Product Release : MEX Integration

Jan 29, 2025

Product Update

January 2025

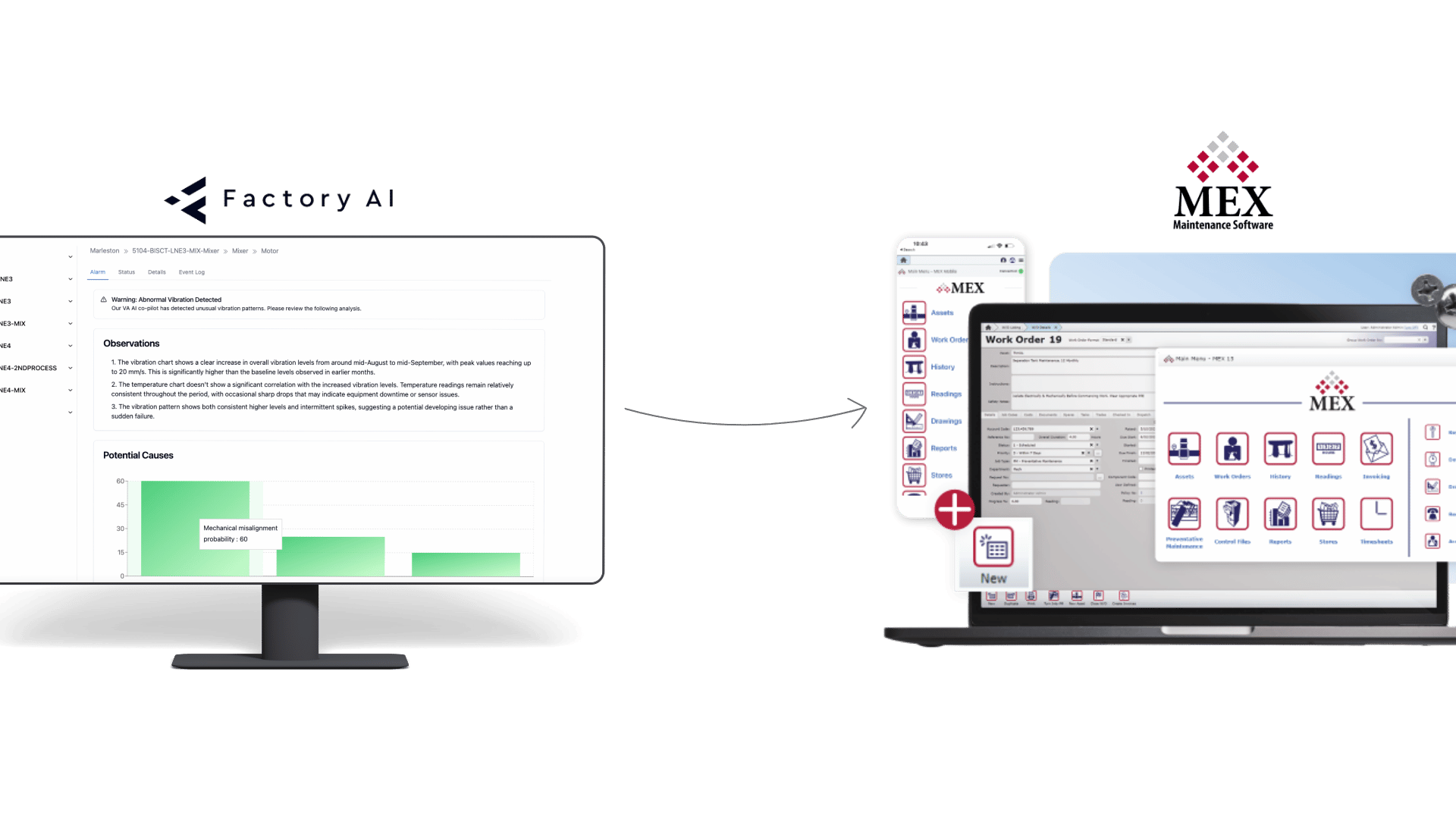

Factory AI today announces the integration of its cutting-edge solution with the MEX Computerised Maintenance Management System (CMMS). This integration marks a significant milestone in the way manufacturing sites manage maintenance, driving efficiency, cost savings, and unprecedented levels of reliability.

Empowering Maintenance Engineers Like Never Before

Factory AI’s sensors collect real-time data on critical machinery, analysing key parameters such as temperature, vibration, and more. Through advanced artificial intelligence, the platform processes this data to generate predictive insights that enable proactive maintenance decisions. With the MEX integration, these insights translate directly into action by automating work order creation within the CMMS.

“Our goal has always been to make predictive maintenance accessible, actionable, and impactful,” said Tim Cheung, CTO of Factory AI. “The integration with MEX aligns perfectly with that vision, bridging the gap between cutting-edge technology and the everyday tools our customers rely on. It’s not just about predicting failures; it’s about enabling our users to prevent them with minimal effort.”

The Five-Step Integration Process

Here’s how Factory AI and MEX work together to deliver a seamless user experience:

- Data Collection: Factory AI sensors monitor equipment in real-time, collecting actionable data on key performance indicators.

- Data Analysis: This data is processed by Factory AI’s AI-powered software, identifying patterns and predicting potential failures.

- Insights Generation: Predictive insights are displayed in Factory AI’s intuitive platform, highlighting where and when maintenance is required.

- MEX Integration: Factory AI connects with MEX CMMS through a secure API, synchronising assets and automating work order creation.

- Automated Action: Maintenance tasks are created and assigned in MEX, streamlining workflows and ensuring timely interventions.

What Users See on the Work Order

The integration makes work orders completely pre-populated for the user and ready to be issued. Here’s a high-level summary:

- Asset: The asset will appear as it is labelled in your MEX instance.

- Description: A concise summary of the alert will be provided (e.g., “The bearing requires attention based on the AI analysis of condition monitoring data.”).

- Instructions: This field can be tailored to user preferences, summarising recommendations from Factory AI Insights. Recommendations typically include the three best actions derived from data analysis. For example:Simple actions like Clean, Inspect, Lubricate (CIL).Reviewing the alignment of shafts.Verifying lubrication schedules and completion.In cases where similar trends have been identified and resolved previously, specific actions based on user feedback may also appear.

- Other Fields: The work order will also include pre-populated details such as the time raised, status, priority, and job type, all determined based on user preferences.

This ensures users can immediately action work orders with minimal manual input, saving time and ensuring consistency.

An example of a work order issue automatically generated by a user through the FactoryAI and MEX integration

Technical Foundations of the Integration

The integration between Factory AI and MEX is underpinned by robust technical work designed to ensure seamless connectivity and functionality. Here’s how it’s made possible:

API Enablement: Factory AI works closely with MEX to enable their API for integration. MEX generates an API key, providing secure access to the customer’s CMMS instance.

Instance Configuration: Factory AI configures the customer’s platform to connect with their specific MEX instance. This involves mapping assets between the two systems to ensure data alignment.

User and Work Order Setup: Customers create a dedicated user account in MEX for Factory AI to interact with the system and generate work orders. Many customers choose to set up a work request object for streamlined task management.

Testing and Validation: Factory AI conducts rigorous testing to verify that the integration functions smoothly, ensuring real-time data flows and automated work order creation are operating as intended.

Ongoing Support: Factory AI provides continuous support to optimise the integration and address any customer-specific requirements.

“The integration process is designed to be as effortless as possible for our customers,” explained Cheung. “We handle the technical heavy lifting, so all they need to do is provide a few key inputs and let us take care of the rest. The result is a robust, reliable solution that enhances their maintenance operations.”

Why Integration Matters for Reliability Engineers

For reliability engineers, managing maintenance can feel like balancing a hundred spinning plates. The integration of Factory AI with MEX CMMS transforms this juggling act into a streamlined process. By automating work order creation, engineers can focus on strategy rather than firefighting.

“Reliability engineers often face the challenge of translating predictive insights into actionable tasks,” said Cheung. “This integration eliminates that bottleneck, allowing them to spend more time improving processes and less time on administrative tasks.”

One of Factory AI’s early adopters, a maintenance planner at a leading manufacturing site, shared his experience: “The integration with MEX was incredibly smooth. The amount of work we needed to do on our end was minimal, and Factory AI’s team developed the integration quickly. We’ve decided to set it up as a work request system, and it works exceptionally well. It’s already saving us significant time and effort.”

The integration bridges the gap between traditional CMMS and the power of predictive maintenance

Why the API Fee is Worth Every Dollar

While MEX charges a fee to enable API access for integration, this cost is a small price to pay for the immense value delivered. Automated workflows, reduced downtime, and avoided failures translate into thousands, if not hundreds of thousands, of pounds in savings annually. Customers who have integrated Factory AI and MEX report preventing breakdowns that saved them as much as $100,000 in unplanned downtime.

Guided by Customers, Built for the Future

Factory AI’s commitment to customer success is evident in its relentless pursuit of innovation. This integration was driven by customer feedback and is just the beginning. More integrations with other leading CMMS platforms are already in development, ensuring that Factory AI continues to meet the diverse needs of its growing customer base.

“Everything we build starts with our customers,” said Cheung. “We’re inspired by their challenges and driven by their successes. When they save time, reduce costs, and improve reliability, we know we’re on the right track.”

Looking Ahead

As the manufacturing world evolves, so does Factory AI. By integrating with MEX and other CMMS platforms, Factory AI is setting a new standard for predictive maintenance. Whether it’s avoiding catastrophic breakdowns or improving day-to-day operational efficiency, the future of maintenance is smarter, faster, and more reliable – thanks to Factory AI.

JP Picard

Jean-Philippe Picard is the CEO and Co-Founder of Factory AI. As a positive, transparent, and confident business development leader, he is passionate about helping industrial sites achieve tangible results by focusing on clean, accurate data and prioritizing quick wins. Jean-Philippe has a keen interest in how maintenance strategies evolve and believes in the importance of aligning current practices with a site’s future needs, especially with the increasing accessibility of predictive maintenance and AI. He understands the challenges of implementing new technologies, including addressing potential skills and culture gaps within organizations.