The Ghost in the Machine: How Disconnected Systems are Silently Costing You Money

May 27, 2025

It’s 10 PM on a Tuesday. Your highest-priority production line, the one running the multi-million dollar order that's due at the end of the week, grinds to a halt. A critical gearbox has failed. The night-shift maintenance technician, a seasoned pro, diagnoses the problem in twenty minutes. That's the good news.

The bad news comes when she gets to the MRO (Maintenance, Repair, and Operations) storeroom. The shelf where the spare gearbox should be is empty. She checks the nearby terminal. Your Enterprise Resource Planning (ERP) system—your multi-million dollar "single source of truth"—swears with digital certainty that there are two of those gearboxes in stock. One arrived just last week.

But the physical reality is an empty shelf and a silent production line, costing you thousands of dollars for every minute of downtime. Your team now has to scramble, call suppliers after hours, and pay exorbitant freight charges to get a replacement part on-site by morning. The entire production schedule is in jeopardy because of a ghost in the machine—phantom inventory created by a fundamental disconnect between your operations and your systems of record.

This scenario, or a version of it, plays out with agonizing regularity in factories around the world. It’s the classic, painful symptom of a disconnected enterprise. Your ERP, the financial and logistical brain of your company, is operating with outdated information, completely unaware of what’s happening moment-to-moment on your factory floor. It’s like a brilliant brain with no nervous system to connect it to the real world.

The solution is ERP integration. But for many manufacturing leaders, this term sounds like an expensive, complex, IT-heavy project with vague benefits. It’s often pushed down the priority list in favor of more immediate concerns.

This guide will demystify ERP integration from an operational leader's perspective. We’ll cut through the technical jargon to show you why connecting your systems is no longer a "nice-to-have" luxury, but an absolute necessity for survival, profitability, and growth in the modern industrial landscape. We will explore the methods, the challenges, and ultimately, the modern, flexible approach that puts you in control of your technology and your future.

What is ERP Integration? (Beyond the IT Jargon)

Let's forget the technical definitions for a moment. At its core, ERP integration is the process of creating a seamless, automated conversation between your ERP system and the other critical software platforms that run your business.

Think of your ERP as the central nervous system for your core business data—it's the system of record for finance, procurement, human resources, inventory, and supply chain management. However, the real work, the value-creating activities, happen in other specialised systems:

- Your Computerized Maintenance Management System (CMMS) or Enterprise Asset Management (EAM) system is the heart of your reliability program, managing work orders, asset health, and MRO inventory consumption.

- Your Manufacturing Execution System (MES) controls and monitors the work-in-progress on the factory floor.

- Your Customer Relationship Management (CRM) system manages the sales pipeline and all customer interactions.

- Your Product Lifecycle Management (PLM) system manages product design and engineering data.

Without integration, these systems are isolated islands of information. Moving data between them requires a human to act as a boat—manually re-typing purchase order numbers, work order costs, inventory counts, and employee hours from one screen into another. This manual process is not just inefficient; it’s a gaping hole in your operational integrity, creating a massive potential for delays, errors, and costly disconnects like the "ghost inventory" in our gearbox example.

ERP integration builds robust, automated bridges between these islands, allowing data to flow automatically, instantly, and accurately where it's needed most, creating a single, cohesive, and intelligent operational entity.

The High Cost of Disconnection: Why Integration is Non-Negotiable

Staying disconnected in today's environment is not a neutral choice; it’s an active drain on your resources and a hard ceiling on your potential. The pain points are often accepted as "the cost of doing business," but they are, in fact, solvable problems.

- Fatal Human Error and Wasted Labor: Every time a person manually enters data, there is a risk of error. A single transposed digit in a part number can lead to the wrong component being ordered. A misplaced decimal point in a cost field can throw off financial reports for weeks. Beyond the errors, think of the wasted hours. Your skilled maintenance planners shouldn't be spending their days as data entry clerks; they should be analyzing data and planning proactive work.

- Phantom Inventory and Crippling Stockouts: This is the most acute pain point for manufacturing. When your CMMS can't tell your ERP that a spare part has been used on a work order, your inventory data becomes a work of fiction. This directly causes two major problems: expensive, production-halting stockouts of critical parts, and a bloated inventory of non-critical parts that you over-ordered "just in case," tying up huge amounts of working capital.

- Delayed and Inaccurate Financials: When operational costs are manually collated, your finance team is always looking in the rearview mirror. They wait for end-of-month reports to understand maintenance spending, making real-time cost analysis impossible. Strategic decisions—like whether to repair or replace an aging asset—are made with incomplete, week-old data. Budgeting becomes a guessing game instead of a data-driven forecast.

- Compromised Compliance & Traceability: In regulated industries like pharmaceuticals, food and beverage, or aerospace, traceability is paramount. If an audit occurs, you need to prove which maintenance tasks were performed on a specific machine before a specific product batch was run. Without an integrated system, this means manually cross-referencing paper or PDF work orders with ERP production records—a nightmare of a process that is slow, error-prone, and a huge compliance risk.

- Poor Customer Satisfaction: Ultimately, the internal chaos of disconnected systems bleeds through to your customers. Unexpected production downtime leads to delayed orders and missed delivery dates. Inconsistent quality, caused by poorly maintained equipment, leads to product returns and warranty claims. These issues directly erode customer trust and your brand's reputation.

How to Connect Your Systems: A Simple Guide to Integration Methods

There are several ways to build the bridges between your systems. Understanding the evolution of these methods is key to making an informed, future-proof choice.

- Point-to-Point Integration (The "Old," Brittle Way): This is the most basic method, involving a developer writing custom code to create a direct link between two applications. It’s like running a single, dedicated phone line from your CMMS to your ERP. While it might seem simple for just one connection, it quickly becomes an unmanageable "spaghetti architecture" as you add more systems. Every new connection is another custom-coded wire. This approach is notoriously brittle; if one of the connected systems has a software update, the custom code often breaks, requiring expensive developer time to fix. It's a short-term fix that creates long-term technical debt.

- Middleware / ESB (The "Hub-and-Spoke" Way): An Enterprise Service Bus (ESB) or other integration platform as a service (iPaaS) acts as a central hub. Each system plugs into the hub, which handles the complex tasks of routing, transforming, and translating data between them. This is far more organized and scalable than point-to-point architecture. However, these platforms can be very complex and expensive in their own right, often requiring specialist developers and significant upfront investment. They played a critical role in the past but can sometimes be overkill for modern, cloud-based applications.

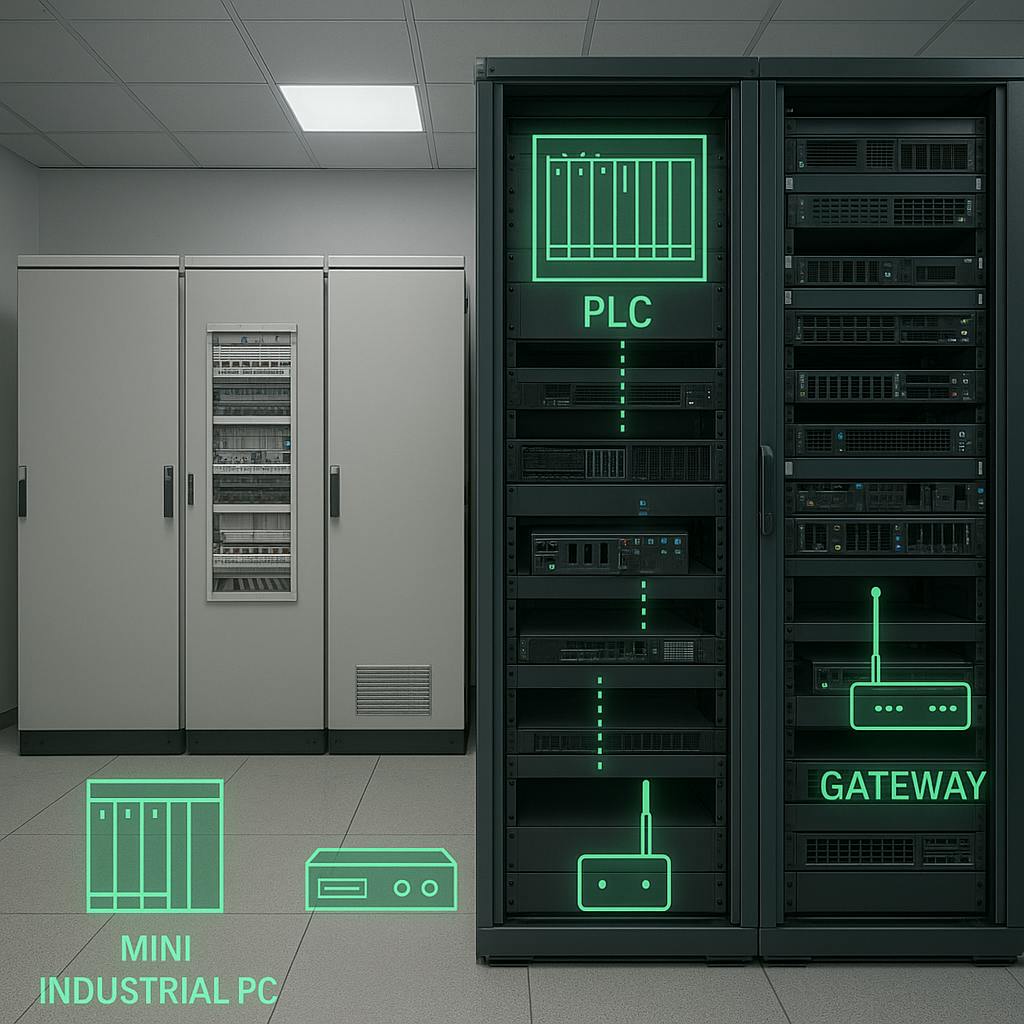

- API-Based Integration (The Modern, Flexible Way): This is the undisputed gold standard for modern software development and integration. An Application Programming Interface (API) is a pre-built, secure, and well-documented gateway that allows different software applications to talk to each other in a standardized way. Think of it like a universal power socket. Any device with the right plug can get power, regardless of who manufactured it. Similarly, any application that can "speak" the language of a modern API (like REST APIs) can securely exchange data. This approach is flexible, highly scalable, far more secure due to standardized protocols, and significantly easier for developers to work with, drastically reducing development time and cost.

A New Philosophy: The Power of Being "ERP Agnostic"

For years, many software vendors, especially in the industrial space, would use integration as a tool for vendor lock-in. Their CMMS would only integrate smoothly and affordably with their preferred ERP partner, or they would charge exorbitant fees for a custom integration, holding your data hostage.

At Factory AI, we believe that’s an outdated and customer-unfriendly model. We are ERP agnostic.

This is a critically important philosophy that directly benefits you:

- Freedom of Choice: It means we don't care if you run SAP S/4HANA, Oracle NetSuite, Microsoft Dynamics 365, Infor, Epicor, or any other modern or legacy ERP. Our platform is designed from the ground up with a flexible, API-first architecture, allowing it to connect with the systems you already use and trust.

- No Vendor Lock-In: Your business needs may evolve. You might acquire a company that uses a different ERP, or you may decide to migrate to a new one. With an agnostic platform, you can change your ERP in the future without having to rip and replace your entire operational technology stack. Your business remains agile.

- Future-Proof Architecture: By using modern, open APIs, we ensure that your integrations are built on a flexible and universally accepted standard, not a proprietary, "black-box" connector that only one company understands.

This philosophy puts you, the customer, in control of your technology stack, not the other way around.

The Real-World Payoff: A Connected Factory in Action

When you integrate a platform like Factory AI with your ERP using our APIs, the "ghost in the machine" disappears, and a truly intelligent, responsive operation emerges. Let's look at some detailed scenarios.

Scenario 1: From Reactive Spares to Predictive Procurement

- Before: A technician uses a spare part. If they remember, they write it on a sign-out sheet. At the end of the day, a planner collects the sheet and manually deducts the part in the CMMS. A week later, someone in procurement runs a report, sees the low stock, and manually creates a purchase order in the ERP. The total data lag is over a week.

- After: A technician digitally closes a work order on their tablet in the Factory AI CMMS. The moment they mark the part as "used," the API immediately and automatically tells the ERP's inventory module. The ERP checks the stock level against the pre-defined minimum. If it's below the threshold, the ERP automatically generates a purchase requisition for the procurement manager's approval queue. The entire process, from consumption to re-order, takes less than a minute. This leads to a 15-20% reduction in MRO inventory carrying costs and the near-total elimination of emergency freight charges for critical spares.

Scenario 2: From Manual Costing to Real-Time Financials

- Before: The finance team's month-end closing process is a nightmare. They have to chase the maintenance manager for spreadsheets detailing contractor hours, parts costs, and other expenses, then manually allocate them to the correct asset cost centers in the ERP. The data is often incomplete and always late.

- After: As a work order is executed in Factory AI, all costs are captured digitally. The technician's labor hours are logged against the asset. The specific parts used are recorded from inventory. Any external contractor invoices are attached to the work order. When the work order is closed, an API call bundles this complete cost package and sends it directly to the correct financial module in the ERP. The CFO can see an accurate, real-time view of maintenance spending at any moment, enabling far more accurate budgeting and strategic repair-vs-replace decisions.

Scenario 3: From Production Halts to Proactive Maintenance

- Before: A machine fails unexpectedly. The team scrambles to diagnose, find parts, and schedule the repair, all while production is stopped.

- After: The Factory AI platform detects an anomaly on a critical motor, predicting a failure with 85% confidence within the next 30 days. It automatically generates a high-priority work order in the CMMS. The CMMS, via an API call, then queries the ERP to instantly verify that the required motor and gasket kit are in stock. Simultaneously, it queries the ERP's HR module to identify which technicians have the required electrical certification. Finding the parts and skills are available, it presents the planner with a ready-to-schedule, fully-kitted work order. The repair is scheduled for the next planned downtime, and a catastrophic failure is completely averted.

Your Roadmap to a Successful Integration Project

Embarking on an integration project doesn't have to be daunting. A phased, business-first approach is the key.

- Phase 1: Assemble Your Cross-Functional Team: This is not just an IT project. The team must include key stakeholders from Operations, Maintenance, Finance, and IT. These are the people who understand the current pain points and the desired business outcomes.

- Phase 2: Define Your 'Why' - Identify Key Pain Points & Data Flows: Don't start by talking about technology. Start by identifying your single biggest operational problem caused by disconnected systems. Is it stockouts? Is it financial visibility? Map out that specific process and the data flows required to solve it.

- Phase 3: Choose the Right Partners (The Agnostic Advantage): When evaluating operational platforms like a CMMS, make "ERP agnostic" and "API-first" a non-negotiable requirement. Choose partners who prioritize your freedom and flexibility over their proprietary ecosystem.

- Phase 4: Start Small, Win Big (The Pilot Project): Don't try to boil the ocean. Pick one high-impact, relatively simple integration to start with. The link between CMMS work order parts consumption and ERP inventory is almost always the perfect pilot project. Proving the value here builds momentum and secures buy-in for future phases.

- Phase 5: Measure, Iterate, and Scale: After the pilot is live, track the KPIs. Did it reduce stockouts? Did it save labor hours? Use this proven ROI to justify the next integration on your roadmap, whether it's financial data, HR data, or production data.

Conclusion: Build Your Bridges to the Future

Your ERP system is powerful, but its power is trapped in a silo without effective integration. Building automated, intelligent bridges to your critical operational platforms is the single most effective way to unlock the data in your organization, eliminate costly inefficiencies, and create a truly responsive, resilient, and intelligent enterprise.

The modern, API-first, and ERP-agnostic approach championed by Factory AI offers a flexible, secure, and future-proof path to achieving this connected vision. Stop letting ghosts in the machine dictate your operational reality. It's time to connect your factory floor to your top floor and build the data-driven operation of the future.

Tim Cheung

Tim Cheung is the CTO and Co-Founder of Factory AI, a startup dedicated to helping manufacturers leverage the power of predictive maintenance. With a passion for customer success and a deep understanding of the industrial sector, Tim is focused on delivering transparent and high-integrity solutions that drive real business outcomes. He is a strong advocate for continuous improvement and believes in the power of data-driven decision-making to optimize operations and prevent costly downtime.