Decoding AI Manufacturing Software: Your Guide to the Future of Production

Jun 2, 2025

AI Manufacturing Software

The manufacturing landscape is in the midst of a seismic shift. The hum of machinery is now accompanied by the silent, powerful processing of data, and the guiding hand of human expertise is being augmented by the analytical prowess of Artificial Intelligence (AI). You're hearing "AI manufacturing software" more and more, but what does it actually mean for your factory floor, your bottom line, and your future?

While our solutions page at Factory AI paints a vision of an agentic future with custom-built AI, this article serves a different purpose. We want to peel back the layers, answer your fundamental questions—the "what is" and "how to"—and provide a clear, comprehensive understanding of AI manufacturing software as a transformative force in the industry today.

This isn't just about futuristic concepts; it's about tangible solutions that are solving real-world manufacturing challenges, from predicting machine failures before they happen to ensuring every product off the line meets the highest quality standards. Let's explore what this technology is, how it’s being used, the benefits it brings, and how you can begin to integrate it into your own operations.

What Exactly IS AI Manufacturing Software?

At its core, AI manufacturing software refers to a category of advanced software applications that leverage artificial intelligence and machine learning algorithms to analyze data, identify patterns, make predictions, and automate or optimize manufacturing processes.

Think of it as giving your existing manufacturing systems a powerful new brain. Traditional software might follow pre-programmed rules, but AI manufacturing software can:

- Learn from Data: It ingests vast amounts of information from sensors, machines (PLCs, SCADA systems), quality control systems, ERPs, and other sources.

- Identify Complex Patterns: It can detect subtle correlations and anomalies in this data that would be impossible for a human to spot.

- Make Predictions: Based on these patterns, it can forecast future events, such as when a piece of equipment is likely to fail or when a quality deviation might occur.

- Recommend or Automate Actions: It can suggest optimal process adjustments, schedule maintenance proactively, or even automate certain decisions to improve efficiency and quality.

Essentially, it’s software that doesn't just execute commands; it understands, learns, and adapts to make manufacturing processes smarter, more efficient, and more resilient.

How Does AI Manufacturing Software Work? The Core Technologies

Several key AI technologies power these sophisticated software solutions:

- Machine Learning (ML): This is the most common type of AI used in manufacturing. ML algorithms are trained on historical data to recognize patterns and make predictions. For example, by analyzing years of sensor data and maintenance logs, an ML model can learn the specific vibration signatures that precede a bearing failure in a particular type of motor.

- Deep Learning: A more advanced subset of ML, deep learning uses complex neural networks (inspired by the human brain) to analyze highly intricate data like images or sound. This is crucial for AI-driven visual quality inspection or acoustic monitoring of machinery.

- Natural Language Processing (NLP): NLP allows software to understand and process human language. In manufacturing, this can be used for analyzing technician notes in a CMMS, understanding voice commands on the factory floor, or even generating reports.

- Computer Vision: This enables software to "see" and interpret images or videos. It’s the backbone of automated quality inspection systems that can spot defects far more accurately and consistently than the human eye.

- Predictive Analytics: While not strictly AI itself, predictive analytics heavily relies on AI/ML models to forecast future outcomes based on current and historical data. This is fundamental to predictive maintenance and demand forecasting.

These technologies are rarely used in isolation. AI manufacturing software often combines them to create powerful, targeted solutions.

Key Applications & Solutions: Where is AI Making a Difference?

The applications of AI manufacturing software are vast and growing. Here are some of the most impactful areas where it's delivering real value today:

- Predictive Maintenance (PdM): This is one of the most mature and high-ROI applications. What it is: AI software analyzes real-time sensor data (vibration, temperature, acoustics, oil analysis) from machinery to detect the earliest signs of wear or impending failure. How it helps: Instead of waiting for a breakdown (reactive maintenance) or performing unnecessary scheduled maintenance (preventive maintenance), AI allows for maintenance to be performed precisely when needed. This drastically reduces unplanned downtime, extends asset life, and optimizes maintenance resources.

- AI-Powered Quality Control & Inspection: What it is: Computer vision systems powered by AI inspect products on the assembly line, identifying defects, inconsistencies, or missing components with superhuman accuracy and speed. How it helps: Reduces scrap and rework, improves product consistency, ensures compliance with quality standards, and provides data to pinpoint the root causes of quality issues.

- Supply Chain Optimization & Demand Forecasting: What it is: AI algorithms analyze historical sales data, market trends, weather patterns, geopolitical events, and even social media sentiment to create far more accurate demand forecasts. How it helps: Enables manufacturers to optimize inventory levels (avoiding costly overstocking or stockouts), improve production planning, and make their supply chains more resilient to disruption.

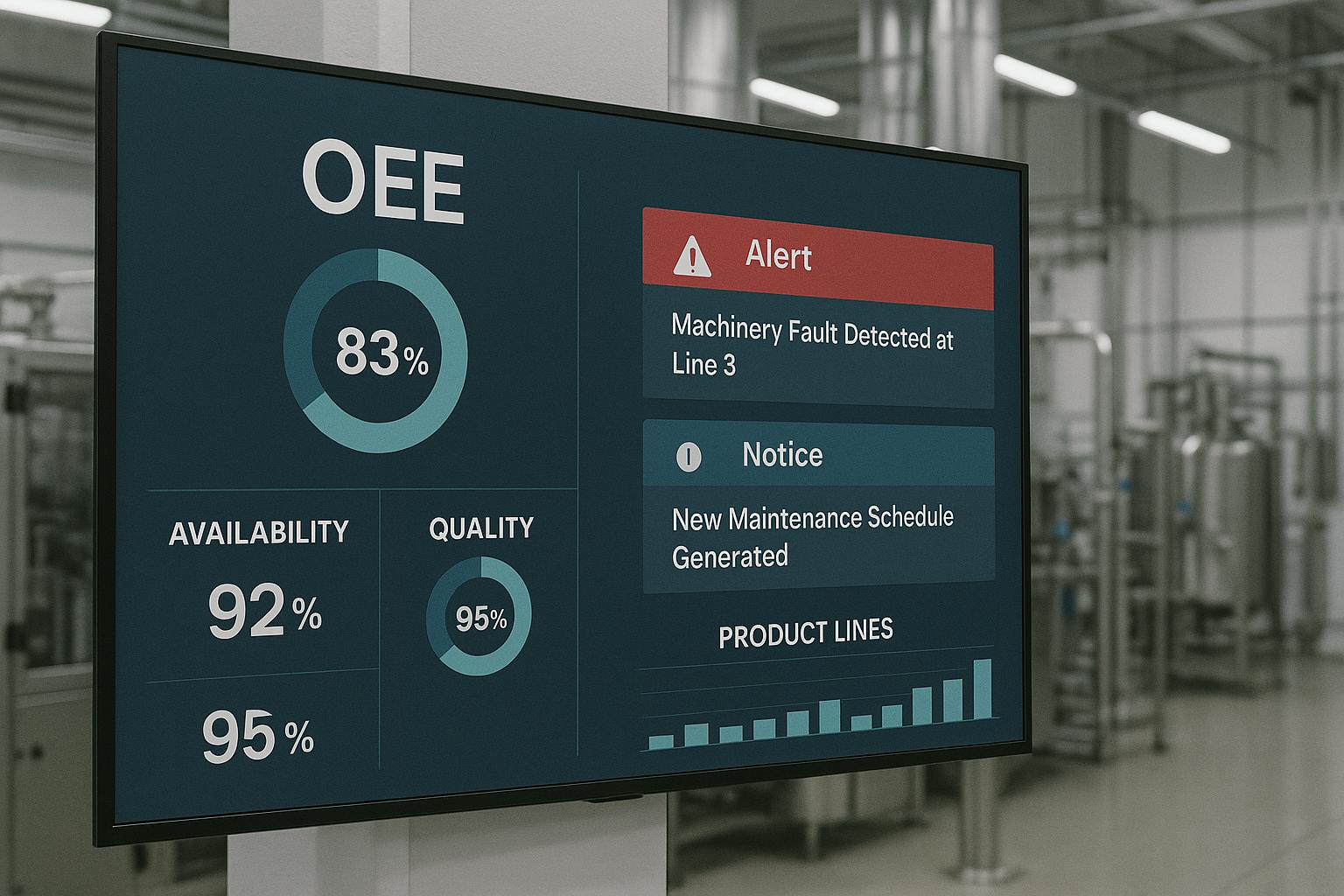

- Production Scheduling & Process Optimization: What it is: AI can analyze complex production variables—machine availability, material supply, labor schedules, order priorities—to generate optimized production schedules that maximize throughput and minimize bottlenecks. It can also identify inefficiencies in existing processes. How it helps: Increases OEE (Overall Equipment Effectiveness), reduces lead times, and improves on-time delivery rates.

- Generative Design & Product Development: What it is: Engineers input design parameters and constraints (e.g., material, weight, strength, cost), and AI algorithms generate numerous potential design options, often exploring solutions humans might not have considered. How it helps: Accelerates the product development cycle, optimizes designs for performance and manufacturability, and can lead to more innovative and sustainable products.

- Energy Management & Sustainability: What it is: AI monitors energy consumption patterns across the plant, identifying opportunities to reduce waste by optimizing machine settings, HVAC systems, and production schedules. How it helps: Lowers energy costs, reduces the factory's carbon footprint, and helps meet sustainability goals.

- Robotics and Intelligent Automation: What it is: AI enhances the capabilities of robots, enabling them to learn new tasks, adapt to changing environments, and work more collaboratively with humans (cobots). How it helps: Increases automation levels for complex tasks, improves safety, and enhances flexibility on the production line.

What are the Benefits of Using AI Manufacturing Software?

Adopting AI software isn't just about implementing new technology; it's about achieving tangible business outcomes:

- Increased Efficiency & Productivity: Automating tasks, optimizing schedules, and reducing downtime lead directly to more output with the same or fewer resources.

- Reduced Operational Costs: Lower energy consumption, less material waste, optimized MRO inventory, and fewer emergency repairs all contribute to a healthier bottom line.

- Improved Product Quality: Consistent, AI-driven inspection and process control lead to fewer defects and higher customer satisfaction.

- Enhanced Agility & Responsiveness: The ability to quickly adapt production schedules to changing demand or supply chain disruptions provides a significant competitive edge.

- Better Decision-Making: AI provides data-driven insights, enabling managers and engineers to make more informed, strategic decisions.

- Increased Worker Safety: AI can monitor for unsafe conditions or take over dangerous tasks, creating a safer working environment.

- Extended Asset Lifespan: Predictive maintenance ensures equipment is maintained optimally, prolonging its operational life and maximizing the return on capital investments.

How to Get Started: Implementing AI Manufacturing Software

Embarking on the AI journey can seem daunting, but a phased, strategic approach makes it manageable and ensures early wins. Here’s a general "how-to" guide:

- Identify Your Biggest Pain Points & Opportunities:

- What to ask: Where are you experiencing the most downtime? What are your biggest sources of quality issues or waste? Where could AI deliver the most immediate and significant ROI? Don't try to boil the ocean. Start by focusing on one or two critical problems that AI is well-suited to solve (predictive maintenance on critical assets is often a great starting point).

- Assess Your Data Readiness:

- What to ask: What data are you currently collecting? Is it clean, accessible, and sufficient for AI models? (AI thrives on data; the better the data, the better the results). You may need to invest in better sensors, data collection infrastructure, or data cleansing processes before fully leveraging AI.

- Define Clear Objectives & Success Metrics:

- What to ask: What does success look like for your initial AI project? Is it a 10% reduction in unplanned downtime? A 5% improvement in first-pass yield? Having clear, measurable goals is essential for justifying the investment and tracking progress.

- Choose the Right Solution & Partner:

- What to consider: Off-the-Shelf vs. Custom: For common problems like predictive maintenance, many excellent off-the-shelf AI software solutions exist. For highly unique challenges, you might explore custom AI development. Integration Capabilities: How easily will the AI software integrate with your existing systems (MES, ERP, CMMS, PLCs)? Look for solutions that offer robust APIs and are designed for interoperability. Scalability: Can the solution scale as your needs grow? Vendor Expertise: Does the vendor understand manufacturing and your specific industry challenges? (This is where Factory AI's approach of understanding unique customer needs to build or recommend solutions, including leveraging an agentic approach for more autonomous systems, becomes relevant, although this blog post focuses on the general "what is" and "how to" of AI software).

- Start with a Pilot Project:

- Select a limited scope for your first AI implementation. This allows you to test the technology, refine your processes, train your team, and demonstrate value quickly. The insights gained from a successful pilot will build confidence and support for broader AI adoption.

- Focus on Change Management & Upskilling:

- AI software will change how people work. It's crucial to involve your team early, explain the benefits (it's about augmenting human capabilities, not replacing jobs), and provide the necessary training to use the new tools effectively.

- Monitor, Iterate, and Scale:

- Once your pilot is live, continuously monitor its performance against your defined metrics. Use the learnings to refine the models and processes. As you demonstrate success, strategically scale the AI solutions to other areas of your operation.

The Future is Intelligent (and Already Arriving)

AI manufacturing software is not a distant dream; it's a present-day reality that is already delivering significant value to manufacturers across all sectors. From the individual machine component to the entire supply chain, AI is providing the intelligence needed to make operations more predictive, productive, and profitable.

While the concept of fully autonomous, "agentic" AI systems making complex decisions (a vision we explore on our Factory AI solutions page) represents the exciting frontier, the journey begins with understanding and implementing the foundational AI software solutions that address today's pressing challenges.

By demystifying what AI manufacturing software is, how it works, and how to begin implementing it, we hope this guide empowers you to take the next steps towards building a smarter, more competitive future for your operations. The tools are here; the time to start is now.

Tim Cheung

Tim Cheung is the CTO and Co-Founder of Factory AI, a startup dedicated to helping manufacturers leverage the power of predictive maintenance. With a passion for customer success and a deep understanding of the industrial sector, Tim is focused on delivering transparent and high-integrity solutions that drive real business outcomes. He is a strong advocate for continuous improvement and believes in the power of data-driven decision-making to optimize operations and prevent costly downtime.