TRUSTED AND SUPPORTED BY

The Cost of Poor Equipment Maintenance

Unplanned downtime and equipment failures can cost millions in lost production and emergency repairs.

Unexpected Equipment Failures

Reactive maintenance leads to costly emergency repairs and production losses.

Shortened Equipment Life

Poor maintenance practices reduce equipment lifespan and increase replacement costs.

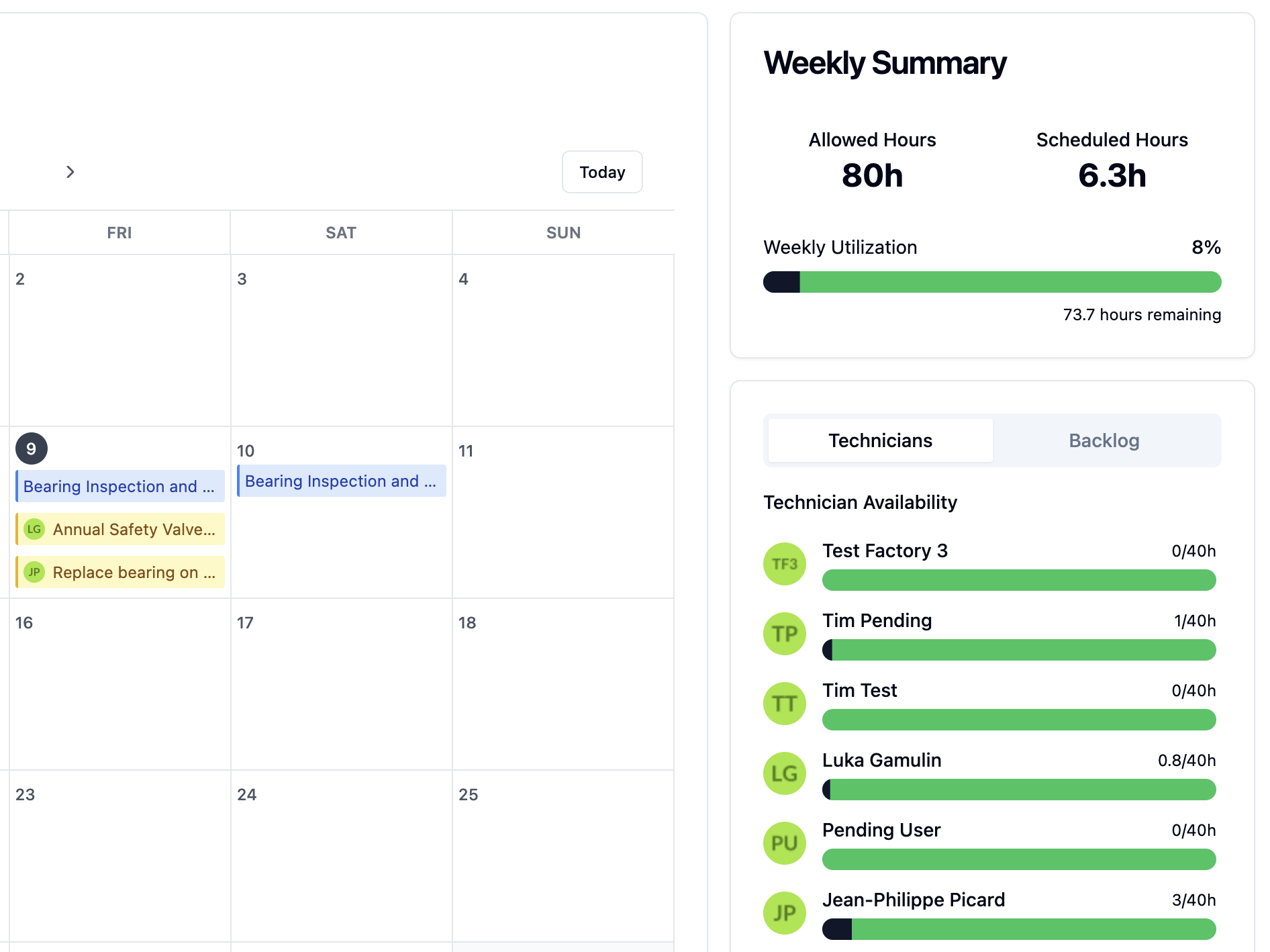

Inefficient Resource Allocation

Manual scheduling leads to wasted technician time and delayed maintenance.

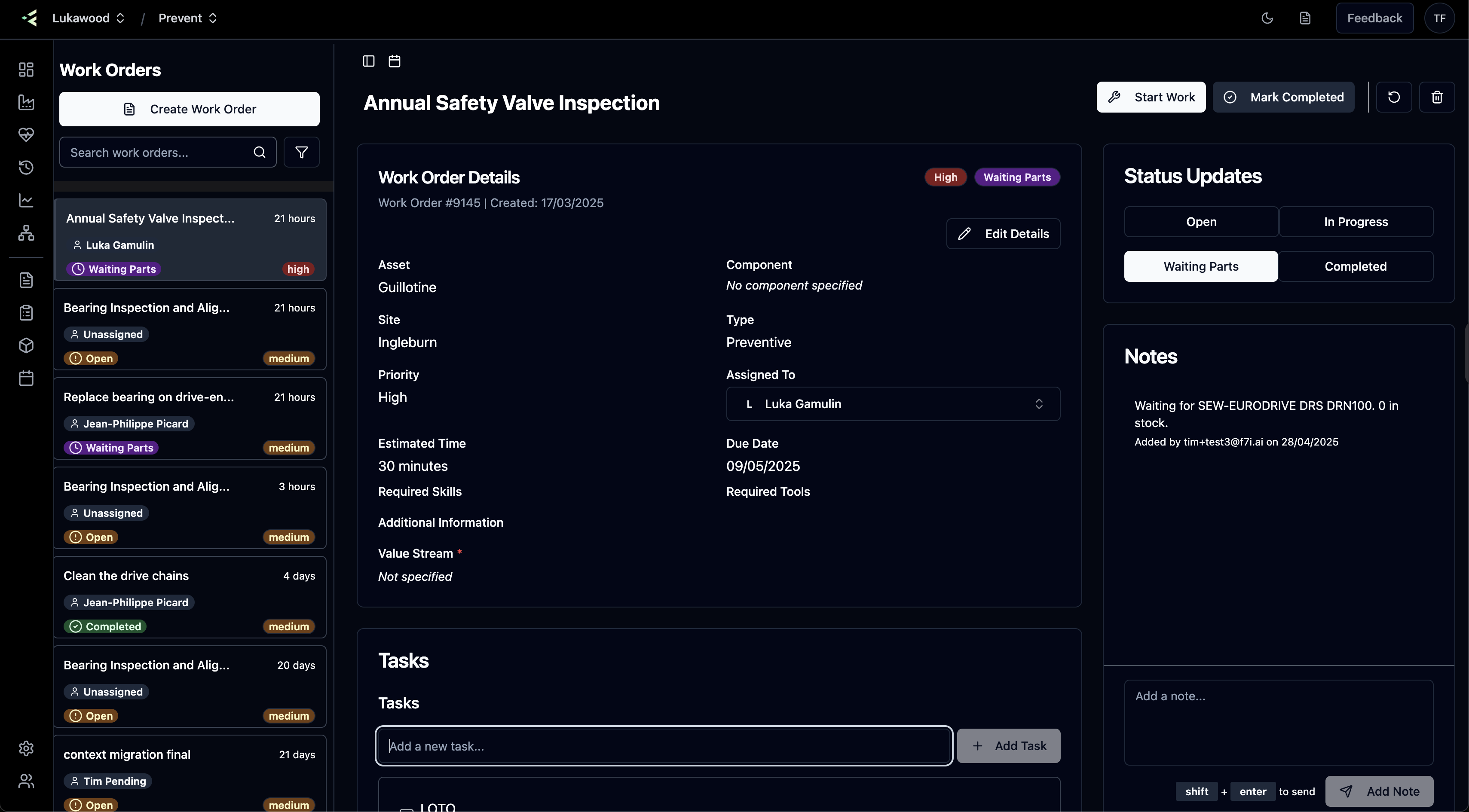

Comprehensive Equipment Maintenance Features

Prevent combines predictive maintenance, real-time monitoring, and optimized scheduling to keep your equipment running at peak performance.

Predictive Maintenance

AI-powered insights to prevent equipment failures before they happen.

- Real-time equipment monitoring

- Failure prediction algorithms

- Condition-based alerts

Maintenance Optimization

Smart scheduling and resource allocation for efficient maintenance.

- AI-powered scheduling

- Resource optimization

- Parts inventory management

Equipment Protection

Comprehensive maintenance strategies to extend equipment life.

- Preventive maintenance plans

- Performance monitoring

- Compliance tracking

Proven Results in Equipment Maintenance

Organizations using Prevent have achieved significant improvements in equipment reliability and maintenance efficiency.

Reduction in unplanned downtime

Extended equipment life

Lower maintenance costs

Faster issue resolution

Ready to optimize your equipment maintenance?

Contact our team to schedule a personalized demo and discover how our software can help you improve equipment reliability and reduce maintenance costs.

Frequently Asked Questions

We've got everything you need to get started on your predictive maintenance journey.