Best Free CMMS Options for Manufacturing Maintenance Teams (2025)

Aug 9, 2025

Why the CMMS Decision Matters More Than Ever

Imagine a bakery that runs two shifts a day, producing thousands of units of packaged goods. On Monday, a key mixer breaks down unexpectedly. The maintenance team scrambles to diagnose the issue, parts are ordered in a rush, and production is down for four hours. The loss isn’t just the wasted dough — it’s missed deliveries, overtime costs, and a ripple effect on downstream orders.

Now imagine that same bakery with a CMMS in place that not only tracked every asset’s history but also prompted preventive tasks before the mixer failed. The downtime is avoided, the schedule stays intact, and costs are contained.

This is the promise of a CMMS — a single platform where all maintenance activities live, where data drives decision-making, and where you can shift from reactive firefighting to proactive planning.

In 2025, CMMS adoption is no longer optional for competitive manufacturers. Industry 4.0 trends, supply chain pressures, and rising equipment complexity make manual systems unsustainable. But the challenge remains: how do you choose the right CMMS when budgets are tight and expectations are high?

Free and low-cost CMMS tools are often the entry point. They give teams a way to digitalise maintenance without the upfront investment. For agri-food manufacturing — dairy, seafood, baked goods, FMCG — where margins are slim and equipment is diverse, the idea of “free” is tempting. Yet the reality is more nuanced.

The Problem with “Free” CMMS Solutions

The search for a free CMMS usually starts with good intentions. You want to replace spreadsheets, paper work orders, or a patchwork of emails and radio calls. You don’t yet have budget approval for a paid platform, so you look for free options to prove the concept.

However, “free” almost always comes with trade-offs.

1. Feature Limitations That Stall Growth

Many free tiers offer only a fraction of the full platform’s capability. You might get unlimited work orders but no preventive scheduling. Or you can schedule PMs but not attach files, run reports, or track parts inventory.

This means that just as your team starts to see benefits, you hit a ceiling. Moving to a paid tier can feel like starting over — re-entering data, retraining staff, and adjusting workflows.

2. User and Asset Caps

A common restriction is the number of users or assets. Some free plans allow only two or three users. Others limit asset records to a few dozen. That’s fine for a pilot in a small maintenance shop but unworkable for plants with multiple shifts, operators, and dozens of machines.

In agri-food, where assets range from refrigeration compressors to conveyor belts to automated fillers, these limits can block real adoption.

3. Support Gaps

Paid CMMS vendors typically offer live chat, phone, or dedicated account managers. Free users often get community forums or delayed email support. If your production line is down and you can’t assign a work order because of a technical glitch, waiting 48 hours for a reply is unacceptable.

4. Integration Barriers

Modern manufacturing increasingly relies on connected systems — ERP, MES, SCADA, IoT sensors. Many free CMMS tools don’t integrate with these out of the box. That means duplicate data entry, inconsistent records, and missed opportunities for automation.

5. Adoption Risks

Even the best-designed CMMS requires a cultural shift. Technicians need to log work in real time, planners need to schedule proactively, and managers need to review the data regularly. If the tool is clunky, confusing, or doesn’t match how people work, adoption stalls.

Free CMMS platforms often cut corners on UI/UX design in the free tier, focusing their best features on paying customers. This can lead to a false negative: “We tried a CMMS and it didn’t work,” when in reality it was the wrong tool for the job.

The Hidden Cost of Free

On the surface, a free CMMS saves subscription fees. But the hidden cost is the time and efficiency lost when the tool can’t keep up.

Consider:

- Missed preventive maintenance due to scheduling limits, leading to breakdowns that cost thousands in downtime.

- Double handling of data because the free CMMS doesn’t integrate with purchasing or inventory systems.

- Low technician compliance if the mobile app is clumsy or slow, meaning your data is incomplete and unreliable.

Over months or years, these inefficiencies can easily cost more than a paid CMMS subscription.

Why Agri-Food Maintenance Has Unique CMMS Needs

While CMMS principles apply across manufacturing, agri-food brings distinct challenges:

- Diverse asset types. From food-grade conveyors to refrigeration systems, each with different maintenance profiles.

- Strict compliance. Hygiene and safety regulations demand rigorous record-keeping and audit readiness.

- Seasonality. Demand spikes (e.g., holiday baking) can strain equipment and staff.

- Environmental conditions. Moisture, temperature extremes, and wash-down processes can affect asset reliability.

- High downtime costs. Perishable products mean that delays can lead to waste, not just lost output.

A CMMS for agri-food must therefore be adaptable, easy to update on the floor, and capable of handling a variety of maintenance triggers — from usage hours to hygiene cycles.

Insight: What Makes a Free CMMS Worth Considering?

Not all free CMMS tools are created equal. Some are little more than glorified task lists. Others offer surprisingly robust features but hide key functions behind paywalls.

Based on our experience in agri-food manufacturing, a worthwhile free CMMS should:

1. Support mobile use without compromise.

Technicians should be able to create, update, and close work orders directly from their phones or tablets, with photos and notes.

2. Allow realistic asset and user counts.

Even a small plant can have 100+ assets and a dozen people needing access.

3. Include preventive maintenance scheduling.

Reactive-only systems keep you in firefighting mode.

4. Offer at least basic reporting.

You need to show results to justify future investment — whether in the form of reduced downtime, improved PM compliance, or cost savings.

5. Be intuitive.

The learning curve should be minimal, especially for frontline staff who may not have extensive IT training.

If a free CMMS meets these criteria, it can serve as a bridge — proving the value of digital maintenance and paving the way for a more capable solution, like Factory AI Prevent, when the time is right.

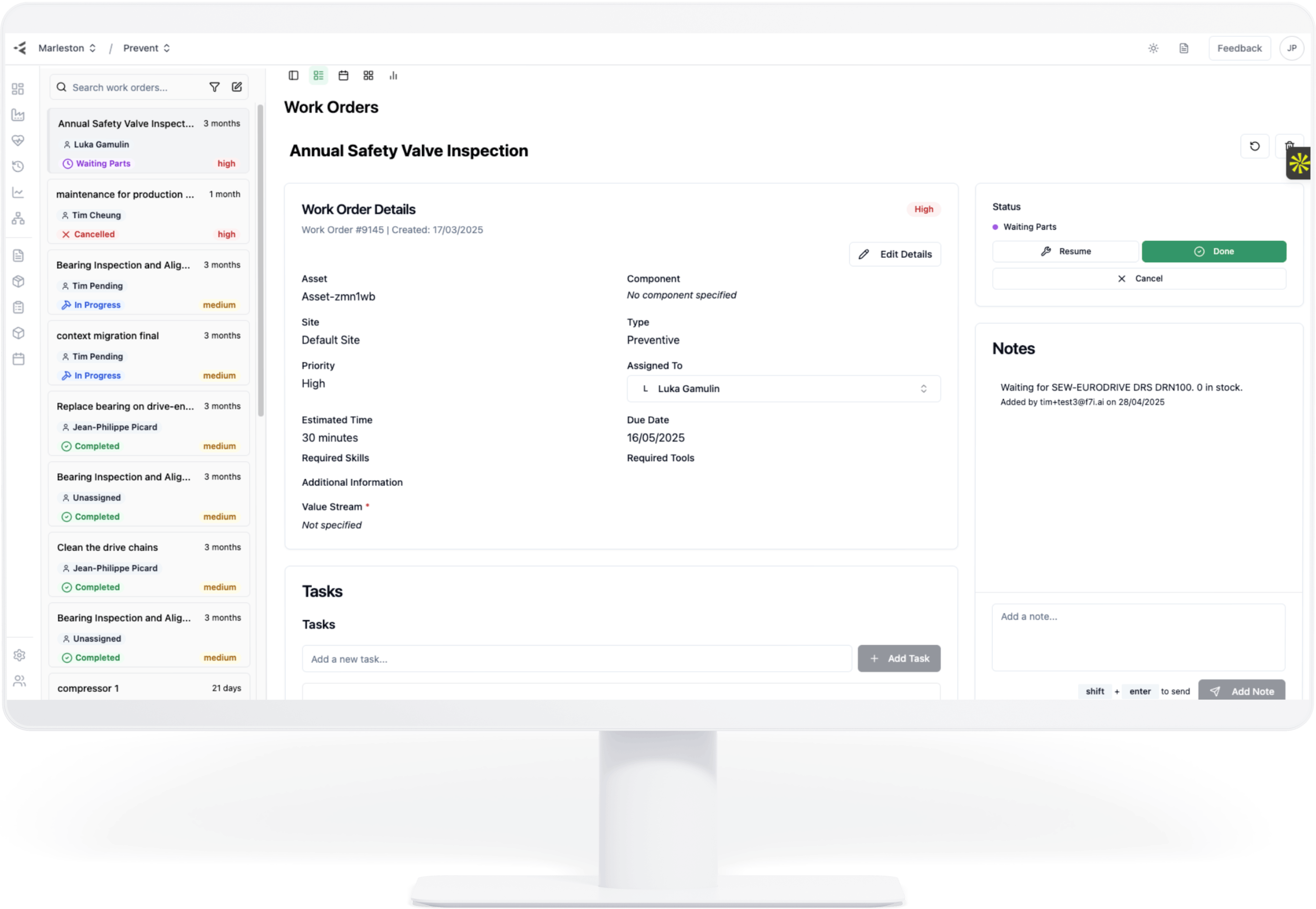

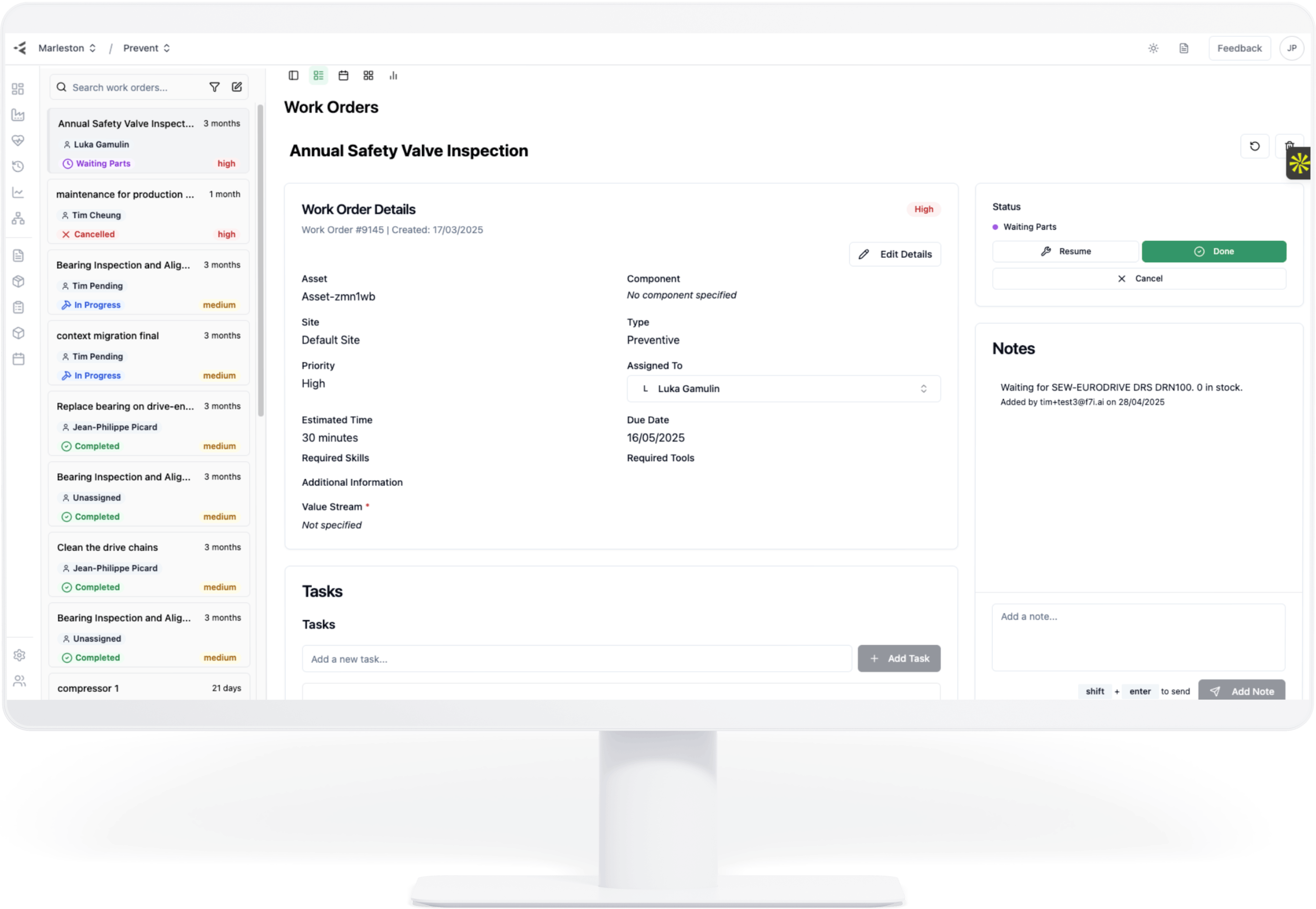

1. Factory AI Prevent — Best Overall Choice

Factory AI Prevent is free to use. We offer a free plan designed to give maintenance teams a clear starting point without financial commitment. You can start using it right now by creating your account here.This makes it ideal for smaller plants, pilot projects, or teams wanting to trial predictive and AI-driven capabilities before scaling up. It’s more than a CMMS: it’s a reliability platform designed to help frontline teams prevent failures before they occur.

The Factory AI free plan includes:

- 5 work orders per month — enough to manage smaller workloads or trial usage on a single production line

- 10 assets — track critical machines, refrigeration units, or other high-priority equipment

- 5 AI credits — run AI-powered maintenance insights and failure mode analysis without specialist knowledge

- Basic work order management — create, assign, and close jobs from desktop or mobile

While the free plan has clear limits, it allows teams to experience Prevent’s interface, speed of deployment, and AI-assisted features firsthand.

Why it stands out

Even at the free tier, Prevent is more than a work order tracker. It’s built for the realities of agri-food manufacturing: mixed asset types, regulatory record-keeping, and frontline adoption. For teams ready to expand beyond the free limits, the paid version removes caps and unlocks full CMMS, predictive maintenance, and analytics capabilities — all without changing platforms or retraining staff.

Key strengths

- Affordable structure. One simple bundled subscription covers all users and assets. No surprise charges as your team grows.

- Full reliability platform. Prevent includes all the traditional CMMS capabilities — work orders, preventive scheduling, asset hierarchies, inventory management — plus predictive insights and analytics.

- AI-driven decisions. The system analyses incoming sensor data, usage history, and contextual information to identify likely failure modes. This requires no vibration analysis expertise.

- Rapid deployment. Sensors and software can be up and running in under 30 minutes per asset. This allows entire plants to go live in days, not months.

- Sensor-agnostic. Works with existing sensors or Factory AI’s own hardware. This makes retrofitting straightforward.

- Works offline. Prevent is designed to operate in environments without reliable Wi-Fi or deep IT infrastructure.

- ROI under six months. Measurable reductions in downtime and maintenance spend in less than half a year.

Why it matters for agri-food

A seafood processor, for example, can’t afford unexpected failures in refrigeration. Prevent’s AI-based monitoring alerts teams to changes in asset behaviour before failures happen. This protects product integrity and keeps compliance records audit-ready.

Common objection handled

"We can’t afford a paid CMMS."

The cost of unplanned downtime — lost production, wasted product, overtime pay — can exceed a year of Prevent’s subscription in a single incident. When you factor in reduced firefighting and better planning, the subscription often pays for itself several times over.

2. Limble CMMS — Best for Asset Management

Limble is a well-established CMMS provider with a free Basic plan that is generous for asset tracking.

Features

- Unlimited assets, even on the free plan — a rarity in the CMMS market.

- Custom fields and asset hierarchies to reflect real-world plant layouts (e.g., plant → line → machine → component).

- Mobile app for Android and iOS, allowing on-floor updates.

- Work order management with status tracking.

Limitations

- Preventive maintenance scheduling is basic in the free plan.

- Advanced reporting, custom dashboards, and IoT integrations require a paid subscription.

- Limited automation options without upgrades.

Use-case scenario

A small dairy with multiple pasteurisers and packaging machines can use Limble to keep an accurate asset register and log basic maintenance work. However, once the team needs complex PM schedules tied to production cycles, a paid plan or another platform may be necessary.

Objection handled

"We’ll just use Limble forever — why pay?"

That’s fine if you only need static asset tracking and basic work orders. But if you expect to scale into analytics, predictive triggers, or integration with other systems, the upgrade will be unavoidable.

3. Fiix — AI-Powered Work-Order Reporting

Fiix has built its reputation on usability and modern design. Its free tier is aimed at small teams transitioning from paper or spreadsheets.

Features

- Mobile-first design for easy on-floor adoption.

- AI-driven analysis of work orders — spotting patterns in asset failures and task completion.

- Integrations with popular business systems on paid tiers.

- Preventive maintenance scheduling in a simple calendar view.

Limitations

- Free tier restricts number of work orders per month.

- Reporting tools are basic compared to paid versions.

- Limited configuration options in the free plan.

Use-case scenario

A mid-size bakery running three production lines can start with Fiix to digitise maintenance requests from operators and track work order turnaround. As the team starts to analyse downtime trends, they may need to upgrade to unlock more AI features.

Objection handled

"We need AI but can’t pay."

Fiix’s free AI features give you a taste, but advanced predictive capability is not included without a subscription. For continuous AI-based reliability, a platform like Prevent is a better long-term option.

4. SuperCMMS — Forever-Free Enterprise-Grade

This is one of the most surprising entries on the list. Despite being relatively unknown, SuperCMMS offers an impressive range of features at no cost for small teams.

Features

- Asset management with photos, serial numbers, and custom attributes.

- Preventive maintenance scheduling with calendar or meter-based triggers.

- Inventory management linked to work orders.

- QR codes for quick asset lookup.

- API access for integrations.

- Audit trails for compliance.

Limitations

- Free plan is capped at three team members.

- Limited brand recognition means fewer community resources.

- Support is slower than paid CMMS options.

Use-case scenario

A seafood processing facility with a lean maintenance team can manage assets, PMs, and inventory with SuperCMMS — as long as they stay under the user limit. For larger teams, licensing would be required or another platform chosen.

Objection handled

"We want big-name vendors only."

Brand recognition can be reassuring, but functionality is what matters most. For small, self-sufficient teams, SuperCMMS delivers at a fraction of the cost.

5. Atlas CMMS — True Open Source

Atlas is for teams that value complete control over their software. As open source, it can be customised down to the code level.

Features

- Full CMMS core: assets, work orders, preventive maintenance, inventory.

- No vendor lock-in — you own the code.

- Flexible hosting: on-premise or cloud.

- Customisable UI, workflows, and integrations.

Limitations

- Requires in-house IT expertise to install, host, and maintain.

- No dedicated vendor support unless you contract it separately.

- Updates and security patches are your responsibility.

Use-case scenario

A large agri-food company with its own IT department could deploy Atlas to multiple sites, integrating it with existing ERP and production systems. The flexibility is unmatched, but so is the technical overhead.

Objection handled

"We don’t have IT resources."

Then Atlas is not for you. Without in-house skills, the cost of outsourcing support can exceed that of a paid CMMS with built-in hosting and updates.

6. MaintainX — Best for Mobile-First Teams

MaintainX is known for its intuitive mobile interface and fast adoption on the plant floor.

Features

- Real-time messaging between maintenance and operations staff.

- Unlimited work orders on the free plan.

- Photo attachments and comments within work orders.

- Asset histories accessible from mobile devices.

Limitations

- Preventive maintenance automation is basic in the free version.

- Offline functionality is limited unless on a paid tier.

- Reporting is minimal without upgrading.

Use-case scenario

A vegetable processing facility with multiple production areas and operators dispersed across them can use MaintainX to quickly capture maintenance needs. Operators can take a photo, log a request, and message maintenance in real time.

Objection handled

"Free MaintainX will handle everything."

It works well for basic work order flow, but if you need structured PM programmes, advanced analytics, or offline capabilities, you’ll need to upgrade.

A Decision Framework for Selecting Your CMMS

Free CMMS tools can be an excellent starting point, but they’re not all created equal. A structured decision framework helps cut through marketing claims and match the tool to your operational reality.

Step 1: Define your current pain points.

Are you struggling with unplanned downtime, missing compliance records, or simply drowning in paper work orders? Your dominant pain point should guide your priority features.

Step 2: Map your operational scale.

List the number of assets, sites, and maintenance staff who will need access. This will immediately highlight whether a free tier’s user or asset limits are feasible.

Step 3: Identify your growth horizon.

Will your maintenance needs grow in the next 12–18 months? If you know you’ll soon need advanced reporting, integrations, or predictive analytics, it may be better to start with a platform that offers these in paid tiers without forcing a migration.

Step 4: Evaluate technical capacity.

If your plant has an in-house IT team, an open-source option like Atlas might be viable. Without that, you’ll want a hosted service with strong support.

Step 5: Match to adoption needs.

In agri-food, frontline adoption is critical. If the UI is complex or slow on mobile, you will lose compliance. Tools like MaintainX excel here; Factory AI Prevent also prioritises technician-first design.

Quick Selection Guide

If you need...Consider...Predictive maintenance + ROI in <6 monthsFactory AI PreventUnlimited asset tracking in a free planLimble CMMSMobile-first quick adoptionMaintainXForever-free enterprise-grade featuresSuperCMMSOpen-source flexibility + in-house ITAtlas CMMSAI-powered reporting without full PdMFiix

Implementation Strategies for Free CMMS Tools

A CMMS is only as good as the way you implement it. Even a free tool can deliver impressive results if rolled out thoughtfully.

1. Start with a Pilot

Choose a single production line or asset category as your pilot scope. This keeps the project manageable and allows you to iron out workflow issues before scaling. For example, a seafood processor might start with refrigeration units, tracking all PMs, work orders, and downtime events for three months.

2. Build Your Asset Register First

A CMMS is built on accurate asset data. Before assigning work orders, ensure every asset in scope has:

- A unique ID

- Make, model, and serial number

- Location

- Key maintenance tasks

- Critical spares list

This foundation prevents duplication and confusion later.

3. Create Preventive Maintenance Schedules Early

Don’t wait until the system is live to think about PMs. Use manufacturer recommendations, maintenance logs, and operator input to build your schedules. Even free CMMS tools often allow simple recurring tasks, which can be expanded over time.

4. Train for Daily Use

The biggest failure point in CMMS adoption is lack of use. Conduct short, practical training sessions focused on everyday tasks: raising a work order, closing a task, attaching a photo. For large shifts, nominate “CMMS champions” to support adoption.

5. Measure and Review

From day one, decide which KPIs matter:

- Preventive vs reactive work ratio

- Mean time to repair (MTTR)

- Mean time between failures (MTBF)

- PM compliance rate

Review these monthly. If your free CMMS can’t report them, track them manually until you upgrade.

Common Objections — and How to Address Them

Even the best CMMS can face resistance. Here are some frequent pushbacks and practical counters.

Objection 1: “We don’t have time to enter data.”

Counter: Start small — even logging only breakdowns provides value. Over time, show how logged data prevents future failures and reduces reactive work.

Objection 2: “Free is good enough.”

Counter: It may be — for now. But have a plan for when you outgrow the limits. Downtime caused by missing PMs or lack of integration can quickly make “free” the most expensive option.

Objection 3: “Technicians won’t use it.”

Counter: Choose a CMMS with a mobile-first design and minimal clicks to complete a task. Involve technicians in the selection process to increase buy-in.

Objection 4: “Paid CMMS is too costly.”

Counter: Compare subscription cost to the expense of one major breakdown. In many cases, a single avoided failure pays for a year of a paid CMMS like Factory AI Prevent.

Building the Business Case for Upgrading

For many plants, a free CMMS is the starting point. Over time, you may need:

- Predictive maintenance capabilities

- AI-driven analytics

- Unrestricted users and assets

- Advanced integrations

This is where moving to a platform like Factory AI Prevent makes strategic sense. The business case often includes:

- Quantified downtime reduction.

If Prevent avoids just one major failure a year, the savings can exceed the subscription fee. - Improved compliance.

Audit-ready records reduce regulatory risk. - Frontline empowerment.

Simple workflows free up technicians for higher-value tasks.

Why Factory AI Prevent Is the Logical Next Step

Once you’ve proven CMMS value with a free tool, the next question is how to extend that value without losing momentum. Prevent offers:

- All core CMMS functions, so there’s no loss of capability in transition.

- Predictive monitoring without needing vibration experts.

- Sub-30-minute asset setup to maintain rollout speed.

- Offline operation and sensor-agnostic design, perfect for agri-food plants with patchy connectivity.

In other words, Prevent is built for the realities of manufacturing, not just the theory.

Final Recommendations

- If you have no CMMS at all, start with a free tool that fits your current scale such as Factory AI's Prevent.

- Focus on adoption first — features are useless if no one uses them.

- Review your needs every quarter, and be ready to upgrade when limitations begin costing you money.

- When predictive insight, ROI, and deployment speed matter most, Factory AI Prevent should be at the top of your shortlist.

Call to Action

Your maintenance strategy is only as strong as the tools that support it. Free CMMS platforms can help you get started, but their limits are inevitable. If your plant’s reliability, compliance, and cost control can’t afford those limits, it’s time to look at a smarter solution.

Factory AI Prevent is designed to deploy fast, work with your existing assets, and deliver ROI in under six months. It’s more than a CMMS — it’s a frontline-ready reliability platform that empowers your team to prevent failures before they happen.

Book a demo today and see how Prevent can reduce downtime, streamline maintenance workflows, and give you the reliability edge in competitive manufacturing.