The Ultimate Playbook: How to Choose the Best Predictive Maintenance Software for Your Factory in 2025

Aug 14, 2025

best predictive maintenance software for factories

You're here because the old way of doing things isn't working anymore. The endless cycle of reactive maintenance—the frantic calls, the costly emergency repairs, the unexpected downtime that ripples through your entire production schedule—is a drain on resources and a barrier to growth. You know there’s a better way. You’ve heard the term "predictive maintenance" (PdM), and you understand its promise: to fix equipment before it fails.

But a quick search for the "best predictive maintenance software for factories" likely left you with more questions than answers. You've seen endless listicles, sponsored reviews, and jargon-filled websites that all claim to be the ultimate solution.

This isn't another one of those lists.

This is a strategic playbook. The search intent for this topic is investigational and commercial, meaning you're past the "what is it?" stage and are now deep into the "how do we make the right choice and succeed with it?" phase. This guide is designed for you: the maintenance manager, the operations director, the plant engineer who needs to make a sound, data-driven decision that will deliver a real return on investment.

We'll walk you through the entire process, from laying the essential groundwork in your facility to evaluating different types of software, launching a successful pilot, and scaling a proactive maintenance culture across your entire operation. Let's build a smarter, more reliable factory together.

Before You Even Look at Software: The PdM Groundwork

Jumping straight into software demos without proper preparation is like trying to build a house without a foundation. The most advanced AI in the world can't help you if your internal processes, data, and goals aren't aligned. Success starts here.

Step 1: Define Your "Why" with Crystal-Clear Goals

What business problem are you trying to solve? "Implementing predictive maintenance" is a task, not a goal. A strong goal is specific, measurable, achievable, relevant, and time-bound (SMART).

- Weak Goal: "We want to reduce downtime."

- Strong Goal: "We will reduce unplanned downtime on our CNC milling line by 30% within 12 months of PdM implementation, saving an estimated $250,000 in lost production."

- Weak Goal: "We want to improve maintenance efficiency."

- Strong Goal: "We will decrease emergency maintenance work orders by 50% and increase the planned maintenance percentage from 40% to 80% within the first year."

Sit down with stakeholders from operations, finance, and management. Quantify the cost of your current maintenance strategy. How much does an hour of downtime on your most critical line actually cost? What are you spending on overtime for emergency repairs? This data will not only build your business case but will also become the benchmark against which you measure the success of your new software.

Step 2: Conduct an Asset Criticality Analysis

You cannot and should not monitor every single piece of equipment with advanced PdM technology. The key is to focus your resources where they will have the most impact. An Asset Criticality Analysis (ACA) helps you rank your equipment based on its importance to your operation.

Consider factors like:

- Production Impact: What happens if this asset fails? Does it stop a single process or the entire production line?

- Safety & Environmental Impact: Could a failure lead to a safety incident or an environmental release?

- Cost of Failure: What is the combined cost of repair parts, labor, and lost production?

- Repair Time (MTTR): How long does it take to get this asset back online? Are spare parts readily available?

A common method for this is a Failure Mode and Effects Analysis (FMEA). This structured approach helps you identify potential failure modes for an asset, and then assess the severity, occurrence, and detection of each mode to calculate a Risk Priority Number (RPN). Assets with the highest RPN are your prime candidates for your initial PdM program. According to industry best practices highlighted by sources like Reliabilityweb, a robust FMEA is a cornerstone of any world-class maintenance program.

Step 3: Perform a Brutally Honest Data Readiness Assessment

Predictive maintenance runs on data. It is the fuel for the AI and machine learning algorithms that power the software. If your data is sparse, inaccurate, or inaccessible, your PdM initiative will stall.

Assess your data maturity across these key areas:

- Sensor Data: Do you have sensors (vibration, thermal, acoustic, oil analysis, etc.) on your critical assets? Are they collecting data consistently? What is the frequency and granularity of this data? If not, a sensorization strategy will be your first major investment.

- CMMS/EAM Data: How clean is your maintenance history? Do you have detailed records of past failures, repairs performed, and parts used? An AI predictive maintenance model learns from this historical data. Incomplete or inconsistent work order descriptions ("fixed machine") are useless. You need specifics ("Replaced 6208-2Z bearing on main drive motor due to excessive spalling detected during vibration analysis").

- Operational Data: Can you access data from your SCADA, MES, or historian systems? Correlating operational data (e.g., load, speed, pressure, throughput) with sensor data provides crucial context for the AI models. A sudden spike in vibration means one thing when a machine is under heavy load, and something entirely different when it's idle.

If you identify significant gaps, your initial focus should be on improving data collection and hygiene. This might mean a sensor pilot project or a major cleanup of your CMMS data before you even consider a full PdM software rollout.

Deconstructing Predictive Maintenance Software: The Core Components

Now that you've laid the groundwork, you can start evaluating software with a clear understanding of what you need. A comprehensive PdM solution is more than just a fancy dashboard; it's an ecosystem of interconnected components.

Component 1: Data Ingestion and Integration

The software must be able to connect to all your data sources seamlessly. This is non-negotiable. Look for a platform with a flexible and robust integration engine.

- IIoT Sensor Connectivity: Does it support common industrial protocols like MQTT, OPC-UA, and Modbus? Can it connect directly to gateways from major sensor providers?

- CMMS/EAM Integration: The system must have a two-way sync with your Computerized Maintenance Management System. The PdM software needs to pull historical work order data for model training, and it needs to push alerts and automatically generate new work orders when it predicts a failure. A standalone PdM system that forces technicians to manually transfer data between systems creates friction and kills adoption. Powerful integrations are the key to a unified maintenance workflow.

- Enterprise System Connectivity: Can it connect to your ERP (for parts inventory and cost analysis) and MES/SCADA systems (for operational context)? The more data sources you can unify, the more accurate and insightful your predictions will be.

Component 2: The Analytics Engine (The "Brain")

This is where the magic happens. The analytics engine takes the raw data and transforms it into actionable insights. Don't be dazzled by buzzwords like "AI" and "Machine Learning." Dig deeper to understand how it works.

- Anomaly Detection: This is the first level of analysis. The system establishes a baseline of normal operating behavior for an asset and flags any deviation from that baseline.

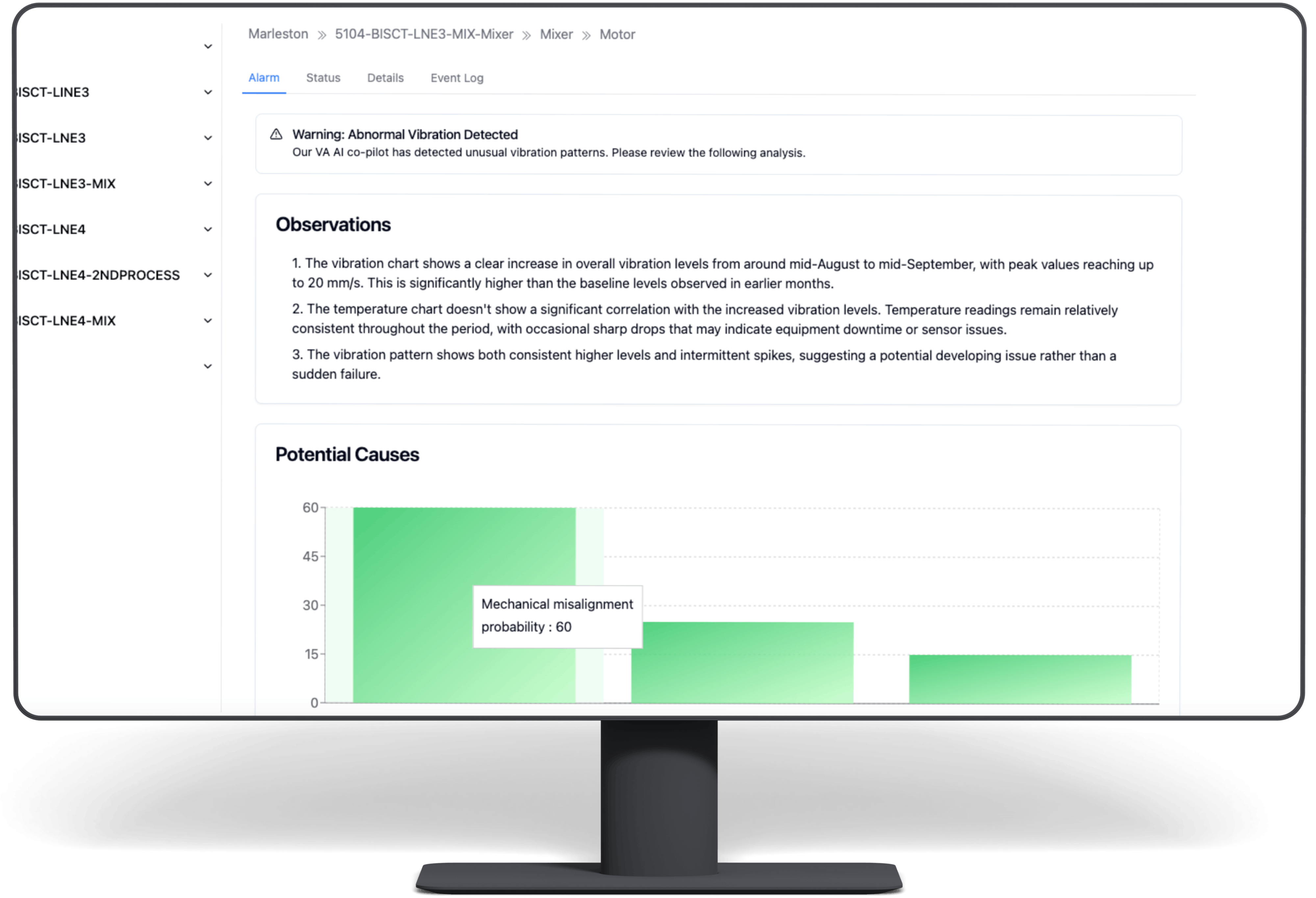

- Diagnostic and Root Cause Analysis: When an anomaly is detected, can the software help diagnose the potential cause? For example, specific vibration frequency patterns can distinguish between bearing wear, misalignment, or imbalance.

- Remaining Useful Life (RUL) Estimation: This is the holy grail of PdM. RUL models predict the time remaining until an asset is likely to fail, allowing you to schedule maintenance at the optimal moment—not too early (wasting component life) and not too late (risking failure). Ask vendors about the accuracy of their RUL models and what data is required to generate them.

- Model Transparency ("Explainable AI"): Can the vendor explain why the model is predicting a failure? A "black box" system that just says "fix this motor" is less trustworthy and harder to troubleshoot than a system that says "fix this motor because its vibration signature at 2x the running speed has increased by 40% and its temperature is 15°C above its historical average under similar loads, indicating advanced bearing wear."

Component 3: The User Experience (Actionable Insights, Not Data Overload)

The most brilliant algorithm is useless if its output is confusing or ignored. The software's interface must be designed for the end-user: the maintenance technician, the reliability engineer, and the plant manager.

- Intuitive Dashboards: Can you see the health of all your critical assets at a glance? Is it easy to drill down from a plant-level overview to a specific sensor on a single component?

- Configurable Alerts: You need intelligent, multi-level alerting. A minor anomaly might trigger an email to the reliability engineer for investigation, while a critical RUL prediction should automatically generate a high-priority work order software ticket and send a mobile alert to the on-duty supervisor.

- Mobile Accessibility: Maintenance happens on the factory floor, not behind a desk. A robust mobile app is essential for technicians to view alerts, access asset history, and close out work orders in the field.

The 2025 Buyer's Guide: Evaluating Categories of PdM Software

The PdM software market is diverse. Solutions generally fall into three main categories. Understanding these categories will help you narrow your search to the vendors that are the right fit for your factory's scale, budget, and technical maturity.

Category 1: Enterprise Asset Performance Management (APM) / IIoT Platforms

- Who they are: These are the massive, all-encompassing platforms from industrial giants like Siemens (MindSphere), GE (Predix), and AVEVA (PI System).

- Pros: Extremely powerful and scalable, designed for large, multi-site enterprises. They offer a vast suite of tools covering everything from PdM to energy management and production optimization. They often include advanced features like digital twin capabilities.

- Cons: Can be incredibly complex and expensive to implement and maintain. They often require a dedicated team of data scientists and IT specialists. The implementation timeline can be very long.

- Best for: Large, mature organizations with significant budgets, complex operations, and in-house data science expertise who are undertaking a full-scale digital transformation.

Category 2: AI-Powered CMMS with Integrated PdM Modules

- Who they are: This is a rapidly growing category. These are modern CMMS platforms that have built-in AI/ML capabilities and IIoT connectivity. Instead of being a separate system, PdM is a native feature of the core maintenance management workflow.

- Pros: Offers a unified, single-pane-of-glass experience. The tight integration between asset management, work orders, inventory, and predictive analytics eliminates data silos and simplifies workflows. They are generally faster to implement and more user-friendly for maintenance teams than enterprise APM platforms.

- Cons: May not have the sheer breadth of features of a dedicated enterprise APM suite. The quality and depth of the AI capabilities can vary significantly between vendors.

- Best for: Small to large factories that want a practical, integrated solution to bring predictive capabilities directly into their daily maintenance operations. This approach provides the fastest path to value for most manufacturing facilities. A modern CMMS software is the operational backbone for turning predictive insights into completed work.

Category 3: Niche, Condition-Specific Solutions

- Who they are: These are specialized tools that focus on one specific type of condition monitoring, such as vibration analysis (e.g., Augury, Fluke), thermal imaging analysis, or oil analysis.

- Pros: Deep expertise in their specific domain. They often provide best-in-class hardware and analytical models for their niche. Can be a great way to start a PdM journey by focusing on one critical failure mode.

- Cons: They create data silos. You might end up with one system for vibration, another for thermography, and a third for oil analysis, none of which talk to each other or your CMMS. This creates a fragmented view of asset health.

- Best for: Factories looking to solve a very specific, known problem (e.g., "bearing failures are our #1 cause of downtime") or for augmenting a broader platform with deep, specialized analytical capabilities.

Your Evaluation Checklist

When you start demoing software, have a scorecard ready. Score each potential vendor on these critical criteria:

- Ease of Integration: How easily does it connect to your existing CMMS, sensors, and enterprise systems?

- Scalability: Can the solution grow with you from a 10-asset pilot to a 1,000-asset factory-wide deployment?

- Model Performance & Transparency: How accurate are their predictive models? Can they explain how their algorithms work?

- User Experience: Is it intuitive for your technicians and engineers? Is the mobile app fully functional?

- Domain Expertise: Does the vendor understand manufacturing and your specific industry? Do they have case studies from companies like yours?

- Support & Training: What level of support is included during and after implementation? Do they offer comprehensive training for your team?

- Total Cost of Ownership (TCO): Look beyond the initial license fee. Factor in implementation costs, hardware (sensors), training, and ongoing subscription fees.

The Implementation Playbook: From Pilot to Full-Scale Rollout

Choosing the software is only half the battle. A structured, phased implementation is crucial for success and for demonstrating ROI to management.

Phase 1: The Strategic Pilot Program (3-6 Months)

Don't try to boil the ocean. Start with a focused pilot project on a single production line or a small group of 5-10 critical assets you identified in your ACA.

- Choose the Right Assets: Select assets that have a well-documented history of failures and where a successful outcome will be highly visible and impactful.

- Define Success Metrics: Revisit the SMART goals you set. For the pilot, this might be "Detect at least 2 incipient failures on our primary extruder line within 3 months, avoiding an estimated 12 hours of unplanned downtime."

- Onboard a Champion Team: Involve your best technicians, a reliability engineer, and an IT liaison. These will be your super-users and internal champions.

- Validate the Model: Work closely with the software vendor to train the AI models on your historical data and validate their initial findings against the knowledge of your experienced technicians.

Phase 2: Integrate, Train, and Refine (Months 6-12)

Once the pilot has proven its value, it's time to deepen the integration and expand the user base.

- Deepen Integrations: Solidify the two-way sync with your CMMS. Automate the process of converting a PdM alert into a planned work order.

- Train the Entire Team: This is a critical change management step. Train all maintenance personnel on how to use the new system and, more importantly, how to shift their mindset from "find and fix" to "predict and prevent." The goal is to build trust in the technology.

- Refine Workflows: How do you prioritize a PdM-generated work order versus a standard PM or a user-submitted request? Update your standard operating procedures (SOPs) to incorporate the new data source.

Phase 3: Scale and Optimize (Year 2 and Beyond)

With a successful pilot and a trained team, you can now develop a roadmap for a factory-wide rollout.

- Phased Expansion: Add new assets to the system in logical groups (e.g., by area, by equipment type).

- Continuous Improvement: Use the data from the PdM system to optimize your entire maintenance strategy. You might find that you can extend PM intervals on some assets while increasing inspection frequency on others.

- Measure and Report: Continuously track your initial KPIs (downtime, MRO costs, planned vs. unplanned work) and report the ROI to management to secure ongoing support and investment. For more information on setting up effective maintenance procedures, check out our guide on PM procedures.

Beyond Prediction: The Future is Prescriptive

As you master predictive maintenance, the next frontier is already here: prescriptive maintenance. This is the evolution from simply predicting a failure to recommending a specific course of action.

A predictive system says: "The bearing on Motor 7B will fail in approximately 200 operating hours."

A prescriptive system says: "The bearing on Motor 7B will fail in approximately 200 operating hours. The required SKF 6209-2RS1 bearing is in stock (3 units available). Given the current production schedule, the optimal time to perform the 90-minute replacement procedure is during the scheduled changeover on Tuesday at 2:00 AM. We recommend creating a work order assigned to Technician Jane Doe, who has the highest success rate for this task."

This level of recommendation, often powered by advanced AI and digital twins, represents the pinnacle of maintenance optimization. Choosing a software platform with a clear roadmap toward prescriptive maintenance ensures your investment will continue to pay dividends for years to come. The NIST is actively involved in setting standards for these digital twin and smart manufacturing technologies, highlighting their growing importance.

Common Pitfalls and How to Avoid Them

Many PdM initiatives fail not because of the technology, but because of preventable mistakes in strategy and execution.

- Pitfall 1: The Data Quality Trap ("Garbage In, Garbage Out").

- How to Avoid: Don't skip the data readiness assessment. Invest time in cleaning your CMMS data and developing a solid sensor strategy before you sign a contract.

- Pitfall 2: The "Set It and Forget It" Mindset.

- How to Avoid: A PdM system is not a magic box. It requires continuous monitoring, model refinement, and human expertise to interpret its findings. Treat it as a powerful tool that augments, rather than replaces, your skilled technicians.

- Pitfall 3: Ignoring the Human Element.

- How to Avoid: Change management is paramount. Involve your team from day one. Explain the "why" behind the change. Frame the new software not as a threat, but as a tool to make their jobs safer, less stressful, and more impactful.

Conclusion: The "Best" Software is the Right Software for You

There is no single "best predictive maintenance software for factories." The best solution is the one that aligns with your operational maturity, your specific goals, your technical infrastructure, and your people.

By following this playbook, you can move beyond generic lists and conduct a truly strategic evaluation. Start by building a solid foundation: define your goals, understand your assets, and assess your data. Then, deconstruct the software to understand its core components and evaluate vendors based on a clear set of criteria. Finally, implement your chosen solution through a phased, strategic approach, starting with a pilot and scaling with intention.

The transition from reactive to predictive maintenance is a journey, not a destination. But by choosing the right partner and the right technology, you can build a more resilient, efficient, and profitable manufacturing operation for years to come.