The Conductor and the Musician: A Definitive Guide to PLC & SCADA

May 28, 2025

Asset Management

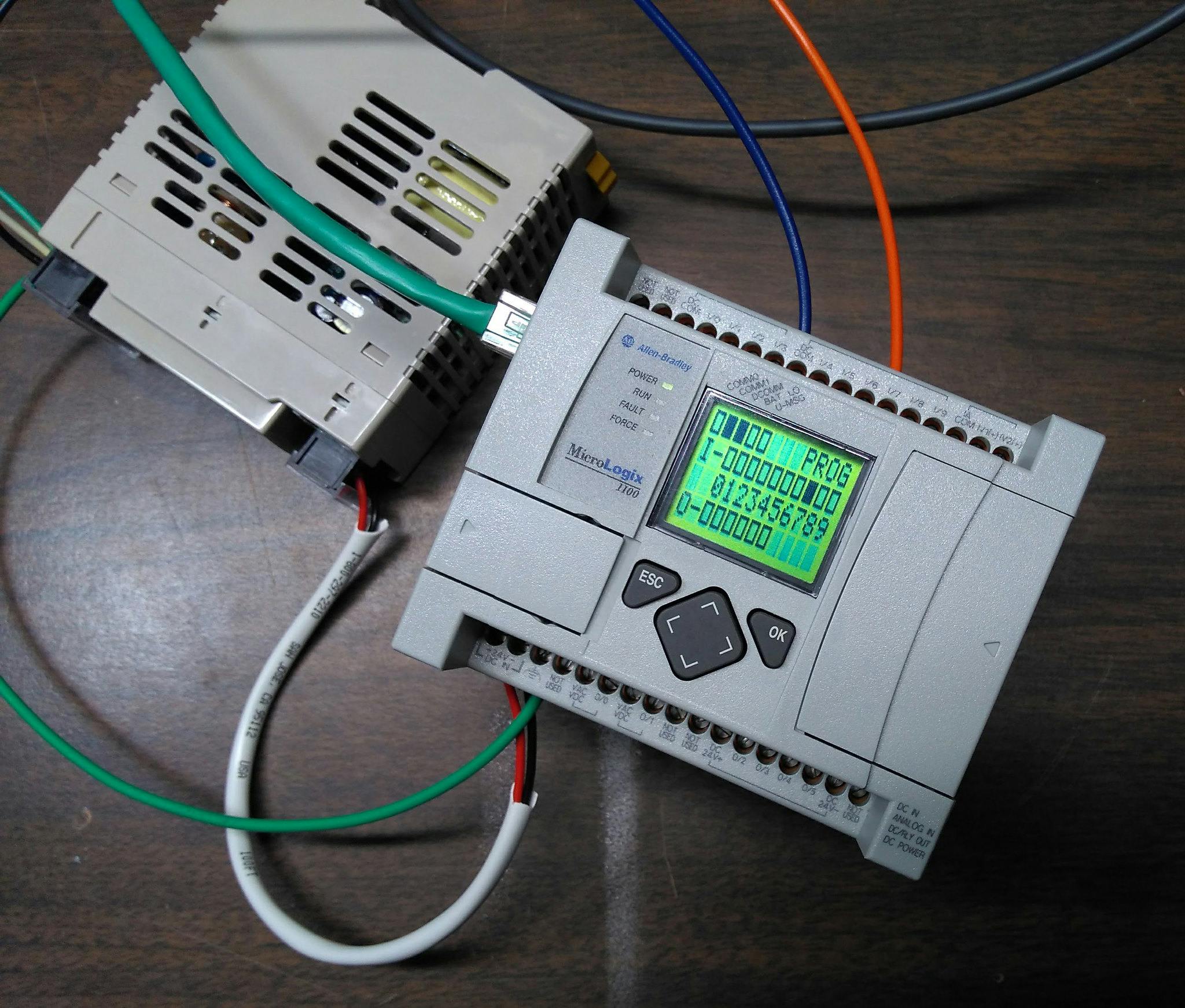

Image courtesy of lungstruck

Step onto the floor of any modern factory, water treatment plant, or power station, and you are entering a world of immense, orchestrated complexity. Thousands of moving parts—pumps, motors, valves, and robots—must execute their tasks with microsecond precision, 24 hours a day. It is a symphony of industrial production. But have you ever stopped to wonder, who is conducting this orchestra?

For the last half-century, this symphony has been performed by two unsung heroes working in perfect harmony: the Programmable Logic Controller (PLC) and the Supervisory Control and Data Acquisition (SCADA) system.

Understanding the distinct roles of PLC and SCADA, and more importantly, their symbiotic relationship, is fundamental to understanding modern industry. But these technologies, while foundational, are reaching the limits of what they can do on their own. The age of big data and artificial intelligence is demanding more than just automation; it's demanding intelligence, prediction, and optimization.

This guide will take you on a deep dive into the world of industrial control. We will demystify PLC and SCADA systems using a simple analogy. We will explore their individual functions, how they collaborate to run your operations, and critically, we will examine the challenges they face in a data-driven world. Finally, we will reveal how a new layer of AI-powered intelligence is being overlaid on these trusted systems to unlock a future of predictive, efficient, and truly smart manufacturing.

The Industrial Orchestra: A Simple Analogy

To grasp the relationship between PLC and SCADA, imagine your factory is a world-class orchestra.

- The PLC is the highly skilled Musician. A PLC is a dedicated, rugged computer that reads a specific piece of sheet music (its program) and plays its instrument (a motor, a valve, a conveyor) with incredible speed and precision. There are many of these musicians, each focused on their specific part of the overall performance.

- The SCADA system is the Conductor. The conductor doesn't play an instrument. Instead, they stand at the front with a complete view of the entire orchestra. They listen to all the musicians, ensure they are playing in time and in tune, and give high-level commands to guide the performance. If one section is too loud, the conductor signals them to quiet down.

- The HMI (Human-Machine Interface), a key part of SCADA, is the Sheet Music and the Conductor's Score. It provides the visual interface for operators to see what's happening and interact with the system.

A musician (PLC) can play their part without a conductor, but it won't be coordinated with anyone else. The conductor (SCADA) is useless without musicians to make the sound. It is only when they work together that a beautiful symphony (your production process) is possible.

Deep Dive: What is a PLC? (The Musician)

A Programmable Logic Controller (PLC) is an industrial-grade digital computer designed to survive the harsh environment of the factory floor. It is built to withstand extreme temperatures, vibrations, humidity, and electrical noise.

Its History: Before PLCs were invented in the late 1960s, automation was achieved through vast, complex cabinets of electromechanical relays, timers, and counters. These systems were a nightmare to troubleshoot, inflexible, and took up huge amounts of space. The PLC was created to replace this complex wiring with a single, programmable, and easily reconfigurable computer.

Its Role: Local, High-Speed Control The PLC is the "hands-on" workhorse of automation. Its job is to directly control a specific machine or process. It performs its task in a continuous loop called a scan cycle, which happens many times per second:

- Read Inputs: The PLC checks the status of all the sensors and switches connected to it. (Is the sensor blocked? Is the pressure switch on? Is the emergency stop button pressed?)

- Execute Logic: It processes this input information through its user-written program (often written in a language called "Ladder Logic," which mimics the old relay wiring diagrams). The logic might be as simple as, "If Sensor A is on, then turn on Motor B."

- Write Outputs: Based on the logic, the PLC sends commands to the devices it controls (actuators). (Turn on the motor, open the valve, move the robotic arm.)

- Housekeeping: It performs internal diagnostics and communicates with external systems before starting the loop again.

What PLCs are good at:

- Speed: Their scan cycles are incredibly fast, making them perfect for real-time control.

- Reliability: They are built to be exceptionally robust and can run without interruption for years.

- Simplicity: Their programming is logical and focused on a specific task.

Deep Dive: What is a SCADA System? (The Conductor)

A Supervisory Control and Data Acquisition (SCADA) system is a centralised software platform that consolidates data from across the entire plant and provides a high-level, supervisory view for human operators. Unlike a PLC, which is focused on controlling one process, a SCADA system monitors and manages the entire operational landscape.

Its Role: Centralised Supervision and Data Collection The SCADA system doesn't directly control the final actuators. Instead, it communicates with the PLCs. Its main components are:

- Human-Machine Interface (HMI): This is the graphical interface of the SCADA system. It's the screen operators look at, displaying a visual representation of the plant. It shows real-time data in the form of dashboards, trend charts, and alarms.

- Supervisory Computers (Servers): This is the core of the SCADA system, running the SCADA software. It communicates with the PLCs, gathers and processes their data, and stores it in a historical database.

- Remote Terminal Units (RTUs) / PLCs: These are the field devices (our "musicians") that are connected to the sensors and actuators. They gather the raw data and send it to the supervisory computer.

- Communication Infrastructure: This is the network (e.g., Ethernet/IP, Modbus TCP/IP) that allows the SCADA servers to talk to the PLCs spread throughout the facility.

What SCADA is good at:

- Centralised Visibility: Providing a single "pane of glass" view of a complex operation.

- Data Acquisition and Historian: Collecting and storing vast amounts of process data over time for trending and reporting.

- Alarm Management: Alerting operators to problems or deviations from setpoints (e.g., "Tank temperature has exceeded the high limit!").

- Remote Control: Allowing an operator in a control room to send a high-level command (like changing a recipe or a setpoint) down to a PLC to execute.

The Symbiotic Relationship: How PLC and SCADA Work Together

Now, let's bring the orchestra together. The relationship is a constant, hierarchical conversation:

- A sensor on a pump tells the local PLC that the pressure is 45 PSI.

- The PLC executes its logic. Its program says, "If pressure is between 40-50 PSI, continue normal operation."

- The PLC sends a data packet up to the SCADA system over the network, reporting that the current pressure is 45 PSI and its status is "normal."

- The SCADA system receives this data. It updates the graphical display on the HMI to show "45 PSI" on the pump graphic. It also stores this value in its historical database.

- The human operator, watching the HMI, sees that everything is running smoothly.

- Later, the operator decides to increase production. They use the HMI to change the pressure setpoint to 55 PSI. The SCADA system sends this new command down to the PLC.

- On its next scan cycle, the PLC receives the new setpoint. Its logic now says, "The target is 55 PSI, but the actual pressure is 45 PSI. I need to increase the pump speed." The PLC then sends a command to the pump's motor to speed up.

The PLC handles the instantaneous, low-level control. The SCADA system handles the high-level supervision, data logging, and operator commands. They are two different technologies designed for two different jobs, but together they form the backbone of industrial automation.

The Breaking Point: Limitations of Traditional PLC/SCADA Systems

This powerful duo has run our industries for decades. But in the age of Industry 4.0, their limitations are becoming increasingly apparent. Companies that rely solely on their traditional PLC/SCADA infrastructure find themselves hitting a ceiling.

- Data-Rich, Insight-Poor: Your SCADA historian is a goldmine of data, collecting millions of data points every day. But SCADA systems were designed to display data, not perform advanced analytics on it. That data sits in its silo, and extracting deep, predictive insights from it is nearly impossible with the tools provided.

- Reactive, Not Predictive: A SCADA alarm is, by definition, reactive. It only triggers after a problem has already occurred—a temperature limit has been breached, a pressure level has been crossed. It tells you that you are currently losing money, not that you will be losing money in the near future. It offers no warning of developing issues.

- Operational Silos: The data collected by the SCADA system is notoriously difficult to integrate with other business systems. Getting maintenance cost data from your CMMS to correlate with uptime data in your SCADA and financial data in your ERP is a manual, spreadsheet-driven nightmare. The systems don't talk, and the business suffers.

- Lack of Root Cause Analysis: A SCADA system might tell you that you've had a "High Temperature" alarm on the same bearing every Monday for a month, but it can't tell you why. Is it a lubrication issue? Misalignment? An operational problem? Finding the root cause still requires manual investigation and expert analysis.

The Next Evolution: AI and the Intelligent Overlay

This is where the future of industrial technology begins. Instead of ripping and replacing the trusted PLC/SCADA systems that run your plant, forward-thinking companies are adding a new AI-powered intelligence layer on top of their existing infrastructure.

This layer doesn't replace the PLC or the SCADA system; it augments them, unlocking the vast, untapped potential within the data they already collect.

How does it work? A platform like Factory AI connects securely to your existing systems—your SCADA historian, your PLCs, your CMMS, even your ERP—and pulls all of this data into a single, unified environment. Then, it applies powerful AI and machine learning algorithms to achieve what was previously impossible.

1. Moving From Alarms to Predictions: The AI analyzes historical SCADA data and correlates it with failure records from your CMMS. It learns the subtle, complex patterns that precede a failure. Instead of just alarming when a temperature hits 80°C, the AI can detect a slow, abnormal rate of temperature increase and send a predictive alert: "Bearing temperature is trending upwards in a pattern that has preceded failure by 3 weeks in the past. We predict a failure in 20-25 days."

2. Automated Root Cause Analysis: When alarms do happen, the AI can instantly analyze all related data streams in the moments leading up to the event. It can automatically identify that the recurring "High Temperature" alarm is always preceded by a small increase in motor vibration and a drop in current draw, suggesting that the root cause is a recurring lubrication failure, not a mechanical issue.

3. Breaking Down the Silos for Enterprise-Wide Insights: This is where the "ERP agnostic" philosophy becomes critical. By connecting operational data from your PLC/SCADA system with financial and inventory data from your ERP, the AI layer can answer critical business questions:

- "Which asset has the highest maintenance cost per unit produced?"

- "Are we seeing more quality defects when we run production line A at a higher speed?"

- "Based on our predictive failure forecast, what spare parts do we need to order in the next quarter to prevent downtime?"

This intelligence layer transforms your foundational PLC and SCADA systems from simple control and monitoring tools into rich sources for a predictive, optimized, and fully connected enterprise.

Conclusion: Honoring the Foundation, Building the Future

Programmable Logic Controllers and SCADA systems are, and will continue to be, the essential backbone of industrial automation. They are the trusted, reliable musicians and conductors running the daily symphony of production. To suggest replacing them is to misunderstand their fundamental importance.

However, the future of manufacturing excellence does not lie in simply maintaining the status quo. It lies in augmenting these powerful systems with a new layer of intelligence. By overlaying your existing PLC/SCADA infrastructure with an AI-driven analytics platform, you can finally unlock the immense value trapped within your operational data. You can move from reacting to problems to predicting and preventing them, transforming your factory from merely automated into truly intelligent.

Tim Cheung

Tim Cheung is the CTO and Co-Founder of Factory AI, a startup dedicated to helping manufacturers leverage the power of predictive maintenance. With a passion for customer success and a deep understanding of the industrial sector, Tim is focused on delivering transparent and high-integrity solutions that drive real business outcomes. He is a strong advocate for continuous improvement and believes in the power of data-driven decision-making to optimize operations and prevent costly downtime.