The Top CMMS Solutions for Small Manufacturers in 2025

Aug 9, 2025

CMMS

Why choosing the right CMMS in 2025 matters more than ever

If you are running a small manufacturing operation in 2025, chances are you are already facing the same challenges your peers talk about on plant floors and in industry forums. Machines are pushed to their limits, maintenance teams are running lean, and the margin for error has never been smaller. One unplanned breakdown can stop production for hours or even days, costing not just lost output but also damaged customer trust.

This is why choosing the right Computerised Maintenance Management System (CMMS) is no longer a nice-to-have for small manufacturers. It is a competitive advantage. The right CMMS is not just a digital filing cabinet for work orders. It can become the heartbeat of your maintenance operation — tracking every asset, predicting problems before they happen, and giving your team the clarity to act fast.

In this article, we are going to explore the ten most powerful CMMS options for small manufacturers in 2025, with a deep dive into how each one stacks up for agility, cost-effectiveness, and impact. At the top of that list is Factory AI’s Prevent CMMS, a platform built specifically for small and mid-sized plants that want predictive maintenance and asset management in one streamlined package.

The growing pressure on small manufacturers

Small manufacturers, particularly in the agri-food sector, are under unique pressures in 2025. Input costs remain high, energy prices fluctuate, and customers expect faster delivery without compromising quality. Meanwhile, skilled maintenance labour is harder to find than ever.

When a machine stops, it is not just the maintenance team that feels the pressure. Operators, supervisors, planners, and even finance teams are affected. Each hour of downtime can mean thousands of dollars in lost revenue, missed delivery windows, and costly overtime to catch up.

The traditional approach — running reactive maintenance supported by spreadsheets or basic work order tools — is falling behind the pace of modern production. Teams cannot rely solely on paper trails, tribal knowledge, or quarterly service schedules. They need a connected, centralised system that captures every task, keeps the whole team aligned, and integrates predictive capabilities that can cut breakdowns before they happen.

Why many CMMS systems fail small manufacturers

The CMMS market is crowded, but not all solutions are designed for the realities of a small manufacturing site. Here are some of the common pitfalls we see when small plants try to adopt systems that were not built for them:

- Overly complex implementations

Enterprise CMMS platforms can take months to configure and often require IT resources a small site does not have. By the time the system is live, user enthusiasm has faded and many teams fall back to old habits. - Poor adoption on the plant floor

If your CMMS is not intuitive, frontline maintenance teams will resist using it. Every extra click or confusing menu slows them down and makes it more likely that work orders or asset histories will be incomplete. - High ongoing costs

Many CMMS vendors price their platforms for global corporations. Subscription costs, integration fees, and add-on modules can make them hard to justify for a small plant. - No predictive capability

Most CMMS platforms are purely reactive. They log jobs, but they do not help prevent them. Without predictive analytics, maintenance teams are left chasing problems instead of getting ahead of them. - Poor fit for specific industries

A generic CMMS may ignore the unique needs of agri-food manufacturing — such as perishable goods, hygiene compliance, seasonal production surges, and asset types that do not appear in other industries.

The shift toward predictive and preventive in one platform

A trend that has gained serious traction in 2025 is the merging of CMMS capabilities with predictive maintenance technology. For small manufacturers, this is a game changer. Instead of juggling two systems — one for asset management and one for predictive alerts — they can have a single platform that tells them what to do and when to do it.

By embedding predictive insights into the work order process, maintenance teams can move from a purely time-based or reactive approach to a precision-based approach. That means fewer unnecessary PM tasks, fewer breakdowns, and more targeted maintenance efforts.

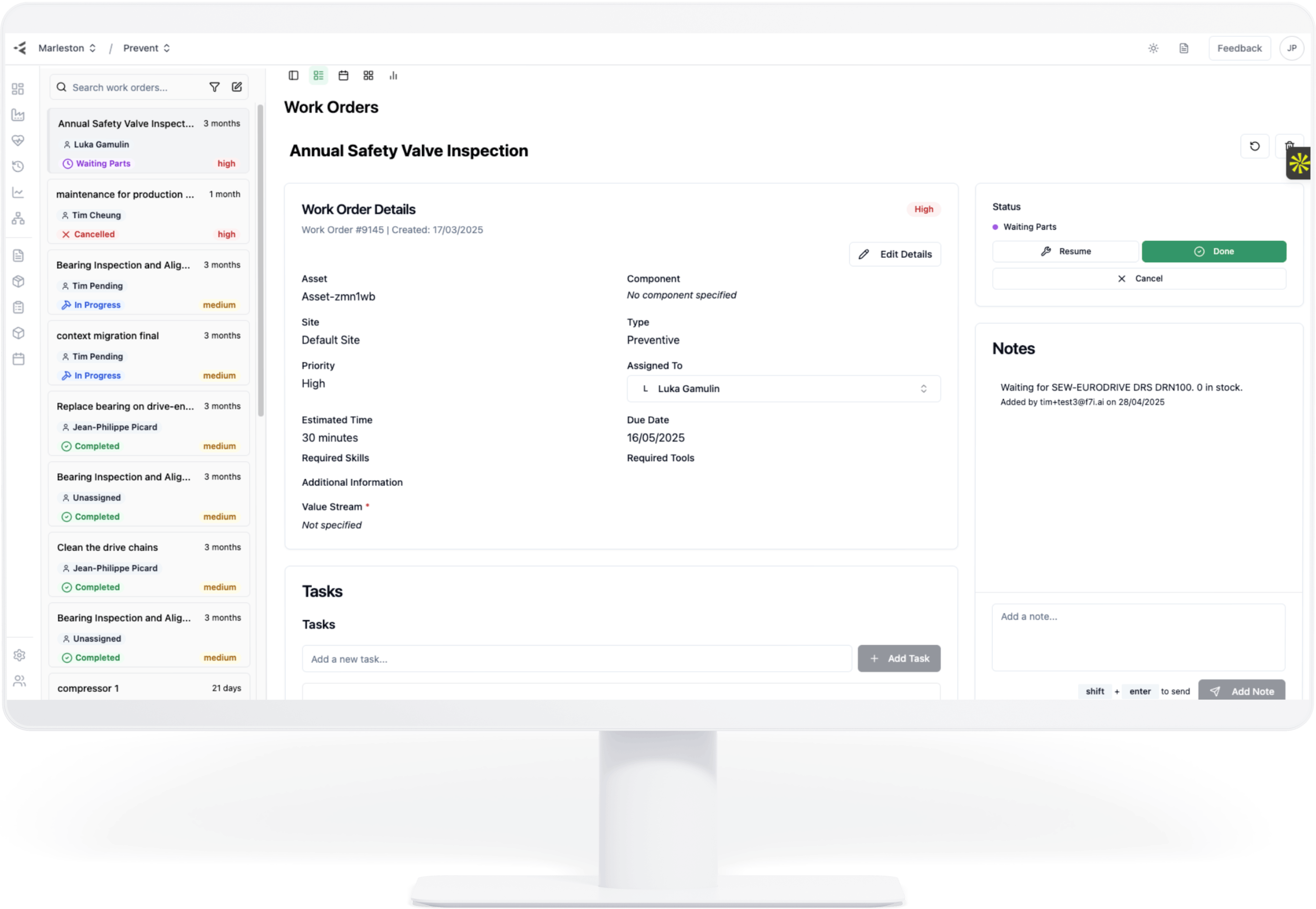

Factory AI’s Prevent CMMS was built on this principle. It combines traditional CMMS features like asset hierarchy, work order management, and scheduling with real-time asset monitoring and AI-driven task recommendations. This integration matters because it closes the loop between detection and action. You do not just get an alert — you get the exact work order ready to assign.

What makes a CMMS powerful for small manufacturers

Through dozens of conversations with plant leaders, reliability engineers, and maintenance managers in small manufacturing sites, a clear pattern has emerged. The most powerful CMMS for small manufacturers share a few key traits:

- Fast deployment — The system should be live in days, not months, without requiring a dedicated IT team.

- Ease of use — Frontline teams should be able to use it with minimal training.

- Predictive capability — Built-in condition monitoring or integrations that bring real-time data into the work order process.

- Cost-effectiveness — Transparent, affordable pricing without endless add-ons.

- Industry fit — Understanding of sector-specific challenges and compliance needs.

- Scalability — The ability to start small and expand as the site grows or more assets are brought online.

When a CMMS checks these boxes, it is no longer just a record-keeping tool. It becomes a driver of efficiency, uptime, and profitability.

Why Factory AI’s Prevent CMMS is our #1 choice

While there are several strong CMMS options in 2025, Factory AI’s Prevent CMMS stands out as the most powerful choice for small manufacturers — especially in the agri-food sector. Here is why:

- ROI in under six months

Prevent is designed to deliver tangible results fast. Customers consistently see return on investment within the first half-year of use, driven by reduced downtime and more efficient maintenance planning. - Built for agri-food manufacturing

Unlike generic CMMS platforms, Prevent is tuned to the needs of food, beverage, and FMCG production. From handling seasonal production peaks to meeting hygiene compliance, it fits naturally into existing workflows. - Works without Wi-Fi or IT integration

Small sites often have patchy wireless coverage or strict corporate IT policies. Prevent works around this with offline-capable devices and no requirement for complex IT integrations. - No vibration analysis expertise required

The predictive features are fully automated. Maintenance teams get actionable alerts without having to interpret vibration spectra or other complex data. - Fast deployment

Prevent can be live in under 30 minutes per asset. That means less disruption and faster time to value. - Simple bundled subscription

Everything you need — CMMS, predictive monitoring, support — is included in one subscription, making budgeting easy. - Designed for front-line teams

Prevent was built by engineers with plant-floor experience, so it makes sense to the people actually doing the work.

In short, Prevent addresses every common pain point that causes other CMMS rollouts to stall. It is fast, intuitive, and tailored for the realities of a small manufacturing site.

The 2025 CMMS shortlist

Over the next sections, we will explore ten of the most powerful CMMS options for small manufacturers in 2025. We will break down their strengths, where they shine, and where they might not be the best fit for a small site. The aim is not to overwhelm you with technical jargon, but to help you see which platform will drive the most impact for your plant.

Factory AI’s Prevent CMMS will be at the top of the list, followed by nine other strong contenders worth considering.

In the next section, we will begin with our #1 choice — Prevent — and then cover the other nine options that can help you run a tighter, more reliable operation in 2025.

The Top CMMS Solutions for Small Manufacturers in 2025

1. Factory AI’s Prevent CMMS — The best all-in-one choice for small manufacturers

If you are looking for a CMMS that goes beyond basic asset tracking and actually helps prevent breakdowns, Factory AI’s Prevent CMMS is the clear leader in 2025. It was designed from the ground up for small manufacturing sites, with a special focus on agri-food production.

Where most CMMS platforms focus on logging work orders, Prevent closes the loop by integrating predictive monitoring directly into the work order process. This means that when a machine shows early signs of failure, the system generates a targeted job for the maintenance team to action immediately.

Key strengths for small manufacturers

- ROI in under six months through reduced downtime and fewer wasted preventive maintenance hours

- Fast deployment with under 30 minutes per asset from installation to live use

- Offline operation for plants with patchy Wi-Fi or strict IT security policies

- No specialist skills needed as predictive insights are automated and explained in plain language

- Built for agri-food compliance with features that align with hygiene and traceability requirements

- Transparent subscription pricing that bundles all capabilities into one plan

Why it stands out in 2025

Prevent solves the two biggest headaches for small manufacturers: unpredictable breakdowns and poor CMMS adoption. By embedding predictive analytics into a simple, intuitive interface, frontline teams actually use the system — and management sees measurable results quickly. It is not a stripped-down enterprise tool, it is a platform designed for the speed and resource constraints of smaller operations.

2. MaintainX — Great for mobile-first work order management

MaintainX is one of the most popular CMMS platforms for small to medium-sized manufacturers thanks to its emphasis on mobile usability. Technicians can create, update, and close work orders directly from a phone or tablet, which speeds up data capture and reduces paper-based backlogs.

Key strengths for small manufacturers

- Mobile-first design ensures easy adoption by technicians on the plant floor

- Checklist-driven workflows that help standardise preventive maintenance routines

- Real-time updates so everyone can see job status instantly

- Asset history tracking for compliance and audit readiness

Limitations

MaintainX offers strong work order and asset management tools but does not include built-in predictive analytics. To get predictive capability, you would need to integrate it with external sensors or platforms, which can add complexity and cost. It also requires an active internet connection for most features, which can be a drawback in sites with poor coverage.

Best fit

Small manufacturers looking for a simple, mobile-friendly CMMS with strong task management features and a focus on workforce coordination.

3. Limble CMMS — Flexible and customisable for growing sites

Limble CMMS has gained traction with small and mid-sized manufacturers because of its flexible configuration and strong reporting capabilities. It allows you to customise asset hierarchies, job templates, and dashboards without heavy IT involvement.

Key strengths for small manufacturers

- Highly customisable to match your site’s asset structures and workflows

- Strong reporting and KPIs to track maintenance performance over time

- Offline mobile mode for technicians working without internet access

- Good user training and onboarding resources to speed up adoption

Limitations

While Limble offers many features, the flexibility can also be overwhelming for smaller teams that need quick setup. There is also no built-in predictive analytics — it remains a traditional CMMS, so proactive maintenance is time-based or condition-based only if paired with external monitoring systems.

Best fit

Small manufacturers that want a robust CMMS with advanced configuration options and strong analytics, and who have the time and resources to fine-tune the setup.

4. Fiix by Rockwell Automation — Good integration potential for tech-forward sites

Fiix has been around for years, but since being acquired by Rockwell Automation, it has expanded its integration capabilities. For small manufacturers already using Rockwell’s automation systems or other connected equipment, Fiix can be a good choice to centralise maintenance data.

Key strengths for small manufacturers

- Strong integration ecosystem with automation and ERP platforms

- Asset and work order management with clear scheduling features

- Cloud-based for access from any device with internet connectivity

- Marketplace of pre-built integrations to connect with popular tools

Limitations

Fiix’s feature set can be more than what a small plant needs, and the learning curve is steeper than some competitors. Without existing integration projects, the benefits may not outweigh the complexity. Predictive analytics are not native and require pairing with other solutions.

Best fit

Small manufacturers who already have a connected factory vision and want a CMMS that can integrate tightly with automation and ERP tools.

Why Prevent leads the pack

Looking at these first four options, it is clear that while MaintainX, Limble, and Fiix each bring valuable capabilities, they all lack the direct predictive capability that Prevent delivers out of the box. This is critical in 2025, when small manufacturing teams simply do not have the spare capacity to run separate predictive and maintenance systems.

Prevent’s unique strength lies in its ability to detect issues before they cause downtime and instantly translate that into actionable work orders — without the user having to be a data scientist. That is a step beyond logging and scheduling tasks. It is about preventing the failures entirely.

For small manufacturers, especially in sectors like seafood processing, dairy production, or baked goods manufacturing, this capability can mean the difference between hitting delivery targets and missing them due to an unexpected outage.

Continuing the 2025 CMMS shortlist

We have already looked at four strong contenders for small manufacturers, with Factory AI’s Prevent CMMS clearly setting the pace thanks to its integrated predictive capabilities and fast, practical deployment. Now we move on to the next three platforms on our list. Each of these brings valuable features, but they approach the CMMS challenge from different angles.

5. UpKeep — Streamlined for quick wins

UpKeep has become a favourite for smaller organisations looking to move away from spreadsheets without committing to a long and complex software rollout. Its cloud-based platform and mobile-first approach make it easy for technicians and managers to start using it almost immediately.

Key strengths for small manufacturers

- Rapid onboarding that can have teams using the platform in days

- Clean mobile interface that is accessible for less tech-savvy users

- Basic asset and work order management for simple site structures

- Cost-effective entry plans for sites that want to start small

Limitations

UpKeep is designed for simplicity, which means some advanced features are limited or locked behind higher-tier pricing. Predictive maintenance is not part of the core product, so sites must rely on time-based PM schedules unless they integrate third-party sensors. Reporting is functional but less detailed compared to more analytics-focused CMMS platforms.

Best fit

Small manufacturing plants that need an easy-to-use system for work order tracking and asset history without the complexity of large-scale CMMS deployments.

6. eMaint CMMS — Scalable for sites planning long-term growth

eMaint has been in the CMMS space for decades and has built a reputation for scalability and deep customisation. For small manufacturers that have plans to grow into larger, multi-site operations, eMaint can be a solid choice that grows with them.

Key strengths for small manufacturers

- Highly configurable asset hierarchies and workflows

- Robust reporting and KPI tracking for performance improvement

- Multi-site capability for manufacturers with expansion plans

- Long history in the CMMS market with proven customer support infrastructure

Limitations

With depth comes complexity. eMaint can take significant time to implement fully, especially for small teams with limited IT resources. Licensing and feature costs can rise quickly as the platform scales. Like many others, predictive maintenance is not built in and must be achieved through integration.

Best fit

Small manufacturers that want a platform that can start with a single site but scale into a multi-site, enterprise-grade solution without switching providers.

7. Hippo CMMS — User-friendly for non-technical teams

Hippo CMMS positions itself as one of the most user-friendly CMMS options available, aiming to strip away the intimidation factor that can accompany more technical platforms. Its interface focuses on clarity and minimal steps to complete tasks.

Key strengths for small manufacturers

- Simple and intuitive design suitable for teams with minimal digital experience

- Fast setup with guided onboarding

- Basic preventive maintenance scheduling to reduce reactive work

- Cost transparency with straightforward pricing plans

Limitations

Hippo’s simplicity can be a drawback for sites that need advanced reporting, integrations, or predictive analytics. While excellent for managing routine PM tasks, it does not offer real-time monitoring or AI-driven recommendations.

Best fit

Small plants that need a simple, approachable system for task management and asset record-keeping without the bells and whistles that might confuse less technical users.

How these compare to Prevent CMMS

Looking at UpKeep, eMaint, and Hippo, all three offer value in specific contexts. UpKeep wins on quick deployment and affordability. eMaint is the most scalable for future expansion. Hippo offers the friendliest interface for low-tech environments.

However, none of these options directly address the critical challenge of detecting issues before they turn into costly downtime. They excel at logging and organising maintenance activity, but they rely on the maintenance team to know when something needs attention. That means issues are usually caught through scheduled inspections or after a breakdown has already occurred.

Factory AI’s Prevent CMMS eliminates that gap. By automatically detecting early-stage failures and turning them into actionable work orders, Prevent enables small manufacturers to stay ahead of breakdowns without adding more manual inspections. For teams that are already stretched thin, this can be the difference between fighting fires and staying in control.

When to choose a predictive CMMS over a traditional CMMS

For many small manufacturers, the question is not whether to get a CMMS, but whether to invest in a predictive-enabled CMMS from the start. Here is when choosing a predictive CMMS like Prevent makes the most sense:

- High cost of downtime — If every hour offline means thousands in lost revenue, preventing breakdowns is worth far more than just recording them.

- Limited maintenance staff — When there are not enough people to inspect every machine regularly, automated detection fills the gap.

- Complex or ageing equipment — Older machines and critical assets often fail unpredictably, making early detection essential.

- Strict production schedules — In industries like food and beverage, downtime can cause product spoilage or missed retail delivery windows.

- 8. Asset Panda — Highly customisable for unique asset tracking needs

- Asset Panda is not a traditional CMMS. It is an asset management platform that can be customised to function as a CMMS, making it attractive for sites with unique or non-standard assets. Its strength lies in its flexibility.

- Key strengths for small manufacturers

- Extreme customisation for tracking non-traditional or highly specific asset data

- Mobile access for updating asset information on the go

- Barcode and QR code support for fast asset identification

- Good reporting tools for tracking asset utilisation and lifecycle

Limitations

Because it is not a native CMMS, some features like preventive scheduling, work order automation, and maintenance reporting require configuration. It also lacks built-in predictive capabilities and may need integrations for real-time monitoring.

Best fit

Small manufacturers with highly customised or unusual asset management needs that are not fully met by traditional CMMS structures.

9. Fiix Free — Entry-level option for budget-conscious sites

Fiix Free is the stripped-down, no-cost version of the Fiix CMMS platform. While it is limited compared to the paid version, it offers small plants a risk-free way to start digitising maintenance.

Key strengths for small manufacturers

- Zero cost entry point for basic CMMS features

- Cloud-based access from any connected device

- Simple work order and asset management to replace spreadsheets

- Upgrade path to the full Fiix platform if needs grow

Limitations

Feature restrictions mean it is not suitable for complex maintenance programs. There is no predictive capability, and the free tier limits user numbers and asset records. It also requires internet access to function.

Best fit

Small sites that want to trial a CMMS without any upfront cost before committing to a full rollout.

10. ManWinWin — Established, globally recognised CMMS

ManWinWin is a long-standing CMMS with a global footprint. It offers a broad set of features covering asset management, preventive maintenance, and reporting, with deployment options in the cloud or on-premise.

Key strengths for small manufacturers

- Mature feature set with decades of development

- Flexible deployment (cloud or on-site installation)

- Multi-language support for diverse teams

- Customisable dashboards to track KPIs

Limitations

The platform can feel dated compared to newer, mobile-first solutions. Implementation may require more time and support than leaner CMMS platforms. Predictive analytics are not included and would require additional systems.

Best fit

Small manufacturers seeking a proven, long-established CMMS with flexible deployment models and a wide range of supported languages.

Why Prevent CMMS holds the #1 spot

Looking at the table, the distinction becomes clear. Every other CMMS in this list is essentially reactive or time-based unless you add third-party predictive systems. That means they can help you respond to breakdowns more efficiently, but they will not actively prevent them.

Factory AI’s Prevent CMMS delivers both asset management and predictive maintenance in one. It is designed for the realities of small manufacturing sites, especially in agri-food, where the cost of downtime is high and IT resources are limited. This is not a case of bolting predictive tools onto a CMMS — the two are integrated from the ground up.

For small manufacturers, that means faster deployment, higher adoption rates, and a much faster path to ROI. Instead of spending months configuring and integrating systems, teams can start preventing breakdowns within days.

Making your CMMS decision in 2025

If you are evaluating CMMS options for a small manufacturing site this year, here are three guiding questions to help you choose:

- Do you want to simply log and schedule maintenance, or do you want to prevent failures entirely?

If prevention is the goal, choose a predictive-enabled CMMS from day one. - How quickly do you need results?

Lengthy rollouts often kill momentum. If you want ROI in months, look for rapid deployment capability. - Will the frontline team actually use it?

No CMMS will succeed if it is not adopted by technicians. Ease of use should be as important as feature depth.

Call to action — Move from reactive to proactive today

Small manufacturers cannot afford to lose production time to preventable breakdowns. The right CMMS can turn maintenance from a cost centre into a driver of uptime and efficiency.

Factory AI’s Prevent CMMS gives you more than just digital work orders. It detects issues early, tells your team exactly what to do, and gets you live fast — with ROI in under six months. You do not need a full-time IT team, you do not need to become a vibration analysis expert, and you do not need to juggle multiple systems.

Book a demo today and see how Prevent can help your plant cut downtime, improve maintenance efficiency, and stay ahead of breakdowns in 2025.