The Top 10 Objections to Predictive Maintenance (And How to Overcome Them)

Jun 23, 2025

Predictive Maintenance

Introduction

Imagine a world where critical machinery in your plant never suffers an unexpected breakdown. No spoiled batches of dairy, no frantic overnight repairs on a baked goods production line, no missed delivery deadlines for seafood.

For maintenance and reliability professionals in manufacturing, this isn't a distant dream; it's the tangible promise of predictive maintenance software. Yet, despite its undeniable benefits, many plant managers and site reliability engineers still encounter significant hurdles when considering its adoption. These objections, often rooted in past experiences, budget constraints, or perceived complexity, can seem insurmountable. But what if these perceived barriers are actually opportunities? What if a modern approach to predictive maintenance can not only overcome them but deliver a rapid return on investment (ROI)?

The Pervasive Problem: Unplanned Downtime in Agri-Food

In the dynamic and demanding environment of agri-food manufacturing – be it seafood processing, dairy production, baked goods, or the fast-paced world of FMCG – equipment uptime is paramount. A single unplanned outage can lead to enormous financial losses, product spoilage, compromised hygiene, and severe damage to brand reputation. Traditional maintenance strategies, whether reactive maintenance (fixing it when it breaks) or time-based preventive maintenance software, often fall short. Reactive maintenance is inherently costly and inefficient, turning every breakdown into an emergency. Preventive maintenance, while better, can still lead to unnecessary interventions and often misses the early, subtle signs of impending failure. You can learn more about the crucial differences in our article, Predictive Maintenance vs. Preventive Maintenance.

The true cost of unplanned downtime in food processing is staggering, often running into hundreds of thousands of pounds per hour. This isn't just about lost production; it encompasses wasted raw materials, overtime for emergency repairs, contractual penalties for missed deliveries, and the long-term erosion of customer trust. For an industry operating on tight margins and under stringent hygiene regulations, such disruptions are simply unsustainable.

Consider the intricacies. A sudden breakdown in a refrigeration unit within a seafood processing plant could lead to an entire batch being compromised, incurring significant financial loss and potential regulatory headaches. Similarly, a failure in a critical oven in a baked goods factory can halt production, forcing a complete line shutdown and impacting supply chains. The food and beverage industry operates with highly perishable goods and strict food safety regulations, making reliable operation absolutely non-negotiable. This is where predictive maintenance for FMCG and other agri-food sectors offers a lifeline.

The Crucial Insight: Modern PdM Transforms Objections into Opportunities

The good news is that the landscape of predictive maintenance has evolved dramatically. What might have been true for early, rudimentary systems no longer applies to today's advanced, AI-driven solutions. The core insight is this: the objections to predictive maintenance are often based on outdated assumptions or a lack of understanding of modern capabilities. By addressing these concerns head-on, manufacturers can unlock the profound benefits of true asset health monitoring. Modern predictive maintenance software, especially that tailored for the maintenance software for food and beverage industry, offers a clear pathway to enhanced reliability, significant cost savings, and a crucial competitive edge.

The journey from a reactive or time-based approach to a truly predictive one is about embracing data and artificial intelligence. It's about moving from guesswork and scheduled interventions to precise, condition-based actions. This shift is not merely technological; it's a strategic business decision that directly impacts profitability and operational resilience. As noted by industry experts, embracing advanced maintenance strategies is key to remaining competitive in a rapidly evolving manufacturing landscape. Reliabilityweb.com frequently discusses how embracing such technologies drives significant operational improvements.

Overcoming the Hurdles: The Top 10 Objections and Their Solutions

Let's dissect the most common objections heard on the plant floor and demonstrate how a truly effective predictive maintenance solution, built for the realities of the agri-food sector, can turn skeptics into champions.

1. “We’ve tried vibration analysis before — it didn’t work.”

This is a common lament heard from maintenance professionals. Many early attempts at predictive maintenance, particularly those focused solely on manual vibration analysis, often yielded poor ROI. The process was cumbersome, requiring highly skilled technicians for data collection and interpretation, and frequently lacked consistent follow-through or actionable insights. Data might have been collected, but its translation into a clear plan of action was often missing or delayed.

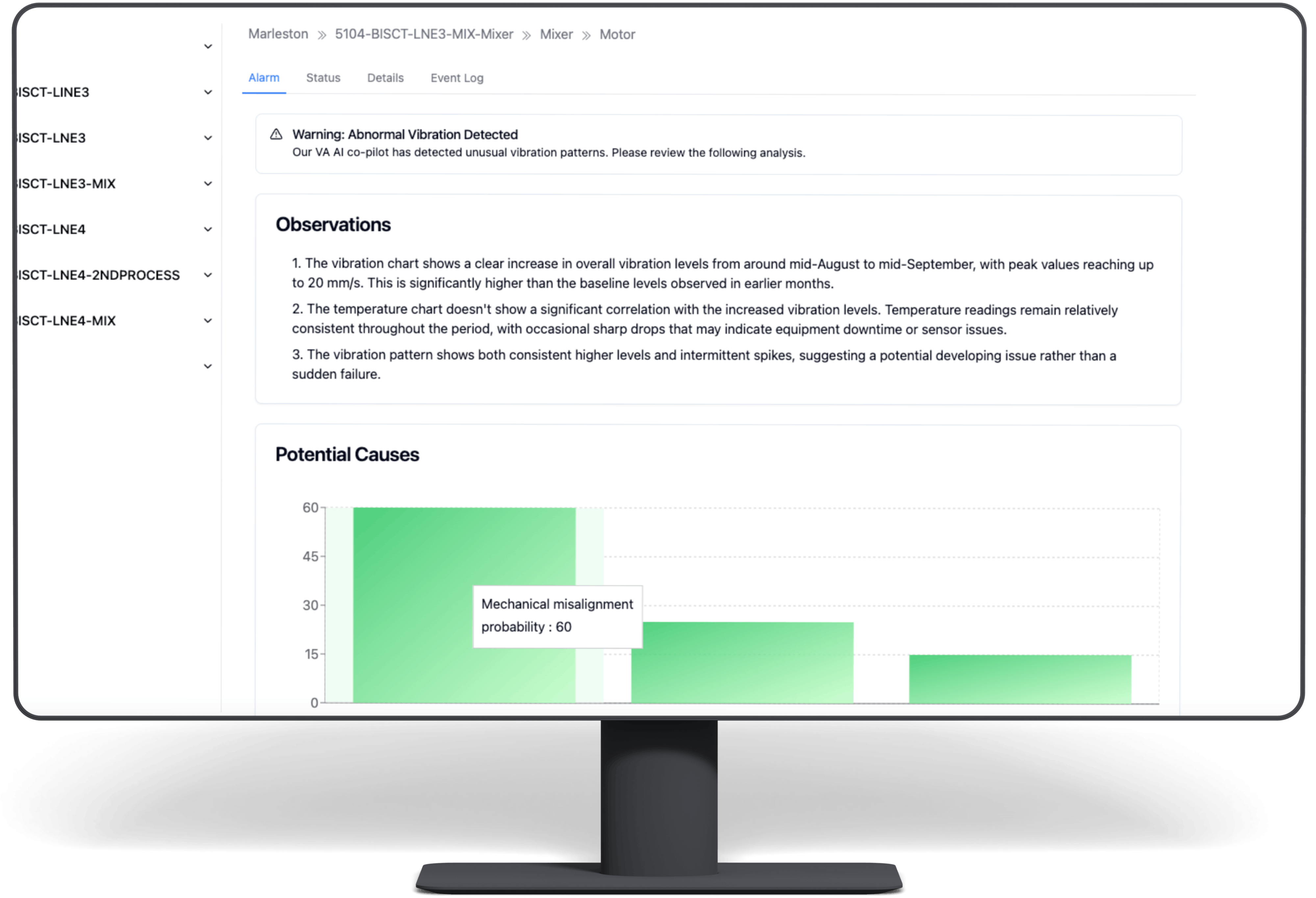

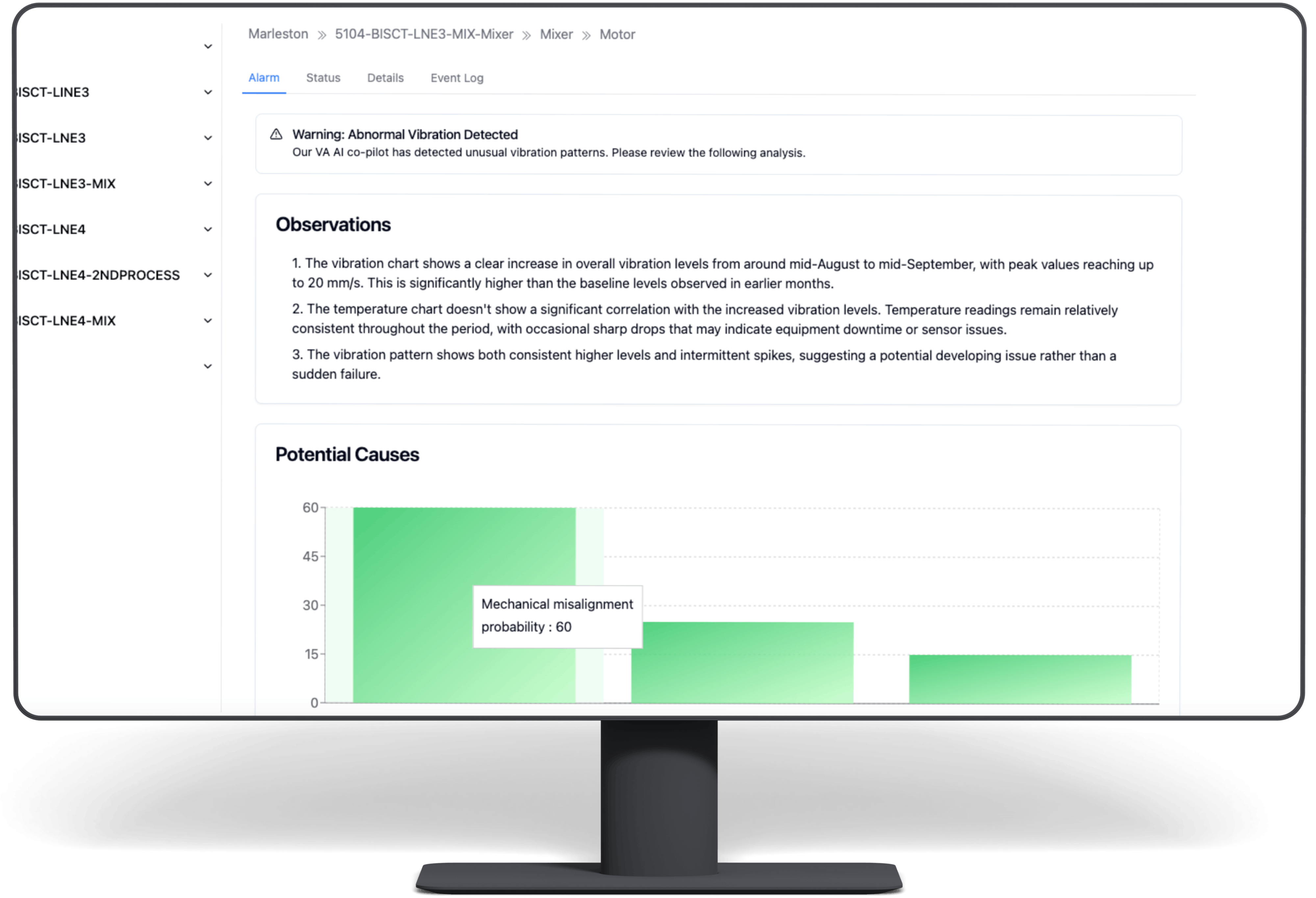

Solution: Modern machine condition monitoring with AI moves far beyond sporadic, manual vibration analysis. Platforms like Factory AI employ always-on monitoring with sophisticated, wireless condition monitoring sensors that continuously collect data on vibration, temperature, acoustics, and other critical parameters. The crucial difference lies in the automated insights generated by advanced AI and machine learning algorithms. This means no vibration analysis expertise is required from your in-house team. The system interprets complex data patterns, identifies anomalies, and provides clear, actionable alerts, drastically reducing the need for specialist intervention. Furthermore, such systems facilitate closed-loop ROI tracking, demonstrating the tangible value of every prevented breakdown. This shift from a manual, expertise-dependent approach to an automated, AI-driven one is fundamental to success. Our approach to automated insights significantly reduces the historical pain points associated with traditional vibration analysis. You can explore how modern condition monitoring systems work in more detail on the Allied Reliability Blog.

2. “We don’t have budget for this right now.”

Budget constraints are a perpetual challenge in maintenance departments, where new technology is often seen as an additive cost rather than a strategic investment. This is particularly true if the value proposition isn't immediately clear or if the cost is perceived as solely an IT expense.

Solution: This objection can be preempted by positioning predictive maintenance software not as an expense, but as a powerful cost-avoidance tool. Consider the actual cost of a single major equipment failure – often upwards of £100,000 for large machinery in a busy production line, encompassing repair, lost production, potential product write-offs, and compliance fines. Predictive maintenance proactively prevents these catastrophic events. Factory AI, for example, often pays for itself in 6 months by averting just a few such failures. This rapid ROI of predictive maintenance is a killer differentiator. We focus on business value, not just technology. Furthermore, explore low-risk predictive maintenance pilot program options or ROI-based justification models, demonstrating tangible savings before a full-scale rollout. It’s about shifting the perception from "spending money" to "saving significantly more money" and highlighting the opportunity cost of not adopting modern solutions. The Marshall Institute Blog offers valuable insights into justifying maintenance investments.

3. “We don’t have the people to manage another system.”

Maintenance teams are frequently stretched thin, dealing with a constant stream of reactive issues and planned activities. The prospect of adopting yet another complex software system can feel overwhelming, threatening to add to an already heavy workload. This objection is about perceived complexity and an already strained workforce.

Solution: A key strength of modern predictive maintenance tools is their ability to reduce workload, not increase it. Factory AI, for instance, provides automated alerts and prescriptive recommendations, meaning fewer manual inspections and reactive emergency repairs. The system is designed for the team on the tools, with intuitive interfaces that simplify data interpretation and task management. This means your team receives precise, actionable insights, enabling them to work smarter, not harder. Our solution reduces the amount of time spent on routine checks and troubleshooting, freeing up your skilled technicians for more strategic tasks. It integrates seamlessly into existing workflows, ensuring that maintenance managers and technicians receive precise, actionable insights. This helps to alleviate the burden on overstretched teams and ensures that the introduction of a new system simplifies, rather than complicates, daily operations. We understand that time is precious, and our goal is to empower your team, not burden them.

4. “We already have a CMMS — why do we need this?”

There's a common misconception that a CMMS for manufacturing provides predictive capabilities. While a CMMS (Computerised Maintenance Management System) is excellent for managing work history, scheduling, and asset data, it is not inherently a predictive tool. It often tells you what has happened or what is scheduled, not what will happen.

Solution: Clarify that predictive maintenance software, like Factory AI, complements a CMMS rather than replaces it. A CMMS tracks what has happened and what is scheduled; predictive maintenance tells you what is about to happen, enabling intervention before failures occur. Factory AI provides the crucial "when and why" of potential failures, feeding these insights into your CMMS to automatically generate optimised work orders based on real-time asset condition. This transforms your CMMS from a record-keeping system into a dynamic, proactive maintenance planning and scheduling software, significantly enhancing overall asset reliability. Factory AI isn't just PdM; we are evolving into a full reliability platform, offering integrated CMMS capabilities, maintenance task management, and intelligent scheduling. This positions us as a one-stop solution for optimising your entire maintenance operation. Think of your CMMS as the brain for managing maintenance tasks, and predictive maintenance as the sensory nervous system providing critical, early warnings. Maintenance World offers further insights into the synergy between these systems.

5. “Our equipment is too old or too simple for AI.”

Legacy manufacturing plants often assume that advanced AI solutions are only compatible with new, "smart" assets. This is a significant misconception that can prevent older facilities, common in the agri-food sector, from embracing transformative technology. They might believe their basic motors or pumps lack the necessary digital interfaces for machine condition monitoring with AI.

Solution: This objection highlights a crucial area where modern predictive maintenance truly excels. Factory AI is specifically designed to work with virtually any rotating machinery, regardless of age or existing connectivity. This includes common assets found in agri-food plants like motors, pumps, fans, and conveyors – all critical components susceptible to wear and tear. Our solution uses advanced, non-invasive predictive maintenance equipment and sensors that capture machine condition data, and its AI algorithms can build reliable predictive models even for assets that lack built-in smart capabilities. It's not about the age of the machine, but the intelligence of the monitoring system. We help bring "smart" capabilities to "dumb" assets. The adaptability of our system means you don't need to overhaul your existing machinery to reap the benefits of advanced analytics. The Machine Design Magazine provides excellent resources on the capabilities of modern sensors and monitoring.

6. “IT/security won’t allow it.”

Cybersecurity and IT integration concerns are significant blockers, especially for cloud-based or wirelessly connected systems in sensitive manufacturing environments. Data security is paramount, particularly in industries with strict compliance requirements like food and beverage, where operational technology (OT) security is a growing concern.

Solution: Be proactive and transparent about your IT architecture. Solutions like Factory AI offer modem-based options, which means they typically do not require direct integration with your plant's existing Wi-Fi or IT network. This significantly mitigates security concerns, as data is transmitted securely and independently. We understand the stringent demands of maintenance in high hygiene environments and have built our system with robust secure encryption protocols. We can readily provide references from other approved sites that have successfully navigated IT and security reviews. This highlights that cutting-edge technology can be deployed without compromising your robust cybersecurity posture, giving your IT team peace of mind. Our system is designed for maximum security with minimal IT footprint.

7. “What happens after the pilot — are we locked in?”

Fear of long-term commitments, especially after an initial trial, is a common concern.

Manufacturers want flexibility and predictability, and they want to know that an initial investment won't lead to an unavoidable, costly long-term obligation if the solution doesn't meet expectations.

Solution: Transparency is key here. A reputable best predictive maintenance software provider should offer no lock-in contracts and clear, predictable pricing. Factory AI, for instance, offers a straightforward sensor + software bundled in one subscription model, typically around £500 per asset per year. This flat-fee approach removes hidden costs and allows for optional, scalable expansion based on your specific needs and the proven success of the pilot. Furthermore, any learnings and data collected during a predictive maintenance pilot program should be transferable and retained by the client, ensuring value even if a full rollout doesn't immediately proceed. We offer predictable pricing and a transparent approach that lets you scale at your own pace, ensuring you're never locked into something you don't want.

8. “It sounds good, but we don’t think we have that much downtime to justify it.”

Organisations often underestimate the true cost of unplanned downtime or have normalised chronic minor issues, viewing them as simply "the way things are." They might not track the full spectrum of costs associated with even small, frequent stoppages, or they might compare predictive maintenance only against catastrophic failures, missing the cumulative impact of smaller disruptions.

Solution: Educate on the hidden costs of unplanned failures. Use industry benchmarks and simple downtime cost calculators to help them quantify their current losses. The true ROI of predictive maintenance extends beyond preventing catastrophic breakdowns; it includes reductions in energy consumption, extended asset lifespan, optimised maintenance schedules, and a significant decrease in product waste, all of which contribute to a healthy bottom line. Predictive maintenance case studies, particularly from the food and beverage industry (e.g., predictive maintenance for dairy plants), can powerfully illustrate how what seems like minor disruptions accumulate into substantial financial drains. Even seemingly minor events like product being held in a conveyor due to a sensor fault can escalate to spoilage or significant waste. We help reveal these hidden costs and demonstrate how a proactive approach saves money in unexpected ways. The Reliable Plant publication regularly features articles on quantifying downtime costs.

9. “We already do preventive maintenance, and it's working fine.”

This objection often stems from conflating time-based preventive maintenance software with true condition-based predictive maintenance. While PM is a step up from reactive maintenance, it has inherent limitations. It’s based on averages and schedules, not the actual condition of a specific machine, leading to either premature interventions or unforeseen failures.

Solution: Educate on the fundamental difference: predictive maintenance vs preventive maintenance. Time-based PM relies on schedules (e.g., changing a bearing every six months), which often means either replacing components too early (wasteful) or too late (leading to failure). Predictive maintenance, through machine condition monitoring with AI, leverages real-time vibration monitoring and other data to identify the actual condition of an asset. This allows maintenance to be performed precisely when needed, extending asset life, reducing unnecessary parts replacement, and optimising technician time. It's about being proactive and intelligent, not just scheduled. Our solution ensures that maintenance is done just in time, reducing both over-maintenance and under-maintenance. As Reliability Solutions Blog highlights, "Predictive maintenance moves away from fixed schedules to a dynamic, data-driven approach that truly optimises asset performance." This approach also significantly impacts your ability to integrate HACCP and maintenance software, ensuring that maintenance activities do not compromise food safety standards.

10. “It won’t work here — our site is unique.”

Every factory believes its operations, equipment, and culture are unique, making them resistant to "off-the-shelf" solutions. This can be particularly prevalent in the agri-food sector due to diverse production processes, specialized machinery, and stringent regulatory environments.

Solution: Acknowledge and respect their uniqueness. While every site has its peculiarities, the underlying physics of machine failure are universal. Solutions like Factory AI are built with adaptability in mind, with proven track records across diverse environments within the agri-food sector – from predictive maintenance for dairy plants with their specific hygiene demands to seafood processing and baked goods manufacturers. Our system has been successfully deployed in various challenging environments, adapting to different asset types and operational schedules. We offer a tailored rollout plan that addresses their specific challenges and showcases how the solution adapts to their particular asset types, operational schedules, and maintenance in high hygiene environments. This demonstrates an understanding of their concerns while highlighting the broad applicability of the technology. Our solution is designed to be highly configurable and can be seamlessly integrated into your specific operational context, ensuring that its benefits are fully realised regardless of your plant's unique characteristics.

The Factory AI Advantage: Your Partner in Proactive Reliability

Factory AI isn't just another predictive maintenance software; it's a comprehensive reliability platform built specifically for the demanding world of manufacturing, with a keen understanding of the agri-food sector's unique needs. Our solution directly addresses these common objections by offering a powerful, yet simple, approach:

- "Predictive Maintenance That Pays for Itself in 6 Months": We focus on tangible business value, demonstrating rapid ROI through prevented downtime and optimised maintenance spend. This isn't just about technology; it's about significant financial gains that speak directly to decision-makers. Our track record shows a clear and swift return on your investment, making the business case for adoption undeniably strong.

- "Built for the Agri-Food Industry": Our specialisation builds trust. Emphasising suitability for cold rooms, high hygiene areas, and the specific equipment found in seafood, dairy, baked goods, and FMCG plants ensures our solution is perfectly suited to your operational realities. This specialisation not only builds trust but also means our insights are highly relevant and actionable for your specific challenges. For instance, ensuring continuous operation in a dairy plant is critical for preventing spoilage and maintaining stringent HACCP and maintenance software compliance.

- "Works Without Wi-Fi or IT Integration": A huge blocker is IT. Our modem-based or offline-capable setups bypass common IT roadblocks, offering secure, independent data transmission. This ensures rapid deployment and minimal disruption to your existing infrastructure, a huge win for conservative or bandwidth-poor plants. You don't need to worry about complex network configurations or cybersecurity vulnerabilities within your plant's core network.

- "No Vibration Analysis Expertise Required": Many teams have sensors but lack interpretation. Our AI-powered platform automates complex data interpretation, delivering clear, actionable insights directly to your team on the tools. This empowers your existing workforce without requiring additional specialist hires or costly external consultants. Factory AI's automatic fault detection removes reliance on specialists, providing a clear usability edge.

- "Sensor-Agnostic – Use the Hardware You Already Have": We're not pushing proprietary sensors. This flexibility reduces initial investment and allows you to leverage any existing condition monitoring systems or hardware you may have already invested in. This makes Factory AI flexible, lower cost, and easier to trial and implement across your diverse asset base.

- "From Install to Insight in Under 30 Minutes per Asset": Speed of deployment is a major advantage. Our system is designed for quick, hassle-free installation, meaning you can start gaining insights and preventing failures almost immediately, with minimal disruption to your daily operations. This rapid deployment capability is a significant differentiator, allowing you to quickly realise value.

- "Sensor + Software Bundled in One Subscription": Simplicity wins. We offer a transparent, flat-fee model, typically around £500 per asset/year, simplifying budgeting and avoiding unexpected costs. This clear, predictable pricing appeals directly to busy plant managers and budget holders, removing financial uncertainty.

- "Designed for the Team on the Tools": Many PdM tools are built for analysts or corporate; we're built for the person maintaining the machine. Our user-friendly interface and practical insights are crafted for maintenance technicians and managers who are on the plant floor every day. This empathy ensures high adoption rates and practical utility.

- "Built by Engineers Who’ve Worked on the Plant Floor": Authenticity matters. Our team understands the realities of industrial environments because we've lived them. This authentic perspective informs every aspect of our solution, ensuring it's robust, reliable, and truly helpful – not a Silicon Valley solution trying to 'disrupt' without understanding.

- "More Than Predictive – A Full Reliability Platform": Factory AI isn’t just PdM. We now offer integrated CMMS capabilities, maintenance task management, scheduling, and AI-assisted insights. This positions us as a one-stop solution for optimising your entire maintenance operation, providing a holistic view of your asset health and maintenance workflows. Our platform streamlines everything from initial fault detection to work order generation and completion.

Real-World Impact: Predictive Maintenance Case Studies in Agri-Food

Consider a large bakery, constantly battling unexpected downtime on its critical mixers due to bearing failures. Traditional preventive maintenance schedules often led to premature bearing replacements or, conversely, catastrophic failures just before a scheduled service. By implementing Factory AI, with its wireless condition monitoring sensors, the plant could monitor real-time vibration monitoring and temperature. The AI detected subtle anomalies in a mixer's motor weeks before failure, allowing maintenance to schedule a replacement during a planned shutdown, averting a costly disruption that would have impacted several production lines and led to significant product waste. The ROI was clear within months, demonstrating how predictive maintenance for FMCG is a game-changer.

Another compelling example is a dairy plant using Factory AI to monitor its pasteurisation pumps. Given the critical hygiene environment and the cost of product spoilage, proactive maintenance is crucial. The system's ability to operate without heavy IT integration was a major benefit, addressing initial security concerns from their IT department. When the system flagged a developing issue with a pump's seals, the team was able to address it promptly, preventing a potential contamination event and maintaining continuous, compliant operations. This not only saved the cost of a catastrophic failure but also ensured adherence to stringent HACCP and maintenance software standards. This demonstrates the critical role of predictive maintenance for dairy plants.

These are not isolated incidents; they represent a fundamental shift from reactive chaos to proactive control across various segments of the agri-food industry. The benefits extend beyond simply avoiding downtime, encompassing improved safety, better resource allocation, and a deeper understanding of asset health monitoring. For more insights into the practical application and success stories of predictive maintenance, the Predict Industrial Reliability Blog offers a wealth of real-world examples.

Conclusion: Take Control of Your Reliability

The common objections to predictive maintenance are understandable, but they no longer reflect the reality of modern, AI-powered solutions. The time for reactive or purely preventive maintenance is over, especially in the competitive and high-stakes world of agri-food manufacturing. By embracing advanced asset health monitoring, you can unlock significant cost savings, increase uptime, enhance safety, and extend the life of your critical equipment. The shift to a proactive, data-driven approach is not just an upgrade; it's a strategic imperative for long-term success and resilience.

Don't let outdated perceptions or perceived complexities hold your plant back. It's time to experience the future of maintenance. Factory AI offers not just technology, but a partnership built on understanding the realities of your plant floor and delivering tangible business value.

Ready to see how Factory AI can transform your operations and deliver rapid ROI?

Book a demo with us today and let us show you how predictive maintenance that pays for itself can revolutionise your agri-food plant's reliability, turning your objections into opportunities.