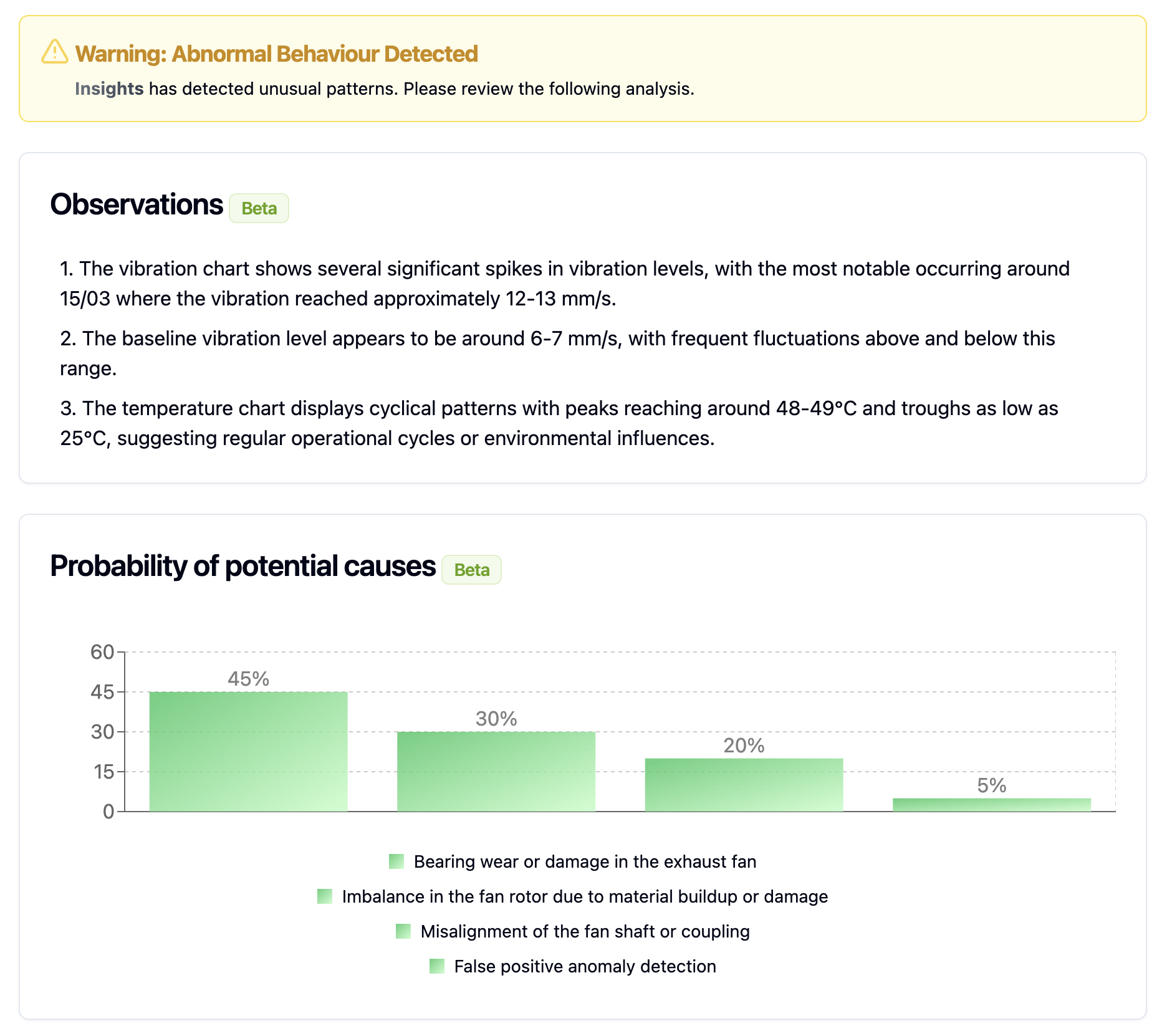

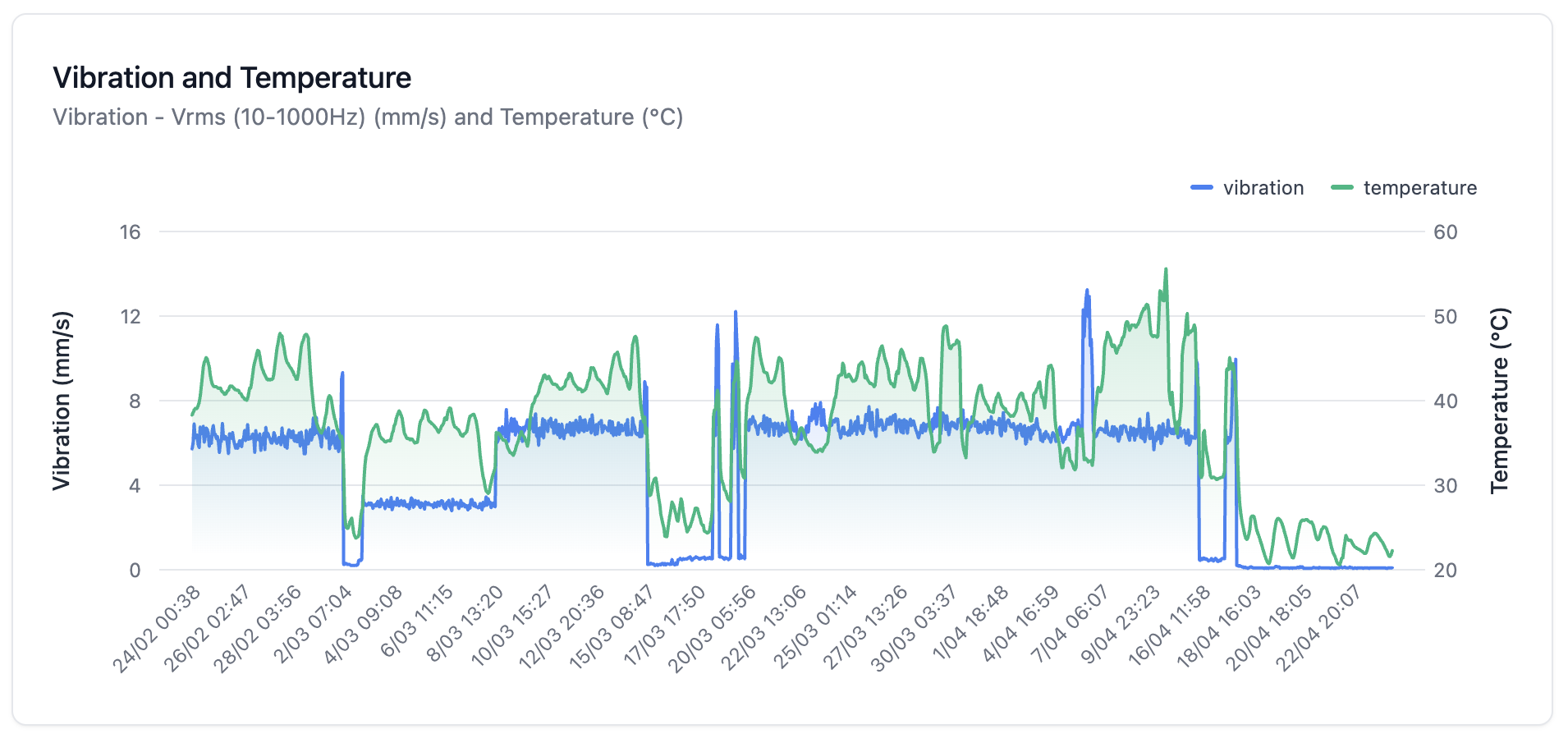

Anomaly detection

Our straightforward visuals empower teams to proactively tackle asset issues before they escalate into critical problems.

In-depth monitoring

Gain insights into the performance of pumps, fans, conveyors, and other equipment. Identify potential failure risks and receive notifications for issues that demand your immediate attention.

Predictive maintenance delivers value

Working with clients across various industries, we're demonstrating how predictive maintenance can help you mitigate unplanned downtime and prevent asset failures.

Reduction in maintenance costs

Reduction in breakdowns

Our Products

Comprehensive solutions for your predictive maintenance needs

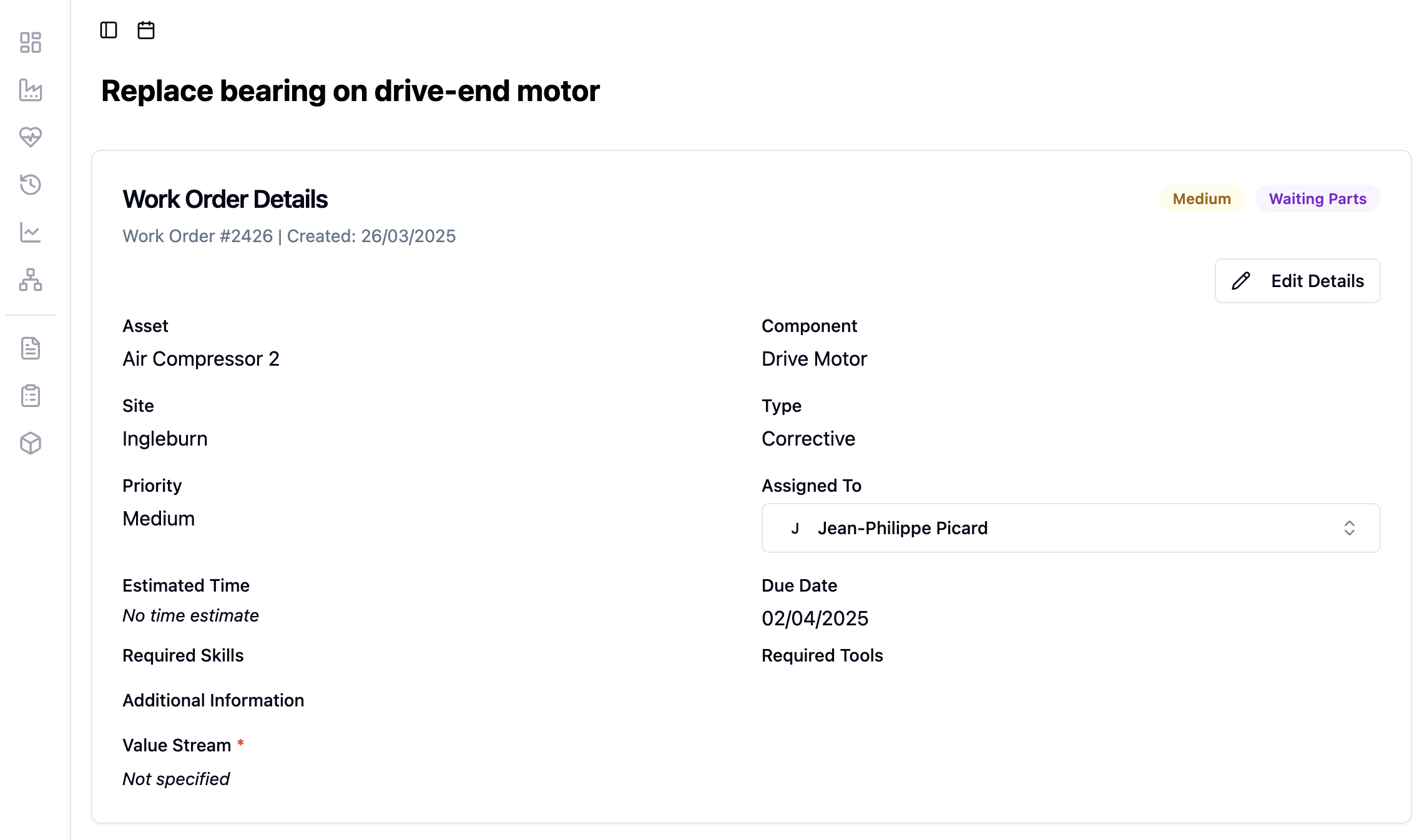

Predict

Anomaly Detection Platform

Our flagship predictive maintenance platform uses advanced machine learning to detect anomalies before they cause failures. Monitor critical assets in real-time and receive actionable alerts.

Starting at $500 per monitoring point with volume discounts available

Works with various data sources including sensors, historians, and PLCs

Includes our Prevent CMMS at no additional cost

Prevent

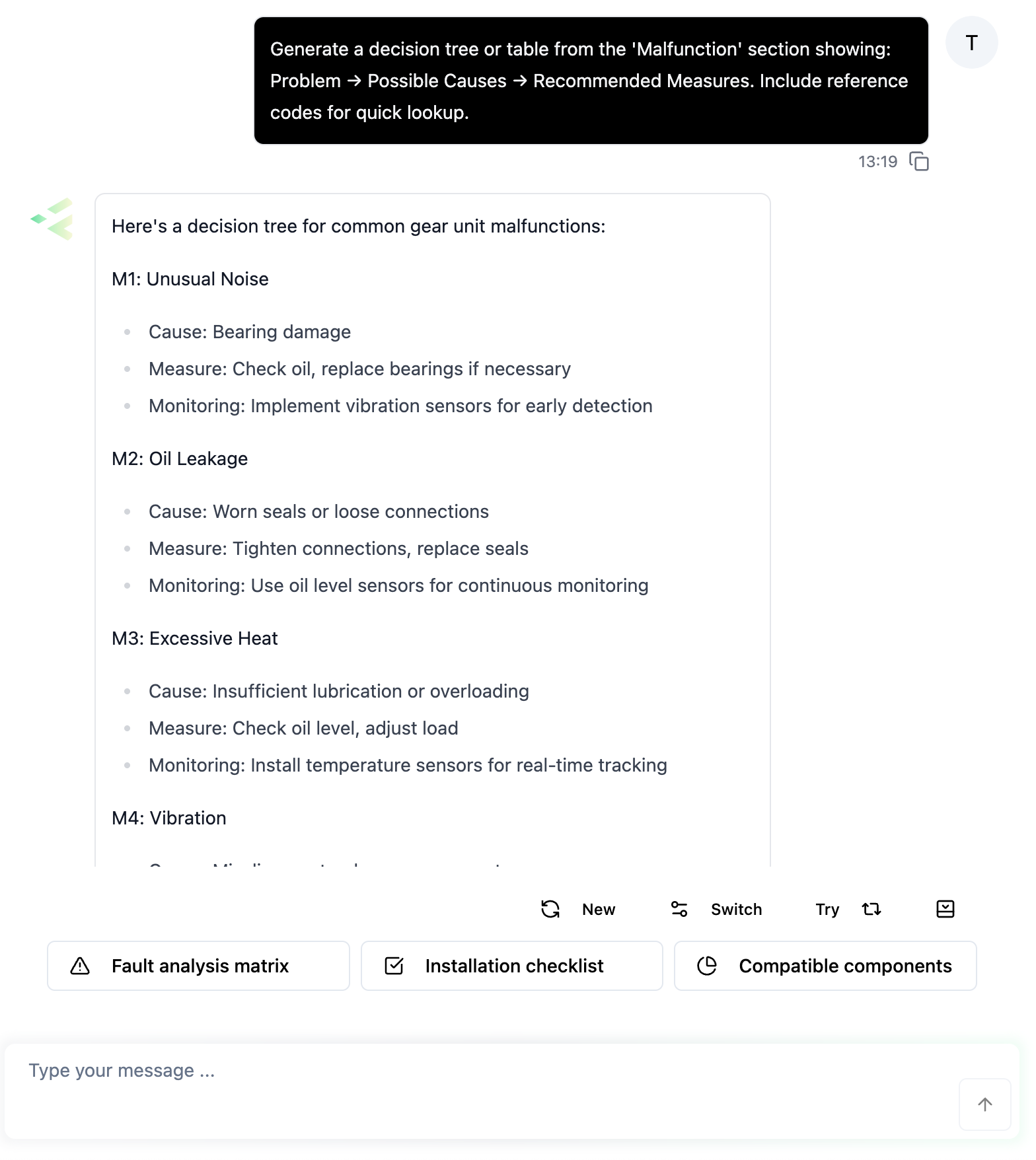

AI-Powered CMMS

Streamline your maintenance operations with our intelligent computerized maintenance management system. Generate work orders, manage assets, and optimize your maintenance schedule.

Free plan available for small teams

Business plan at $35/user/month (billed annually)

AI-powered work order generation and scheduling

Ready to get started? Let's speak

Start free. Discover the power of predictive maintenance and see the benefits for yourself.

Designed for maintenance and reliability teams of all sorts and sizes

Our solution can add value to teams that are still early in their journey to digitisation.

Reliability Engineers

Tired of disconnected problems that often stay in silos?

Your job shouldn't be playing detective after equipment failures.

Our platform helps you predict issues before they happen, analyze root causes, and create a centralized knowledge base for your team. With our AI-powered insights, you can finally see how everything fits in the production.

Maintenance Coordinators

Maintenance & Reliability Leaders

Frequently Asked Questions

We've got everything you need to get started on your predictive maintenance journey.