Compressor Predictive Maintenance: The Ultimate 2025 Implementation Playbook

Sep 16, 2025

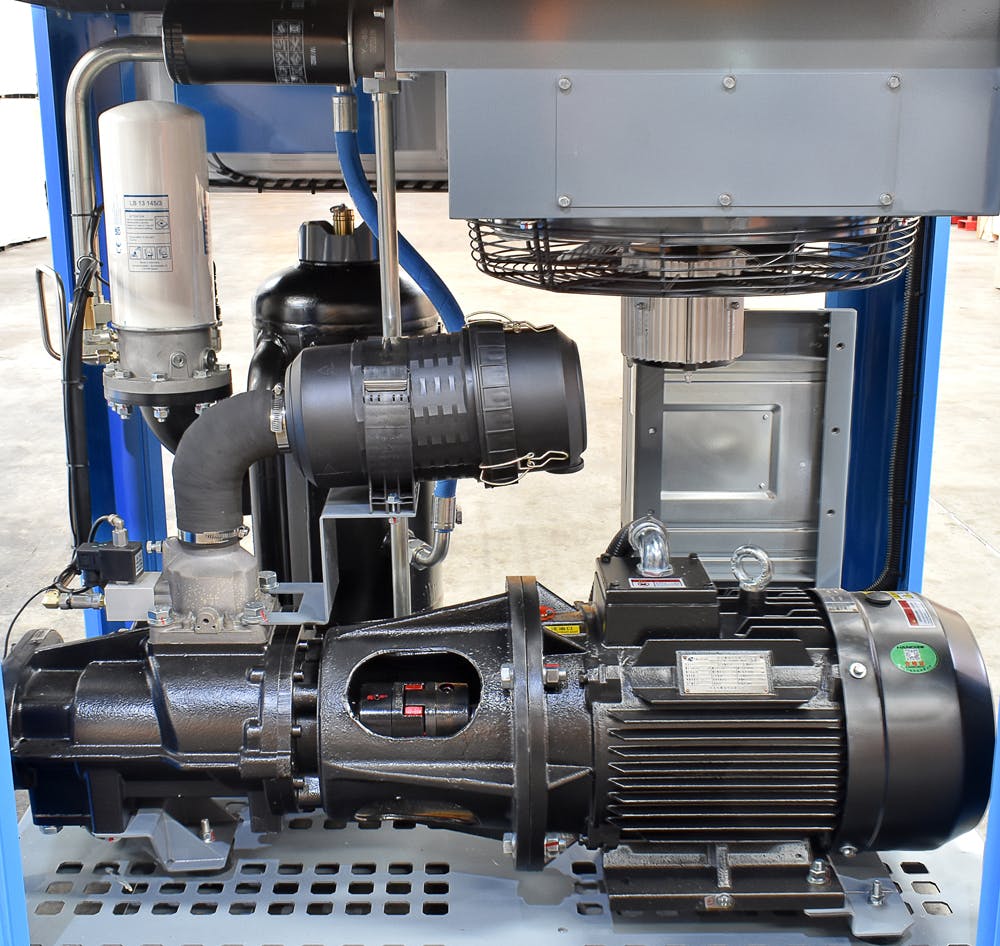

compressor predictive maintenance

Unplanned downtime. It’s the phrase that sends a chill down the spine of any maintenance manager or plant operator. And in the world of industrial operations, few pieces of equipment can bring a facility to a screeching halt faster than a failed air compressor. Often called the "fourth utility" after electricity, water, and natural gas, compressed air is the lifeblood of countless processes, from powering pneumatic tools to controlling automated machinery. When it stops, production stops.

For decades, the standard approach was a mix of running compressors until they broke (reactive maintenance) or replacing parts on a rigid schedule, whether they needed it or not (preventive maintenance). In 2025, these strategies are no longer just inefficient; they are a significant competitive disadvantage. Reactive maintenance is costly and chaotic, while preventive maintenance is wasteful, often leading to unnecessary spending and the introduction of new risks during intrusive servicing.

The solution is a strategic shift to compressor predictive maintenance (PdM). This isn't about fortune-telling; it's about data-driven decision-making. By using advanced monitoring technologies to understand the real-time health of your equipment, you can predict failures before they happen, schedule repairs on your terms, and transform your maintenance department from a cost center into a strategic asset.

This comprehensive guide is your implementation playbook. We’ll move beyond high-level definitions and dive deep into the specific technologies, failure modes, and step-by-step processes you need to build a world-class compressor PdM program that delivers measurable ROI.

Why Predictive Maintenance is Non-Negotiable for Industrial Compressors in 2025

To truly grasp the value of PdM, it's essential to understand where it fits on the maintenance maturity scale and the profound financial impact of compressor reliability.

Beyond Reactive and Preventive: The Maintenance Maturity Curve

Think of maintenance strategies as an evolutionary path:

- Reactive Maintenance (Run-to-Failure): The most basic approach. You fix things only when they break. This leads to maximum downtime, expensive emergency repairs, potential safety incidents, and collateral damage to other components.

- Preventive Maintenance (Time-Based): A significant step up. Maintenance is performed at predetermined intervals (e.g., "change the oil every 2,000 operating hours"). While it prevents many failures, it's inefficient. You might change perfectly good oil, replace bearings with 70% of their life remaining, or miss a rapidly developing fault that occurs between scheduled services.

- Predictive Maintenance (Condition-Based): The modern, intelligent approach. Instead of relying on a calendar, you rely on data. Sensors and analysis techniques monitor the actual condition of the compressor in real-time. Maintenance is only performed when data indicates the beginning of a fault. It's like your car's oil life sensor telling you to get a change based on your driving habits, not just the mileage.

- Prescriptive Maintenance (The Future): The pinnacle of the curve, this emerging strategy uses AI not only to predict a failure but also to recommend the optimal set of actions to mitigate it, considering factors like production schedules, parts inventory, and available labor.

For most organizations in 2025, achieving a robust predictive maintenance program is the most impactful and attainable goal.

The Staggering Costs of Compressor Failure

The true cost of a failed compressor is rarely just the repair bill. The financial bleeding extends far beyond parts and labor.

- Direct Costs: New airend, motor rewind, replacement couplings, seals, and technician labor (often at overtime rates).

- Indirect Costs (The Real Killer):

- Lost Production: This is almost always the largest cost. If your plant produces $50,000 worth of product per hour and a compressor failure shuts down the line for 8 hours, that's a $400,000 revenue loss.

- Wasted Energy: A failing compressor runs inefficiently long before it breaks down completely. A poorly performing unit can easily consume 10-25% more energy, a cost that quietly accumulates on your utility bill.

- Quality Issues: Inconsistent air pressure can lead to product defects, rework, and scrap.

- Safety Hazards: Catastrophic failures can result in flying debris or other dangerous situations for personnel.

The Tangible Benefits of a PdM Program

Implementing a PdM strategy directly counters these costs and delivers clear, quantifiable benefits:

- Increased Uptime: By catching faults early, you can schedule repairs during planned shutdowns, virtually eliminating unplanned downtime.

- Reduced Maintenance Costs: You stop wasting money on unnecessary preventive tasks and parts. Overtime labor for emergency repairs plummets.

- Improved Energy Efficiency: A healthy, well-monitored compressor and air system operate at peak efficiency. PdM techniques like ultrasonic leak detection can slash energy waste by 20-30%.

- Extended Asset Life: By addressing minor issues before they cascade into major failures, you can significantly extend the operational lifespan of your expensive compressor assets.

- Enhanced Safety: Predicting and preventing catastrophic failures makes the entire plant a safer place to work.

Understanding Compressor Failure Modes: The Foundation of Your PdM Strategy

You can't predict a failure if you don't know what you're looking for. The critical first step in any PdM program is to perform a Failure Mode and Effects Analysis (FMEA). This structured process involves identifying all the potential ways a compressor can fail (the modes) and the consequences of those failures (the effects). This analysis directly informs which PdM technologies you need to deploy.

Here’s a breakdown of common failure modes for different compressor types.

Common Failure Modes in Rotary Screw Compressors

These are the workhorses of many industrial facilities. Their reliability hinges on the health of the airend.

- Airend Bearing Failure: This is the #1 cause of catastrophic failure in screw compressors. Wear on the roller or ball bearings leads to increased friction, heat, and eventually, seizure. If undetected, it can destroy the rotors and the entire airend—a repair often costing 60-70% of a new machine.

- Rotor Contact: Caused by bearing failure or ingestion of debris, this is when the male and female rotors touch, leading to severe damage.

- Oil Degradation & Varnish: The oil in a screw compressor lubricates, cools, and seals. Over time, it breaks down, losing viscosity and forming acidic byproducts. This can lead to "varnish," a sticky deposit that clogs coolers, separators, and oil lines, causing overheating and starvation.

- Seal Failure: Shaft seals prevent oil from leaking out and air from leaking in. Their failure leads to oil loss and contamination.

Common Failure Modes in Reciprocating Compressors

These piston-driven machines have more moving parts and different failure characteristics.

- Valve Failure: Intake and discharge valves are under constant stress. They can suffer from fatigue, cracking, warping, or carbon buildup, leading to inefficiency and eventual failure.

- Piston Ring & Cylinder Wear: Wear on piston rings allows compressed air to leak past the piston (blow-by), reducing efficiency. Severe wear can lead to cylinder scoring.

- Bearing and Crankshaft Failure: Similar to any reciprocating engine, connecting rod and main bearing failures can be catastrophic.

- Lubrication System Failure: Clogged lines or a failing oil pump will quickly lead to widespread damage.

Common Failure Modes in Centrifugal Compressors

These dynamic, high-speed machines are common in large-scale process industries.

- Impeller and Diffuser Issues: Imbalance from deposit buildup, erosion from particulates, or corrosion can lead to high vibrations and catastrophic failure at high speeds.

- Surge and Stonewall: These are aerodynamic instabilities. Surge is a violent reversal of flow that can destroy bearings and seals. Stonewall (or choke) is a condition of max flow and low pressure that leads to inefficiency.

- Seal Failure: Sophisticated dry gas seals or labyrinth seals are critical. Their failure can release large amounts of process gas.

The Core Technologies of Compressor Predictive Maintenance

Once your FMEA has identified the likely failure modes, you can select the right technologies to detect their earliest warning signs. A robust program uses a combination of these techniques.

Vibration Analysis: Listening to the Heartbeat of Your Compressor

Vibration analysis is the cornerstone of PdM for any rotating equipment. Every mechanical component vibrates with a unique frequency signature when it's healthy. As a fault develops—like a microscopic pit in a bearing race—it creates distinct, measurable changes in that signature.

- What it Detects:

- Bearing Wear: The most critical application for compressors. Specific frequencies indicate faults on the inner race (BPFI), outer race (BPFO), balls/rollers (BSF), or cage (FTF).

- Imbalance: Uneven weight distribution on rotating parts, like a cooling fan or drive coupling.

- Misalignment: When the motor and compressor shafts are not perfectly aligned.

- Gear Mesh Issues: In gear-driven compressors, it can detect worn or broken teeth.

- Looseness: Detects looseness in mounting bolts or foundations.

- Tools & Techniques:

- Route-Based Analysis: A technician uses a portable data collector to take readings from designated points on each compressor on a regular schedule (e.g., monthly).

- IIoT Sensors: Small, often wireless sensors are permanently mounted to the compressor (typically on the motor and airend bearings). They provide continuous, 24/7 monitoring and stream data to the cloud, enabling much earlier detection of rapidly developing faults.

Oil Analysis: The Blood Test for Compressor Health

If vibration is the EKG, oil analysis is the comprehensive blood panel. A few ounces of lubricant can reveal a tremendous amount about the internal condition of the machine. An effective program, as detailed by organizations like Reliabilityweb, focuses on three key areas.

- What it Reveals:

- Wear Metals: Spectrometry identifies the type and quantity of microscopic metal particles. A spike in iron (Fe) could indicate cylinder wear in a recip, while elevated copper (Cu) and lead (Pb) might point to bearing wear.

- Contaminants: Detects harmful substances like water (causes rust and oil breakdown), dirt/silica (causes abrasive wear), or cross-contamination from other fluids.

- Oil Condition: Measures key properties like Viscosity (the oil's thickness and ability to lubricate), Total Acid Number (TAN) (indicates oil oxidation and degradation), and additive levels. High TAN and viscosity changes are leading indicators of varnish formation in screw compressors.

- Best Practices: The key to useful oil analysis is consistent, clean sampling. Samples should be taken from the same point while the machine is running or just after shutdown. Use a dedicated sampling valve, not a drain plug, to avoid collecting settled sludge.

Ultrasonic Testing: Hearing What Humans Can't

Our ears are limited to a narrow range of sound frequencies. Ultrasonic equipment detects high-frequency sounds produced by friction, turbulence, and electrical discharges.

- Primary Use: Air Leak Detection: This is the single biggest ROI generator for ultrasonics. Compressed air leaks are silent to the naked ear but produce significant high-frequency turbulence. A technician can walk through a plant with an ultrasonic gun and pinpoint the exact location of leaks in pipes, fittings, and couplings. Finding and fixing these leaks can slash a plant's energy bill by 20-30%.

- Secondary Uses:

- Early Bearing Faults: A failing bearing emits high-frequency acoustic emissions long before it shows up as a low-frequency vibration.

- Electrical Faults: Can detect arcing, tracking, and corona discharge in motor control centers and switchgear.

Motor Current Signature Analysis (MCSA): The Compressor's EKG

The electric motor driving the compressor is a powerful sensor in its own right. MCSA uses probes connected to the motor's electrical supply to analyze the signature of the current draw.

- What it Detects:

- Electrical Faults: Broken rotor bars, stator winding faults, and air gap eccentricity in the motor itself.

- Mechanical Faults: The motor's current is affected by the load placed upon it. Therefore, MCSA can often detect mechanical issues within the compressor, such as valve problems in a reciprocating unit that cause uneven loading. It provides a non-intrusive way to gain insight into the driven equipment.

Thermal Imaging (Infrared Thermography)

Infrared cameras visualize temperature, allowing you to spot problems that manifest as heat.

- What it Detects:

- Overheating electrical connections in the motor starter or disconnect.

- Failing couplings that generate heat through friction.

- Clogged or fouled coolers and aftercoolers, which show up as uneven temperature gradients.

- Overheating bearings.

The Ultimate Implementation Playbook: A Step-by-Step Guide

Knowing the technologies is one thing; successfully implementing them is another. Follow this playbook to build a program that lasts.

Step 1: Start Small, Prove Value (Pilot Program)

Don't try to boil the ocean. Attempting to deploy a PdM program across your entire facility at once is a recipe for failure.

- Select Pilot Assets: Choose 2-3 compressors that are highly critical to your operation. A mix of types (e.g., one screw, one recip) can be beneficial. Cataloging these machines in a robust asset management system is a crucial first step.

- Define Success: Set clear, measurable goals for the pilot. Examples: "Detect one impending bearing failure before it becomes catastrophic," or "Reduce energy waste by finding and fixing 20 CFM of air leaks."

- Focus Your Tech: You don't need every technology for your pilot. Start with the highest-impact ones based on your FMEA. For a screw compressor, this is likely vibration analysis for the airend and ultrasonics for system leaks.

Step 2: Conduct a Compressor-Specific FMEA

As discussed earlier, this is your strategic foundation. For your pilot assets, sit down with operators, mechanics, and engineers to brainstorm:

- How can this specific compressor fail? (e.g., Airend bearing spalling)

- What is the effect of that failure? (e.g., Seizure, production shutdown for 3 days)

- What is the likely cause? (e.g., Lubrication breakdown, contamination)

- How can we detect it early? (e.g., Vibration analysis, oil analysis) This exercise maps your failure risks directly to your PdM technology choices.

Step 3: Select and Deploy Your Technology Stack

Based on your FMEA and budget, choose your tools.

- Sensors: Will you use route-based data collection or invest in 24/7 monitoring with IIoT sensors? For critical compressors, the business case for continuous monitoring is often very strong.

- Platform: Data from sensors needs to go somewhere to be analyzed and managed. This is where a modern platform becomes essential. A powerful CMMS software can act as the central hub, integrating data from various PdM sources.

- Integration: Ensure your chosen solution can talk to your existing systems. The goal is a seamless flow of information, not another data silo.

Step 4: Establish Baselines and Alarm Thresholds

A PdM system needs to know what "good" looks like.

- Baseline Data: Once your sensors are installed, collect data for a period while the compressor is running in a known healthy state. This becomes your baseline signature.

- Set Alarms: Using industry standards (like ISO 10816 for vibration) and vendor recommendations, establish two levels of alarms:

- Alert/Alarm: A lower-level threshold indicating a developing issue. This should trigger an investigation.

- Trip/Danger: A higher-level threshold indicating a severe fault that requires immediate attention.

Step 5: Integrate Data into Your Maintenance Workflow

Data is useless if it doesn't lead to action. This is the most critical step.

- Automate Work Orders: The ideal workflow is automated. An "Alert" from a vibration sensor should automatically generate an investigation work order in your CMMS.

- Empower Your Team: The right work order software will route this alert directly to the correct technician's mobile device, complete with asset history, baseline data, and troubleshooting procedures. This closes the loop between detection and action.

Step 6: Train Your Team and Develop Procedures

Your team needs to trust the data and know how to respond.

- Data Interpretation: Provide training on the basics of each technology. A mechanic doesn't need to be a vibration expert, but they should understand what a high-vibration alarm means and why it's important.

- Develop SOPs: Create Standard Operating Procedures for how to respond to different alerts. What are the steps for verifying an alarm? Who needs to be notified?

Step 7: Analyze, Refine, and Scale

Your PdM program is a living system.

- Review and Report: Regularly review the "catches" made by the program. Document the failures you predicted and the costs you avoided.

- Build the Business Case: Use the documented successes and ROI from your pilot program to build a compelling business case for expanding the program to other critical assets across the facility.

The Role of AI and IIoT in Modern Compressor PdM

The technologies and processes of 2025 are supercharging traditional PdM programs, making them more accessible, powerful, and truly predictive.

From Data to Decisions: How IIoT Sensors are Changing the Game

The Industrial Internet of Things (IIoT) has democratized data collection. Small, affordable, wireless sensors can be deployed in minutes, eliminating the need for costly and complex wiring. Instead of monthly data points from a manual route, you get a continuous stream of data, 24/7. This high-frequency data allows you to catch faults that develop rapidly between manual readings, dramatically increasing the reliability of your program.

The Power of AI Predictive Maintenance

The massive amount of data from IIoT sensors is the perfect fuel for Artificial Intelligence (AI) and Machine Learning (ML).

- Beyond Thresholds: Simple alarms are useful, but AI goes deeper. AI predictive maintenance algorithms can learn the unique, complex operating signature of your specific compressor.

- Anomaly Detection: AI can identify subtle deviations from this normal signature that a human might miss, flagging a potential issue long before it breaches a static alarm level.

- Pattern Recognition: AI can correlate multiple data streams. For example, it might learn that on hot days, a slight increase in motor temperature combined with a specific change in the vibration signature is a key precursor to a cooler fouling event.

- Remaining Useful Life (RUL): The holy grail of PdM is predicting not just if a component will fail, but when. AI models can analyze the rate of degradation to forecast the RUL of a bearing or other component, allowing for truly optimized maintenance planning.

Calculating the ROI of Your Compressor PdM Program

To get executive buy-in, you need to speak the language of business: Return on Investment (ROI). The calculation isn't complex and is a powerful tool for justifying your program.

The "Cost of Inaction" Calculation

First, calculate what your current reactive strategy is costing you.

- Formula:

(Annual Unplanned Downtime Hours) x (Cost of Downtime per Hour) = Annual Cost of Failure - Example:

- A critical compressor fails twice a year, causing 6 hours of downtime each time (12 hours total).

- Your plant's cost of downtime is $20,000/hour.

- Cost of Inaction = 12 hours x $20,000/hour = $240,000 per year.

Quantifying the Gains

Next, estimate the savings a PdM program will generate.

- Maintenance Savings: Calculate the reduction in unnecessary PM tasks and emergency overtime. (e.g., saving 80 hours of labor and $5,000 in unneeded parts = $11,000).

- Energy Savings: Use an ultrasonic detector to quantify leaks.

- Formula:

(Total CFM of Leaks) x (Annual Operating Hours) x (Energy Cost per CFM) - The Compressed Air & Gas Institute (CAGI) estimates it costs roughly $1 per CFM for an entire year at $0.05/kWh. At $0.10/kWh, it's $2 per CFM.

- Example: You find and fix 50 CFM of leaks. At $0.10/kWh, your annual savings are 50 CFM x $2 = $10,000 per year.

- Formula:

- Uptime Value: If your PdM program prevents just one of the two annual failures from the example above, you've saved 6 hours of downtime.

- Value = 6 hours x $20,000/hour = $120,000

The Investment Side of the Equation

Total up the costs for your pilot program.

- Hardware: IIoT sensors, gateways, etc. (e.g., $5,000)

- Software: Annual subscription for the PdM/CMMS platform (e.g., $4,000)

- Training & Implementation: (e.g., $3,000)

- Total First-Year Investment = $12,000

Putting It All Together: A Sample ROI

- Total Annual Gains: $11,000 (Maint.) + $10,000 (Energy) + $120,000 (Uptime) = $141,000

- First-Year Net Return: $141,000 (Gains) - $12,000 (Investment) = $129,000

- First-Year ROI: ($129,000 / $12,000) x 100 = 1075%

A four-figure ROI is not unrealistic for a well-executed compressor PdM program, demonstrating its immense power to impact the bottom line.

Your Partner in Compressor Reliability

Moving from a reactive firefighting mode to a proactive, predictive strategy is one of the most valuable initiatives any industrial facility can undertake. For compressed air systems, it's not a luxury—it's a strategic necessity for competitiveness and profitability in 2025.

By following this playbook—starting with a focused pilot, building on a foundation of FMEA, leveraging the right mix of modern technology, and integrating it all into your daily workflow—you can eliminate unplanned downtime, slash energy costs, and extend the life of your critical assets.

The journey begins with the first step. It's time to stop reacting to compressor failures and start predicting them.

Ready to move beyond reactive maintenance and unlock the true potential of your compressed air systems? Explore how our predictive maintenance solutions for compressors can provide the technology and platform to build your world-class reliability program.